114

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Kirby Morgan 37 & 57

16) Install the o-ring in the packing nut.

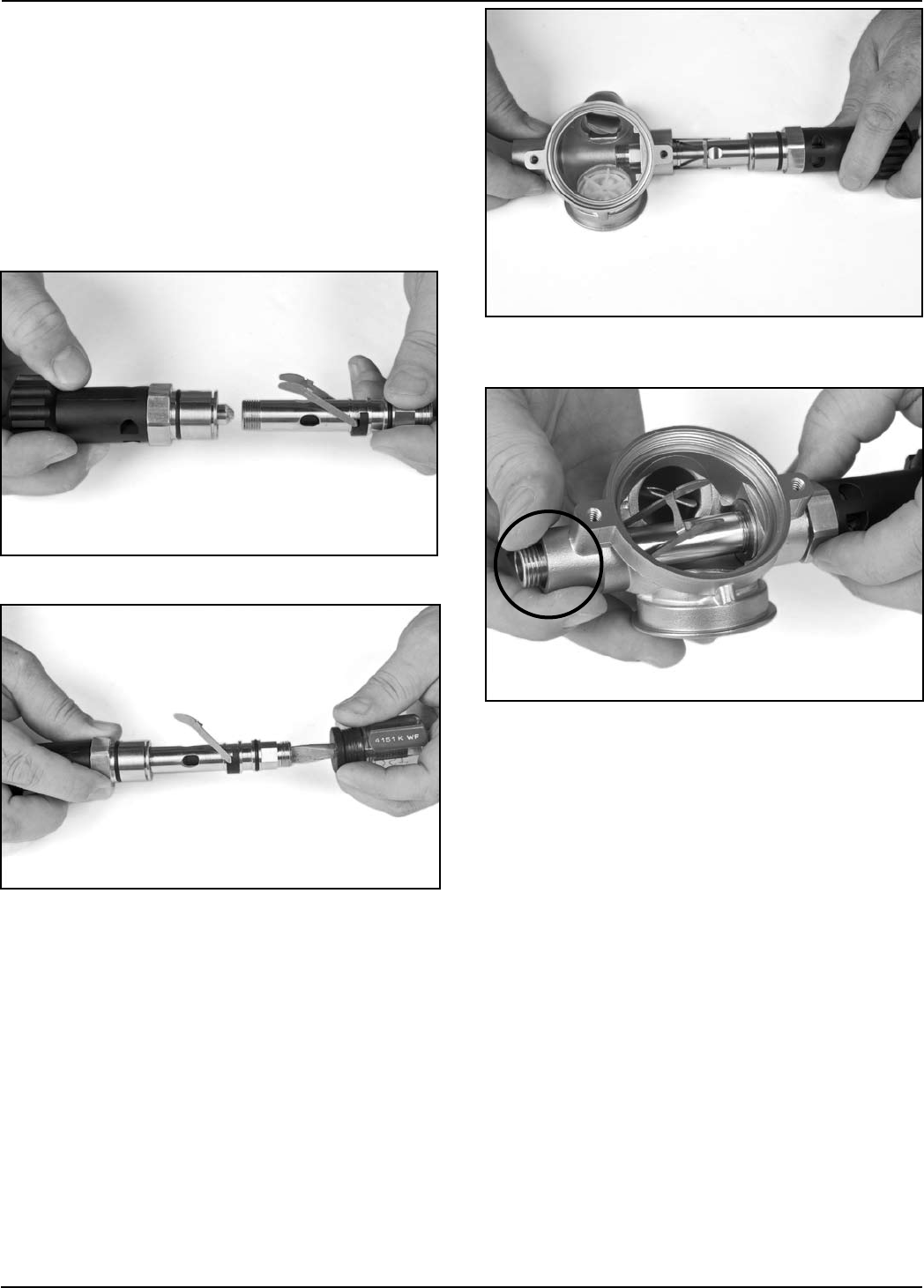

17) Fit the flattened end of the adjustment shaft into

the flex knob.

18) Screw the adjustment shaft into the packing nut

until it clicks.

19) Screw the packing nut and the entire flex knob

assembly onto the main tube until it is hand tight.

Screw the flex knob assembly onto the main tube.

20) Screw the adjustment nipple into the main tube

while watching for any movement of the lever (198).

As soon as you see any movement of the lever, stop

turning the nipple. Turn the nipple just enough so

that the lever drops 1/8 inch.

21) Allow this assembly to sit for 24 hours so that

the seat conforms to the adjustment nipple.

22) Carefully slide the main tube and associated parts

into the regulator body.

Screw the adjustment nipple into the open end of

the main tube.

Slide the main tube and associated parts into the

regulator body.

23) If the main tube assembly has been properly

installed in the regulator, the lever must be pointing

straight up so that it will make contact with the dia-

phragm at the correct point. Note that the threaded

end of the main tube where the bent tube adapter

connects to it protrudes from the regulator body.

24) The flats on the main tube should be even with

the outside end tube of the regulator body. If they are

not, gently rotate the main tube assembly until flat

surface on the main tube align with the flat surfaces

inside the tube on the regulator body.

26) Loosen the packing nut from one to one and a

half turns.

27) Install the bent tube adapter and torque to 30

inch pounds.

The end of the threads on the main tube should be

flush with the opening of the tube on the side of the

regulator body.