16

Footplate

Clamps

Removable

Footboard

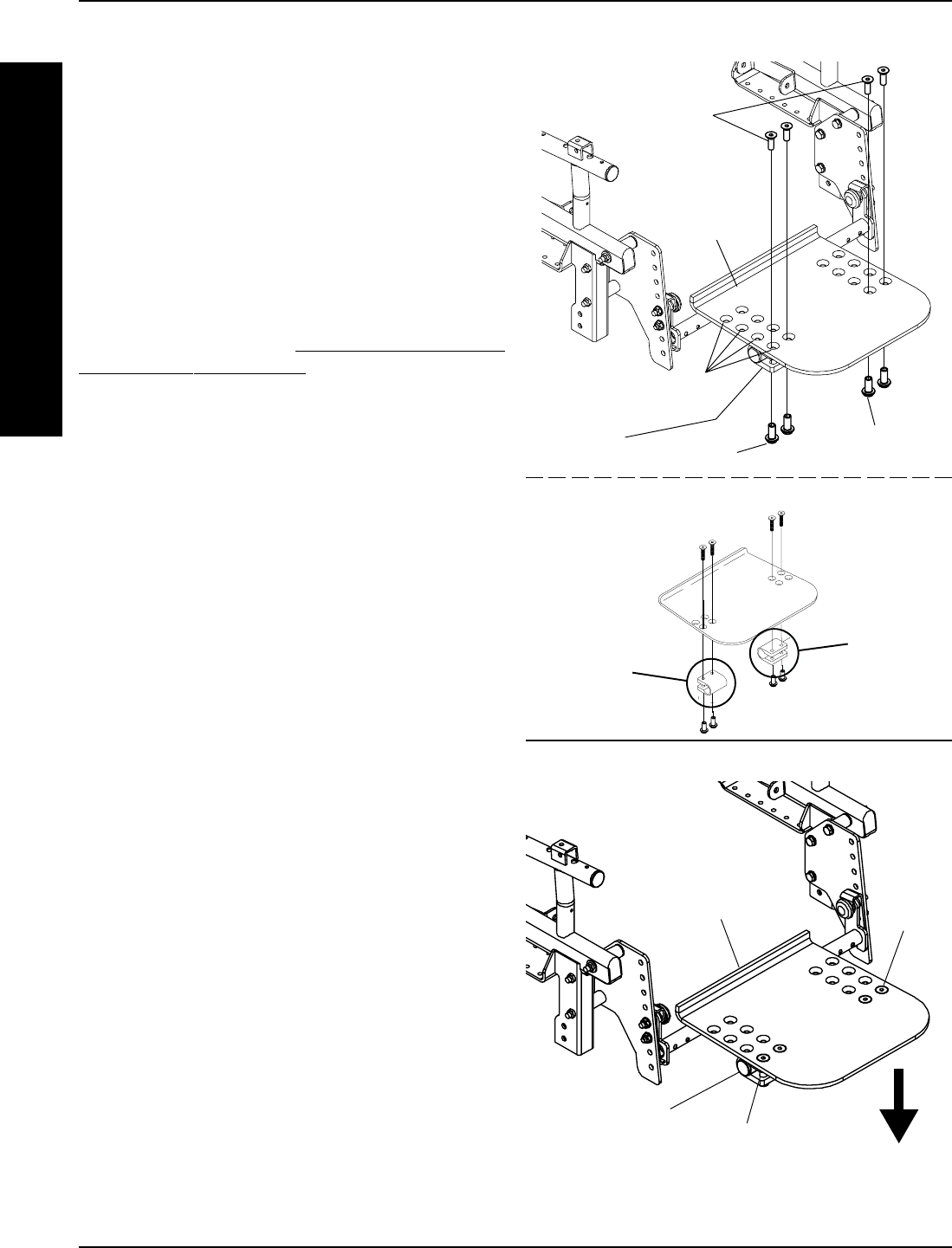

ADJUSTING DEPTH

Mounting

Positions

Flat Head Screws

Barrel Nut

Barrel Nut

DETAIL "A"

Proper

Footplate

Clamp

Position for

MWD

Wheelchairs

Proper

Footplate

Clamp

Position for

FWD

Wheelchairs

ADJUSTING THE REMOVABLE

FOOTBOARD

NOTE:This footboard assembly is available on models

built AFTER 3/1/00. Refer to ADJUSTING THE FLIP-UP

REMOVABLE FOOTBOARD for the footboard assem-

bly on models built BEFORE 3/1/00 in this procedure of

the manual.

NOTE: The following procedures are for both FWD and

MWD fwheelchairs, unless otherwise noted.

Depth (FIGURE 3)

NOTE: There is no footboard depth adjustment for 16-

inch wide MWD wheelchairs.

1. Remove the four (4) flat head screws and barrel nuts

that secure the removable footboard to the two (2)

footplate clamps.

2. Move the removable footboard to one (1) of the four (4)

positions.

NOTE: Before reinstalling the four (4) flat head screws,

make sure the footplate clamps are in the proper position

as shown in DETAIL "A".

3. Reinstall the four (4) flat head screws and barrel nuts

that secure the removable footboard to the two (2)

footplate clamps. Tighten securely.

Angle

ADJUSTING FOOTBOARD ANGLE (FIGURE 3).

1. Loosen, but do not remove, the four (4) flat head screws

and barrel nuts that secure the removable footboard

to the two (2) footplate clamps.

NOTE: Because of the two (2) support tubes, the angle of

the removable footboard can be adjusted downward ONLY.

2. Grasp the front of the removable footboard and rotate

it DOWNWARD until the desired angle is reached.

3. While holding the removable footboard in place, tighten

the four (4) flat head screws and barrel nuts securely.

FIGURE 3 - ADJUSTING FLIP-UP

REMOVABLE FOOTBOARD

Removable

Footboard

Barrel Nut

Flat

Head

Screw

Angle Can Be Adjusted

Downward ONLY

FRONT

Footplate

Clamp

ADJUSTING FOOTBOARD ANGLE

5. Resecure the two (2) footboard pivots to the footboard

mounting brackets with the hex screws, spacers,

washers and locknuts. Refer to FIGURE 2 for the cor-

rect hardware orientation.

6. Torque the two (2) hex screws to 156in/lbs. and back

off the hex screws 1/8-1/4 of a revolution.

7. If necessary, reinstall the four (4) caplug caps.

PROCEDURE 3

F

R

O

N

T

R

I

G

G

I

N

G

S

FRONT RIGGINGS