70

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Kirby Morgan 37 & 57

7.3 Side Block Assembly

7.3.1 General

The side block should be overhauled at least annually,

or whenever components show signs of wear, damage

or do not function smoothly or properly. Minimum

replacement components during overhaul includes

all O-rings. A repair kit is available for replacement

parts (Part #525-311).

The side block does not require removal from the

helmet each time an overhaul is being conducted

providing inspection of the internal passages does not

reveal contamination or excessive corrosion. How-

ever, the side block should be completely removed at

least every three years of active use to ensure fasteners

are not corroded or frozen.

The side block assembly is held in place on the helmet

shell by a stud, flat washer, lock washer, nut, and a

machine screw. The screw does some securing but its

main function is to prevent rotation of the side block.

The stud also extends into the interior of the helmet

shell far enough to secure the air train by means of

the washer and nut.

The air train cup that fits over the stud is made of

soft brass and cannot be used for a bearing surface to

mount the side block. RTV silicone rubber compound

is used to form a gas tight seal between the side block

and the exterior of the helmet shell.

7.3.2 Side Block Assembly Removal

Tools Required:

7/16,11/16, and 7/8 inch Open End Wrenches

11/16 and 7/8 inch Open End Wrench Attachment on

Torque Wrench

1/4 inch Flat Blade Stubby Screwdriver

The bent tube assembly must be entirely removed be-

fore removal of the side block assembly is started.

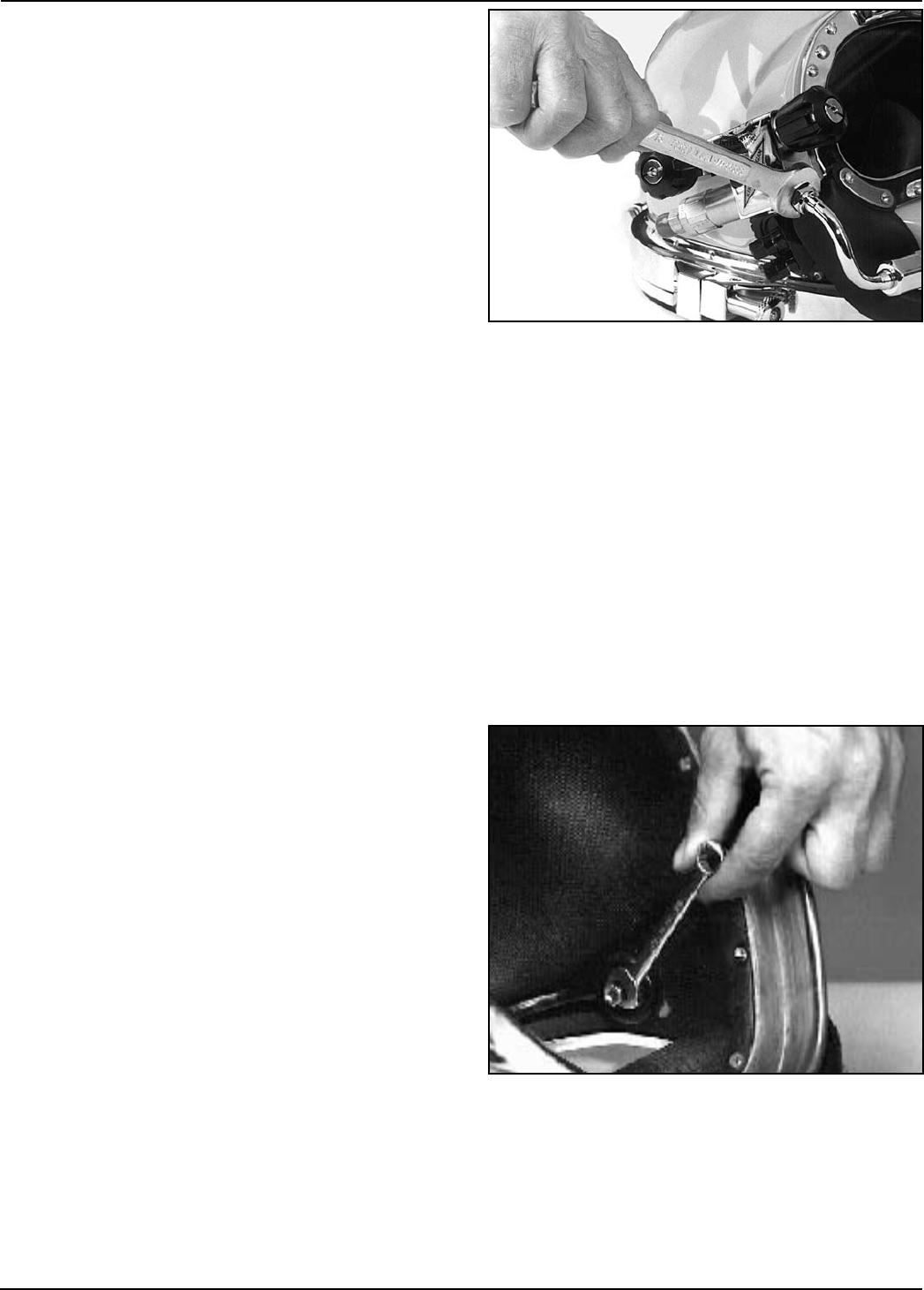

1) Completely unscrew the bent tube assembly nut

(14) from the side block.

2) Using two wrenches, hold the nut at the regulator

end of the bent tube assembly with the first wrench.

With the other wrench, loosen the jam nut (100) by

turning the wrench DOWN.

3) Unscrew the bent tube nut until it comes free, then

pull the bent tube assembly straight out of the regula-

tor inlet nipple.

4) The side block assembly is ready to be separated

from the helmet shell at this time.

7.3.3 Separating the Side Block Assembly

from the Helmet Shell

Tools Required:

Putty Knife

7/16 inch Open End Wrench

1/4 inch Flat Blade Stubby Screwdriver

1) Removal of the side block assembly requires re-

moving the air train.

2) Remove the nut and washer that secure the air train,

then the air train itself.

3) The stud nut is removed next, with the lock washer

and flat washer.

Loosening the nut that holds the air train.

Loosening the bent tube from the side block.

4) Next, the alignment screw is removed.

NOTE: The alignment screw is located in a recess in

the fiberglass next to the stud. This recess is normally

filled with RTV. The RTV must be scraped free to reveal

the screw.