Page 10

*

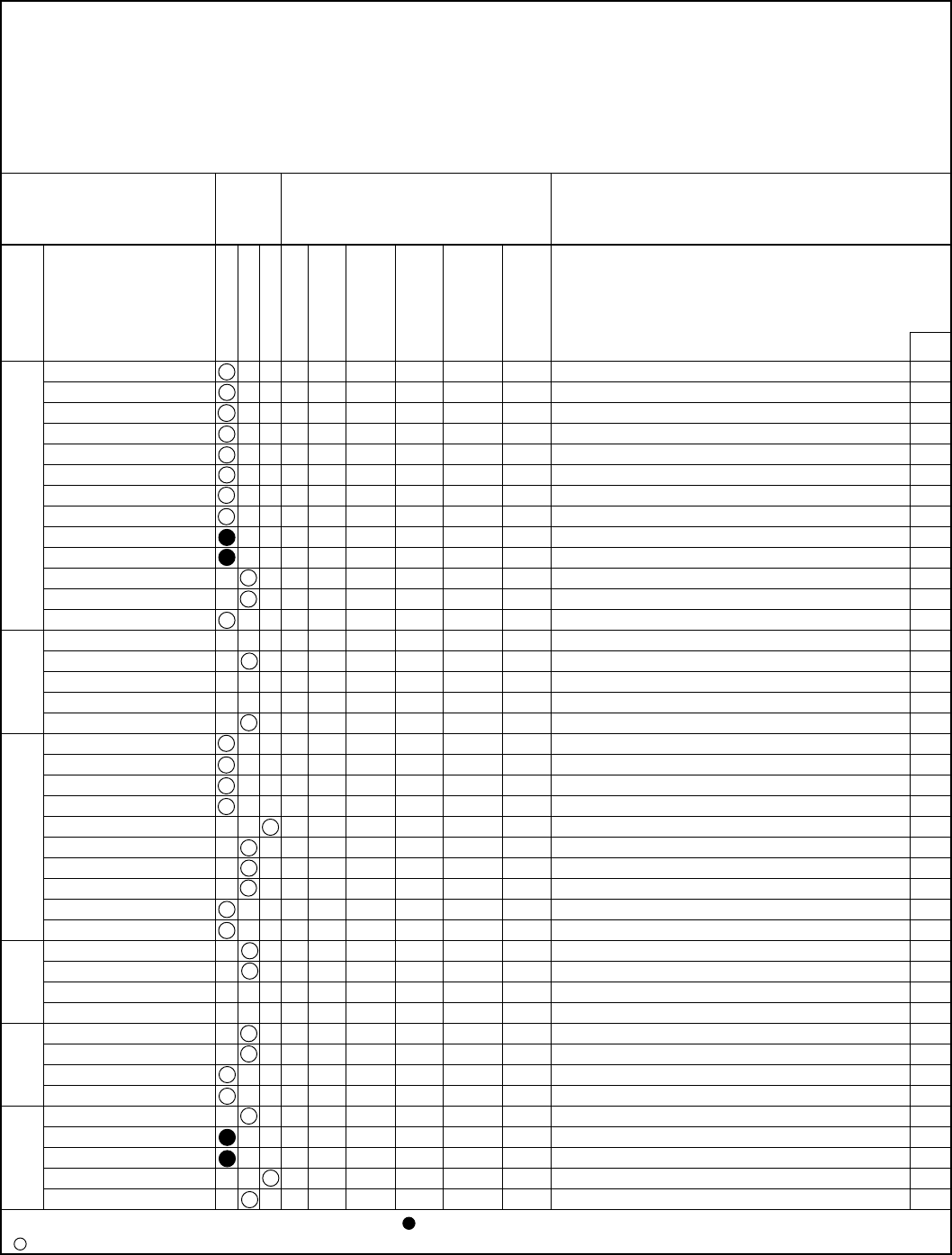

See text for DAILY & WEEKLY REQUIREMENTS.

SIGNED & DATED REPORT REQUIRED – OSHA.

INSPECTION INTERVAL.

X MAGNETIC PARTICLE OR EQUIVALENT EXAMINATION REQUIRED.

INSPECTION SCHEDULE AND MAINTENANCE REPORT

HOIST SERIAL NO. (MFGRS) _______________________ CUSTOMER CRANE IDENTITY NO. _______________________

RATED LOAD _________________ LOCATION IN PLANT __________________________________

TYPE ________________________ THIS INSPECTION IS MONTHLY o ANNUAL o

VOLTAGE _____________________ SEMI-ANNUAL o

INSPECTED BY: ________________ DATE _____________

*

Recom- CONDITION

COMPONENT, UNIT OR PART mended (Check column best indicating condition when CORRECTIVE ACTION

and location Inspection part or unit is inspected. Use note column to NOTES

Interval the right if condition is not listed below.)

COMPONENT,

UNIT OR

PA R T

(Indicate corrective action taken during inspection and note date. For corrective

action to be done after inspection, a designated person must determine that

the existing deficiency does not constitute a safety hazard before allowing

unit to operate. When corrective action is completed, describe and note date

in this column.)

Typical Inspection Schedule and Maintenance Report form.

User must adjust inspection interval and components to suit his individual conditions and usage. 12375B

MONTHLY

SEMI-ANNUAL

ANNUAL

GOOD

ADJUSTMENT

REQUIRED

REPAIR REQUIRED

(Loose Parts or

Wires)

REPLACEMENT

REQUIRED

(Worn or Damaged)

LUBRICATION

REQUIRED

(Low Oil or Grease,

Rust or Corrosion)

CLEANING OR

PAINTING

REQUIRED

HOIST LOCATION

TROLLEYRUNWAYS

RESISTORS

MISC.

DATE

Motor

Motor Brake

Mechanical Load Brake

Overload Clutch

Couplings

Gears, Shafts & Bearings

Upper Block

Lower Block

Hook & Throat Opening X Record Hook Throat Opening

Hoist Rope

Rope Drum

Guards

Limit Switch

Pushbutton

Wiring

Motor

Brake (when so equipped)

Couplings

Gears, Shafts & Bearings

Frame

Wheels

Bumpers

Guards

Conductors

Collectors

Hoist

Trolley

Monorail Joints

Monorail

Main Conductors

Main Collectors

General Condition

Load Attachment Chains

Rope Slings & Connections

Change Gearcase Lub.

Grounding Faults

CONTROL

STATION OR

PUSH BUTTON