Reference Manual

00809-0200-4101, Rev AA

July 2008

2-13

Rosemount 2051

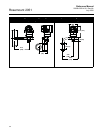

Flange Bolts

The 2051 is shipped with a Coplanar flange installed with four 1.75-in. (44

mm) flange bolts. See Figure 2-6 and Figure 2-7 on pages 2-14 and 2-14.

Stainless steel bolts are coated with a lubricant to ease installation. Carbon

steel bolts do not require lubrication. No additional lubricant should be applied

when installing either type of bolt. Bolts are identified by their head markings:

Bolt Installation

Only use bolts supplied with the 2051 or provided by Emerson Process

Management as spare parts. When installing the transmitter to one of the

optional mounting brackets, torque the bolts to 125 in-lb. (0,9 N-m). Use

the following bolt installation procedure:

1. Finger-tighten the bolts.

2. Torque the bolts to the initial torque value using a crossing pattern.

3. Torque the bolts to the final torque value using the same

crossing pattern.

Torque values for the flange and manifold adapter bolts are as follows:

Table 2-3. Bolt Installation

Torque Values

Carbon Steel (CS) Head Markings

B7M

B8M

F593_*

Stainless Steel (SST) Head Markings

* The last digit in the F593_ head marking

may be any letter between A and M.

316

See “Safety Messages” on page 2-1 for complete warning information.

Bolt Material Initial Torque Value Final Torque Value

CS-ASTM-A449 Standard 300 in.-lb (34 N-m) 650 in.-lb (73 N-m)

316 SST—Option L4 150 in.-lb (17 N-m) 300 in.-lb (34 N-m)

ASTM-A-193-B7M—Option L5 300 in.-lb (34 N-m) 650 in.-lb (73 N-m)

ASTM-A-193 Class 2, Grade

B8M—Option L8

150 in.-lb (17 N-m) 300 in.-lb (34 N-m)