Page 5

(2) Temporarily connect hoist to power source.

(3) Operate á button briefly to determine direction of

hook travel.

(4) If hook raises, phase is correct. Turn power off and

make temporary connections permanent.

(5) If hook lowers, hoist is “Reverse Phased”. TURN

POWER OFF and correct by interchanging any two leads at

power source connection. Do not change internal wiring of

hoist.

c. Check Limit Switch Operation.

(1) A block operated upper limit stop (Figure 2-2) is

furnished as standard equipment. This limit stop is factory

set to stop lower block in its high position and guard against

over-travel and possible damage to hoist. (Note mounting

position of floating lever for 3 and 5 ton hoists.) No adjustment

can be made. Limit switch operation should be tested when

hoist is installed. Move hook to a low position by depressing

push button marked â. Now depress button marked

áá

áá

á to

raise hook. While hook is traveling upward, manually (or with

an extension pole) raise limit stop mechanism (Figure 2-2).

b.

Check Push Button Operation and Phasing.

On three phase hoists it is possible to have “Reverse

Phasing” causing the lower block to lower when the

áá

áá

á button is depressed. When this condition exists,

the automatic limit stop switch is inoperative and

hoist operation will be dangerous.

WARNING

If any push button binds or sticks in any position —

DO NOT TURN POWER ON — determine the cause

and correct the malfunction before operating.

WARNING

To properly check the phase of the hoist, follow the steps

below:

(1) With “POWER OFF” operate all the push buttons

and determine that they do not bind or stick in any position

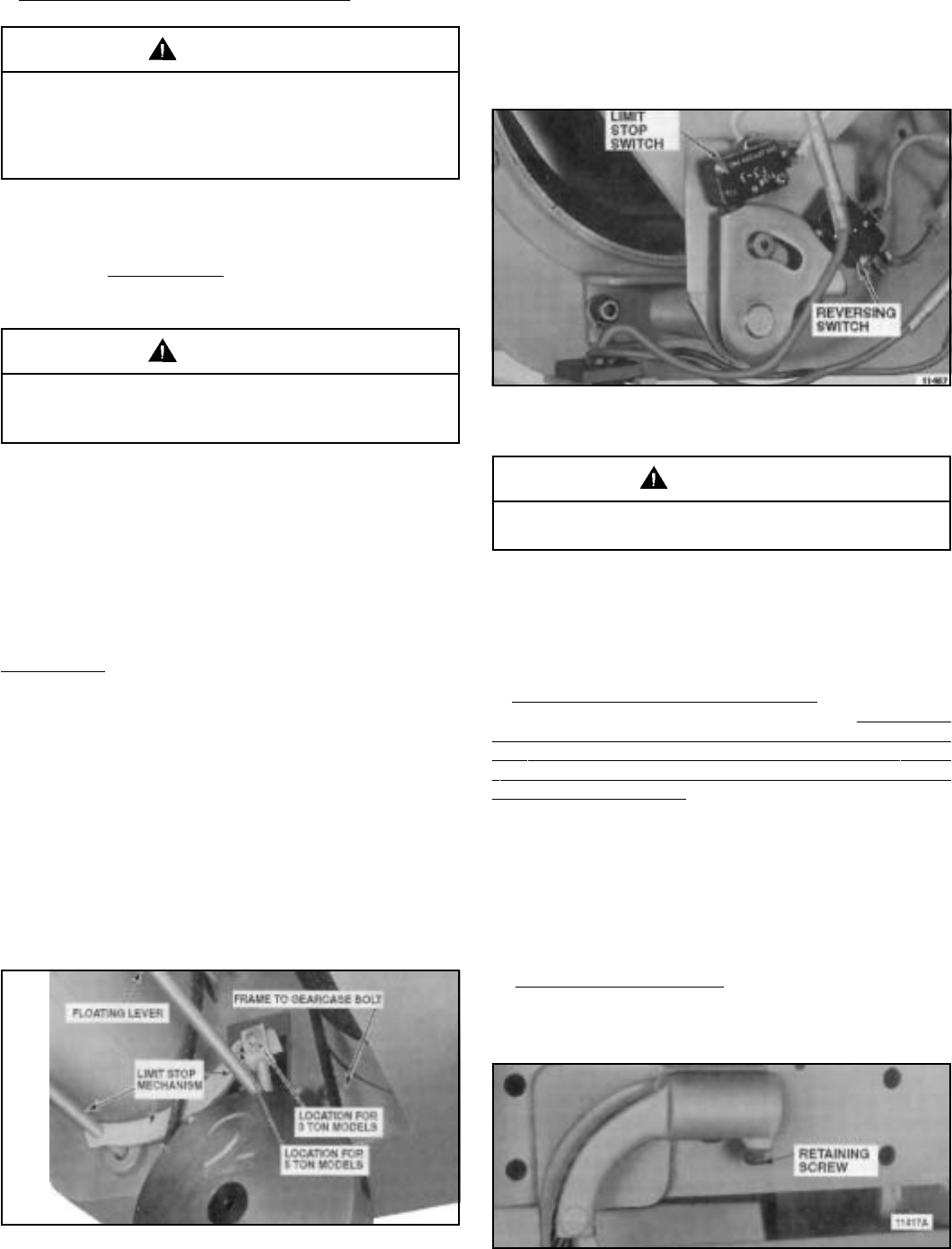

When floating rod is raised, stop switch is actuated first and

then the reversing switch is actuated (Figure 2-3). Stop switch

stops hoist. Reversing switch lowers hook block in case of

floating rod over-travel. If limit switch does not function in this

manner, refer to trouble shooting chart Section Vl for possible

remedy.

Figure 2-2. Limit Stop Mechanism

Being Tripped By Lower Block.

Figure 2-3. Electrical Compartment Cover Removed

Showing Limit Switch and Reversing Switch Arrangement.

Do not attempt to make above test with hook in a

high position near hoist.

WARNING

(2) A screw-type upper and lower limit switch is provided

optionally when both upper and lower limit stops are required

(Figure 7-2). This switch is adjustable and must be adjusted,

at time hoist is installed, to desired high and low limits of

lower block travel. Refer to Section Vll.

d. Check Lower Block and Hoisting Cable. Depress

ââ

ââ

â push

button and run lower block to its lowest position. No less than

two wraps shall remain on the drum with the loaded hook in

its lowest position, unless hoist is equipped with a lower limit

switch in which case no less than one and one half wraps

shall remain on the drum. Also check to see that lower block

and rope does not twist excessively. If it does twist to the

extent that two ropes rub against each other, disengage rope

from the frame anchor and twist rope four or five turns in a

direction opposite to that which the block turns. Reconnect

rope to anchor (Figure 2-4), holding firmly to eliminate rope

twisting back to its original position. Operate hoist up and

down a few times. If lower block still rotates, repeat process

until twisting is corrected.

e. Lubricate Hoisting Cable. For longer cable life, it is

recommended that the cable be lubricated at time of

installation by applying a Chain and Cable Fluid as outlined

in Section IV, paragraph 4-3.

Figure 2-4. Rope End Anchor.

11403