Page 21

SECTION Vll — ADJUSTMENTS

7-1. MECHANICAL LOAD BRAKE. The mechanical load

brake on Series 800 YALE hoists is a pawl and ratchet “Weston”

type automatic brake. The brake is not adjustable and requires

only periodic inspection and occasional replacement of the

friction washers.

7-2. MOTOR BRAKE. Instructions for adjusting the brake are

inside the brake cover and are repeated below. Check brake

adjustment after the first 30 days of service and regularly

thereafter during the six-month inspection procedure. Two

versions of the motor brake occur in this manual.

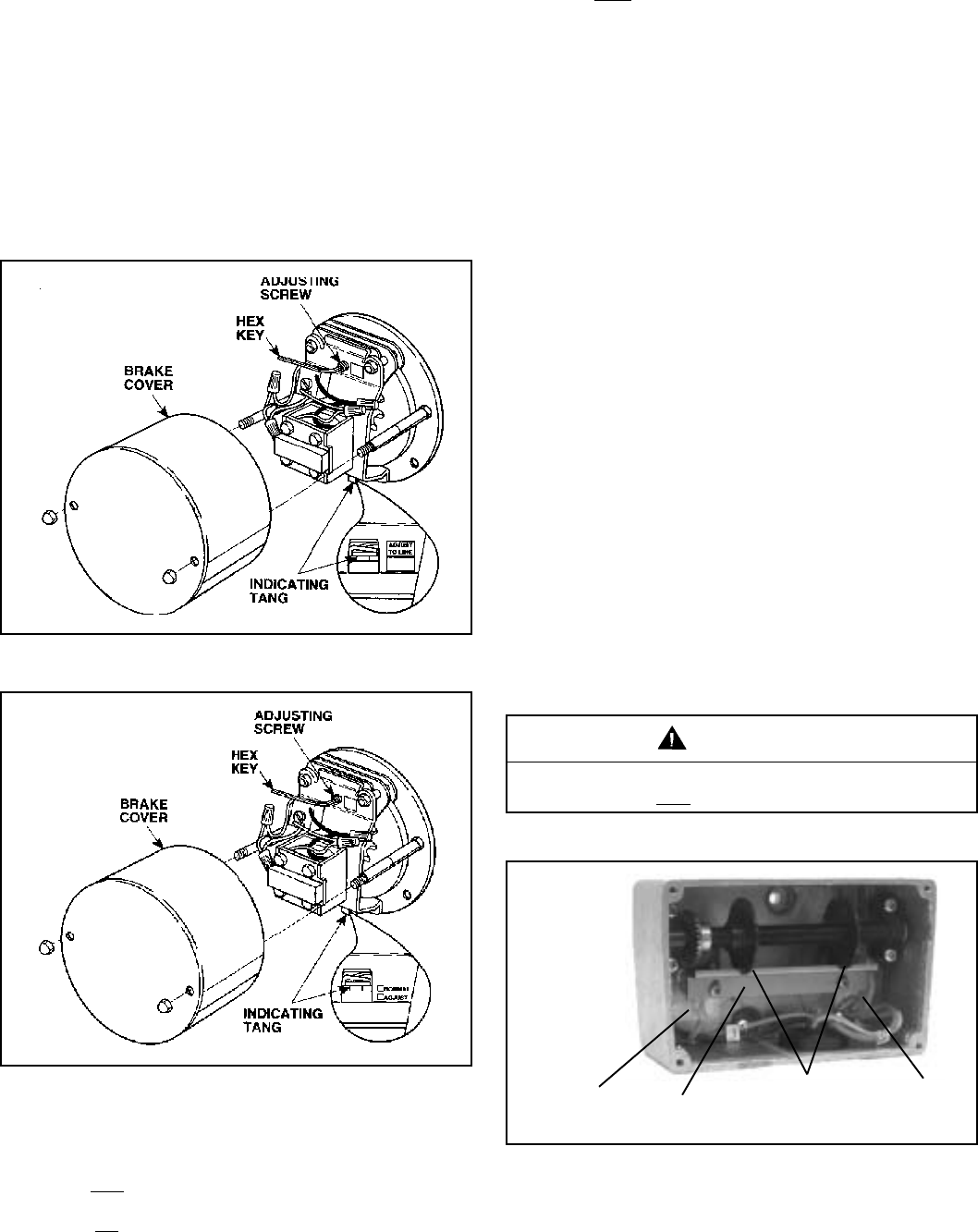

Figure 7-1A. Motor Brake - Later Version.

Figure 7-1. Motor Brake - Early Version.

a. Examine position of indicating tang located below the

solenoid coil (Figure 7-1 or 7-1A).

b. On the

later version of the brake (Figure 7-1A), if the tang

is below the line by more than 1/8", the brake should be adjusted

to bring the top of the tang back up alongside the line on the

adjust label.

c. On the early version of the brake (Figure 7-1), if the tang is

below the midway position of the two adjustment points shown

on the brake, the brake should be adjusted to bring the tang

back up alongside the NORMAL position on the brake.

d. Remove the hex key (1/8" size) from the holster on the

cover mounting stud and carefully turn the ADJUSTING SCREW

(located above the solenoid coil) clockwise. The indicating tang

will move a large distance for a small turn of the adjusting

screw, therefore turn the screw no more than one quarter turn

before checking adjustment.

e. After adjustment operate the brake by hand to assure brake

disc running clearance. The outboard brake pad should separate

from the brake disc by approximately .010".

f. Replace hex key in holster.

g Replace brake cover.

7-3. BLOCK OPERATED LIMIT SWITCH. The block operated

upper limit stop, furnished as standard equipment, is

nonadjustable and designed to stop lower block at its high

point of travel to guard against over-travel with possible damage

to hoist. When high point is reached, limit stop switch

automatically stops hook travel. If hook drifts upward slightly

after stop switch is actuated, a reversing switch will close and

automatically reverse direction of hook travel.

7-4. SCREW-TYPE LIMIT SWITCH. This limit switch has a

rotary screw driven by a gear reduction which is coupled to the

end of the drum shaft. Adjustment discs operate the contacts of

separate switches; one for the hoisting circuit and one for the

lowering circuit. The switch assembly must be wired in

accordance with the appropriate wiring diagram, which is

packaged with hoist. Adjustment of this screw-type limit switch

is accomplished as follows: (Refer to Figure 7-2).

Before attempting actual adjustments, be certain main

power switch is OFF and locked in the open position.

WARNING

Figure 7-2. Screw-Type Limit Switch Adjustment.

(Wires not Shown for Clarity.)

a. Remove four screws and lift off switch cover.

b. Loosen locking plate screws. Slide locking plate away from

adjustment discs.

12758B

LOCKING

PLATE

SWITCH

SWITCH

ADJUSTMENT

DISCS

12759

12759C