Instruction Manual

IB-106-5081, Rev. 1.0

May 2005

3-2 Startup and Operation Rosemount Analytical Inc. A Division of Emerson Process Management

Model 5081FG

3-3 REESTABLISHING PROPER CALIBRATION

CHECK GAS FLOW RATE

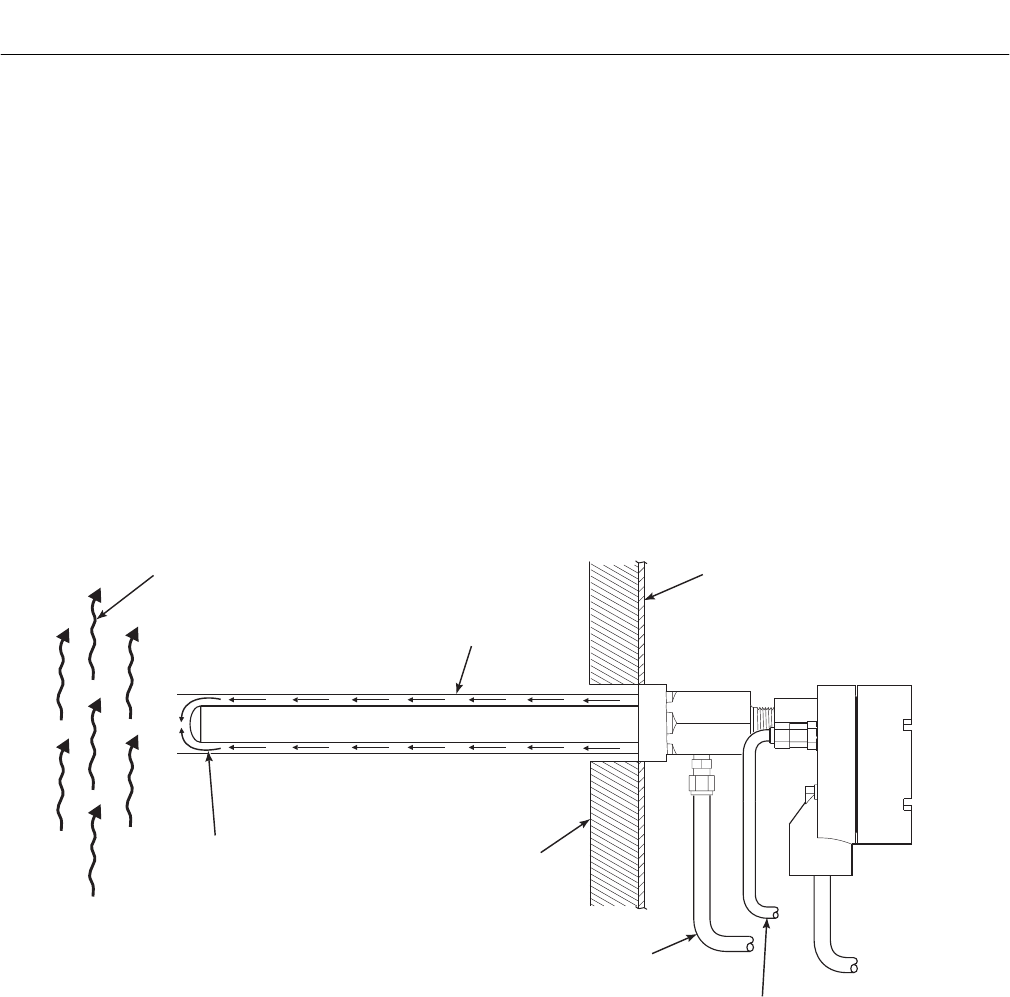

The calibration check gas flow must be enough

to ensure no combustion flue gases mix with the

calibration check gases and only clean, good

calibration check gas surrounds the cell without

expending excess gas (Figure 3-3). Monitor the

O

2

concentration using an IRC or HART Com-

municator. Set the calibration check gas flow

rate as follows:

NOTE

Only set the calibration check gas flow

rate at startup. It is not necessary to

perform this procedure for each cali-

bration check.

a. Adjust the calibration check gas flow to 5

scfh (2.5 L/min.) to ensure the cell is sur-

rounded by calibration check gas. Due to

the cooling effect of the gas, the cell tem-

perature will decrease slightly, causing the

O

2

concentration to drop. Once the elec-

tronics compensates for this effect, the O

2

concentration will stabilize.

b. Next, slowly reduce the calibration check

gas flow until the O

2

concentration changes,

which indicates that the calibration check

and flue gases are mixing. Increase the flow

rate until this effect is eliminated.

REFRACTORY

FLUE GAS

CELL

STACK OR DUCT

METAL WALL

PROTECTIVE

TUBE

CALIBRATION

GAS

CALIBRATION

CHECK GAS LINE

REFERENCE

AIR LINE

26020062

Figure 3-3. Proper Calibration Check Gas Flow Rate