Page 4

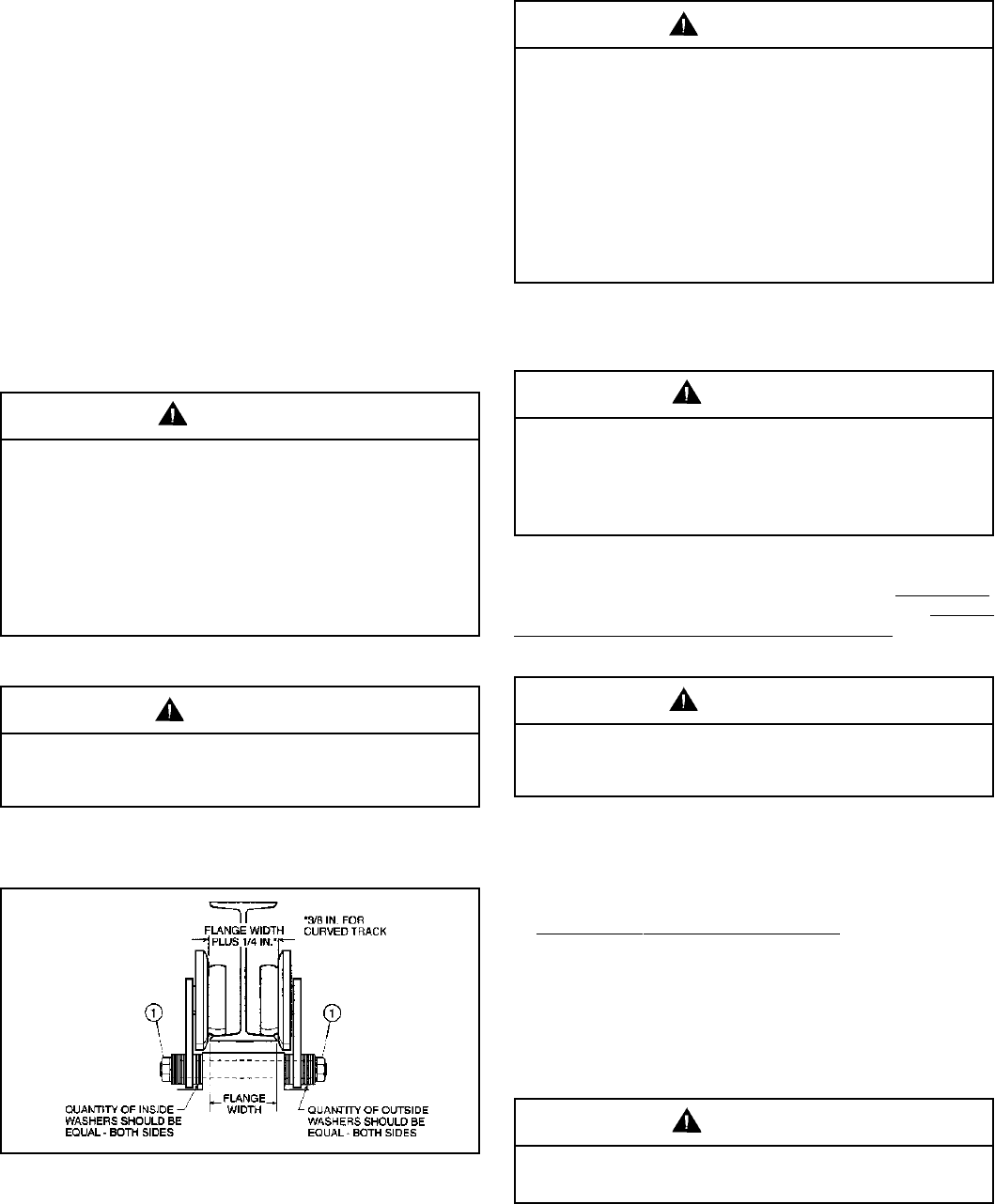

For trolleys which are to be mounted along the span of a

beam not having open ends, measure exact width of beam

flange and assemble trolley to hoist so that spacing between

wheel flanges is 1/4" (see Figure 2-1) greater than beam

width (3/8" if beam has curves). This is accomplished by

rearranging the spacer washers on the bolts connecting trolley

side plates to hoist mounting lug. If trolley is shipped separate

from hoist, see instruction sheets furnished with trolley for

orientation and installation.

When proper spacing has been determined, loosen mounting

nuts (item 1, Figure 2-1) to allow trolley wheels to spread far

enough to pass over edges of beam flange. (Some installations

may require complete removal of one trolley side plate.) Using

adequate equipment, carefully lift the hoist and trolley so the

wheel treads will rest on the lower beam flange. Replace side

plate and washers if removed for installation. Replace

suspension stud nuts.

Figure 2-1. Sectional View of Trolley showing proper wheel

and washer spacing.

2-3. CONNECTING HOIST TO ELECTRICAL SERVICE.

Electrical service to the hoist may be power cable or a guarded

system having sliding shoe collectors.

Recheck spacer washers to make certain that the number

of washers between the side plate and hoist suspension lug

are equal, and also the number on the outside of each side

plate are equal. The suspension stud nuts should only be

snugged up on the lockwashers until a load has been

applied on the hook. A partial load (approx. 25% rated hoist

load) placed on the hook will properly seat hoist in the

trolley. Tighten suspension stud nuts only after hoist has

been properly seated in the trolley.

CAUTION

a. Follow National, State and Local Electrical Codes

when providing electrical service to the hoist.

b. Make electrical connections using the appropriate wiring

diagrams furnished with the hoist. All electrical connections,

including connections to collectors or power cord, shall be

made only by qualified journeymen electricians.

c. When trolley is shipped separate from hoist, see special

instructions furnished with trolley for orientation and

installation.

2-4.PRE-OPERATION CHECKS.

a. Check Oil Level and Grease Fittings. The gearcase has

been filled with oil to the proper level and grease points for

lower and upper sheaves have been lubricated at the factory.

However, this should be checked before operating hoist. Check

oil level by removing oil level plug with hoist in a level position.

Oil level should be at the bottom edge of the plug hole. If not,

add oil as specified in Section IV. Grease fittings in lower and

upper sheave pins should show evidence of grease.

208/230/460V single speed motors are reconnectable at

the motor. See motor nameplate. Transformer may be

reconnected for 200/230/460/575V. See transformer. Check

with wiring diagram to make certain that motor, transformer

and brake leads are properly connected.

CAUTION

Be certain that electrical power supply is off and locked

in the open position before attempting any electrical

connections to the hoist. This equipment must be

effectively grounded according to the National Electric

Code, or other applicable codes. If the grounding

method used is through the trolley wheels, then each

section of track must be grounded by metal-to-metal

connection to the building ground. Certain

environments may prevent proper grounding by this

means. In this case a separate grounding conductor

should be provided.

WARNING

Mounting of the hoist-trolley unit on the monorail and

final pre-operation inspection shall be performed only

by qualified persons properly supervised.

WARNING

The green wire provided in the power supply cable

(when furnished) is a grounding wire and must be

connected to a proper ground.

WARNING

Overfilling of the gearcase may result in the excess fluid

being expelled through the breather.

CAUTION

11207A