Page 7

ak. DO NOT adjust or repair a hoist unless qualified to

perform hoist maintenance.

al. DO NOT attempt to lengthen the wire rope or repair

damaged wire rope.

am. DO NOT allow personnel not physically fit or properly

qualified to operate hoist.

an. DO NOT operate hoist unless limit switch is operating

properly.

ao. DO be sure there is no twist in wire rope.

ap. DO avoid operating hoist when hook is not centered

under hoist. Avoid side pulls and swinging of load or

load hook when traveling hoist.

aq. DO operate hoist within recommended duty cycle and

do not “jog’’ unnecessarily.

ar. DO conduct regular visual inspections for signs of

damage or wear.

as. DO NOT operate hoist with hooks that have opened

up. See Figure 5-1.

at. DO provide supporting structure or anchoring means

that has a load rating at least equal to that of the hoist.

au. DO NOT use hoists in locations that will not allow

operator movement to be free of the load.

av. DO, when starting to lift or pull, move the load a few

inches at which time the hoist should be checked for

proper load holding action. The operation shall be

continued only after the operator is assured that the hoist

is operating properly.

aw. DO NOT leave a loaded hoist unattended at the end

of a work shift or for extended periods during the work

shift. Where operations are such that this condition cannot

be avoided the operator must be assured that the

condition does not create a hazard to personnel or

property.

ax. DO NOT use the hoist load limiting device to measure

the load.

ay. DO NOT operate hoist unless hook moves in the same

direction as indicated on the pushbutton. If opposite

direction occurs, see pre-operation checks, Paragraph 2-

4.b.

az. Observe recommended inspection and maintenance

procedures.

ba. DO use common sense and best judgement whenever

operating a hoist. Observe American National Standard

Safety standard, ANSI B30.16, Iatest issue.

DO NOT operate hoist with the hoisting rope out of the

drum groves. Such operation may result in the rope

breaking and dropping the load which can cause

damage to equipment and injury to operator and other

personnel. Hoist rope will remain in the drum groves

during operation under normal operating conditions,

however, slack or kinked rope, excessive side pulls,

swinging or jerking of load, or similar abuse, may cause

the rope to leave the groves.

WARNING

SECTION IV — LUBRICATION

4-1.GENERAL. The lubrication services outlined in

paragraphs 4-2 thru 4-6 should be performed at regular

intervals to maintain top hoist performance and ensure long

life. Intervals of at least six (6) months, coinciding with spring

and fall seasons, are recommended. The reason for this is,

on hoists installed out-of-doors and in unheated areas, a

“cold test” lubricant is required in cold (below freezing)

climates making seasonal changes necessary.

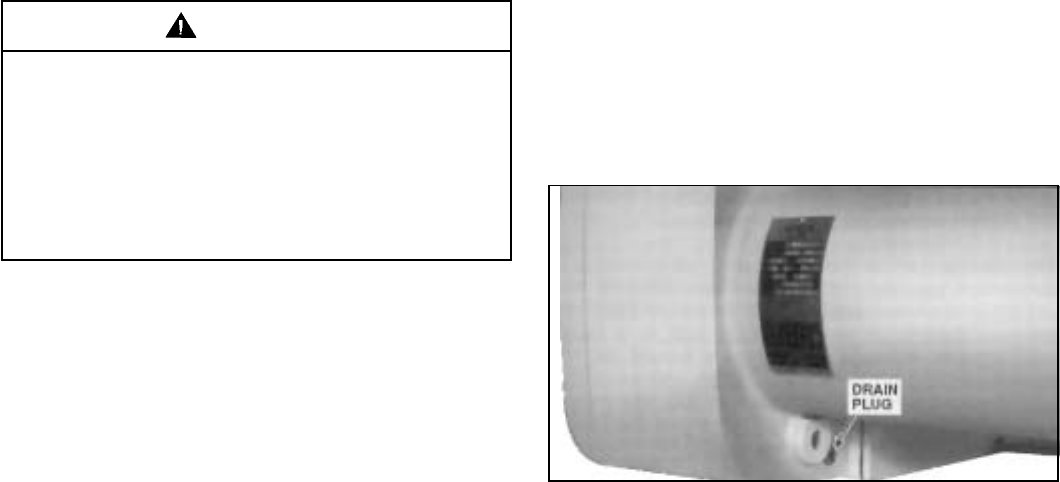

4-2. CHANGE GEARCASE OIL. (Figure 4-1)

a. Remove oil drain plug from bottom of gearcase and drain

out oil. (Two drain plugs, one on front and one on back of

gearcase.)

b. Flush out housing using petroleum solvent. Reinstall drain

plug.

c. Refill thru oil hole cover to proper level (bottom of oil

level plug hole) using 10 pints of Automatic Transmission

Fluid, DEXRON III Type, suitable for all temperature ranges.

Figure 4-1. View Showing Location of

One Oil Drain Plug.

4-3.LUBRICATE HOISTING CABLE. Hoists are shipped from

the factory without an exterior coating on hoisting cable. It is

recommended, where conditions permit, that the cable be

thoroughly coated at installation and kept well lubricated with

LUBRIPLATE Chain and Cable Fluid, or equal, suitable for all

temperature ranges.

4-4. LUBRICATE UPPER SHEAVE AND LOWER BLOCK

ASSEMBLY.

a. All hoists have grease fittings located in ends of sheave

pins. Apply (*) NLGI No. 2 grease for operating temperatures

from +50°F to +125°F. For colder temperatures, (-20°F to

+50°F) use NLGI No. 1 grease.

b. Apply a few drops of S.A.E. No. 50 oil to hook thrust

bearings.

(*) National Lubricating Grease Institute.

4-5. LUBRICATE LIMIT STOP LEVER.

a. Apply a few drops of S.A.E. No. 50 oil to pivot points of

limit rod.

b. Apply a few drops of S.A.E. No. 50 oil to shaft bearing at

rear of electrical compartment.

11413A