Page 17

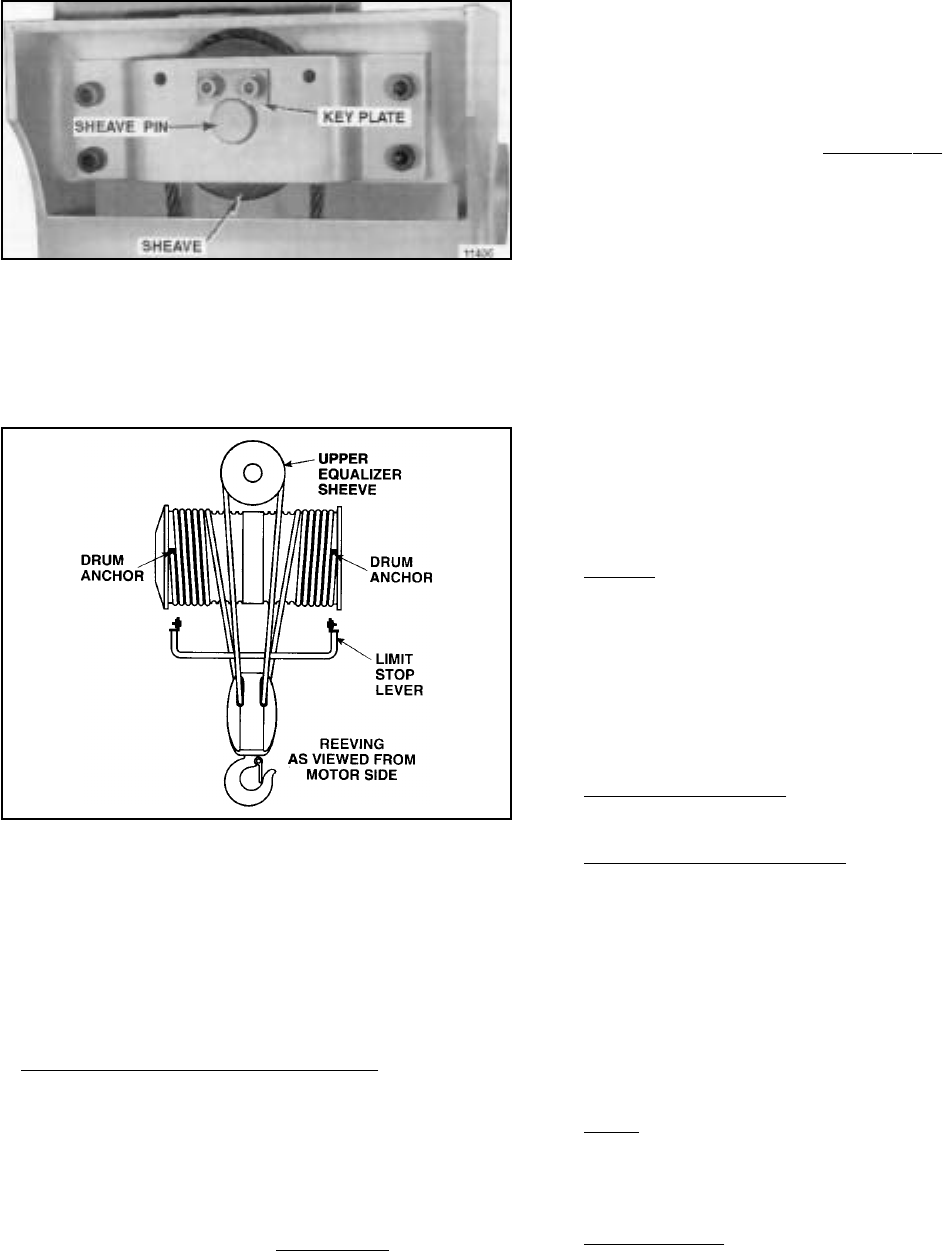

Figure 5-16. Upper Sheave Installed (Typical).

(3) Place sheave with rope into upper sheave pocket

and slide pin partially thru sheave. Install remaining washer

and push pin thru side plates. Install snap ring on each end

of pin to secure pin in place.

Figure 5-17. Hoist Reeving — Two Part Double.

(4) Insert lower sheave pin into bottom block removing

pipe as sheave pin is inserted. Be certain washers are

replaced as shown on parts illustration. With sheave pin

installed, replace key plates and bolts to secure sheave pin.

(5) Replace sheave guard.

(6) Lubricate rope per paragraph 4-3.

h. Checking for and removal of rope twisting.

Although rereeving of hoist may have been done carefully,

sometimes after new rope has been installed twisting may

occur. With new rope installed, the hoist block should be

raised and lowered several times with gradually increasing

loads, through full lift. If the block still rotates excessively at

no load, the rope may have twists which should be removed.

(1) To remove rope twist in single reeved hoists.

(a) Observe direction block tends to rotate.

(b) Lower the block to a low position and turn off

power.

(c) Rotate rope near the anchor end several turns in

a direction tending to correct block rotation. This

rotates rope end fitting in the anchor.

(d)Turn on power; raise and lower the block

several times to feed the correcting twist in the rope

through the reeving.

(e)If block still tends to twist, repeat the above

procedure until block rotation is corrected.

(2) To remove rope twist in

double reeved hoists.

(a) Observe direction block tends to rotate.

(b) Lower the bottom block unspooling rope from rope

drum until only one quarter (1/4) turn remains to

rope end anchors in drum.

(c) Rotate rope near ends entering drum in a direction

tending to correct block rotation. This rotates rope

end fittings in the drum.

(d) Turn on power; raise and lower the block several

times to feed the correcting twist in the rope through

the reeving.

(e)If block still tends to twist, repeat the above

procedure until block rotation is corrected.

5-10. TESTING HOIST AND OVERLOAD CLUTCH

(Optional).

a. General. Before placing hoist in service or after disas-

sembly and reassembly, hoist should be tested. To test sus-

pend hoist from an overhead supporting member of sufficient

strength to support the weight of the hoist and the rated load.

Hoists having overload clutches, require an overhead sup-

porting structure capable of supporting with appropriate safety

factor, a load equal to 200 percent rated load and the weight

of the hoist. Connect hoist to power supply as shown on hoist

nameplate and perform the checks listed in b and c below.

b. Check hoist as outlined in PRE-OPERATION CHECKS,

Section II, paragraph 2-4.

c.

Check hoist with capacity load.

(1) Attach rated load to lower hook.

(2) Depress

áá

áá

á push button and raise load. When push

button is released, hoist should immediately stop and hold

load at that level.

(3) Depress

ââ

ââ

â push button, lower load a short distance

and release button. Hoist should stop immediately and hold

load at that level.

NOTE: If load drifts downward slowly in step 2 or

3 above, motor brake requires adjustment — see

MOTOR BRAKE ADJUSTMENT — Section Vll —

paragraph 7-2.

d.

Overload Clutch. The overload clutch (optional) must

be tested for proper operation before placing hoist in service

or after disassembly and reassembly of hoist. For test

procedure follow instructions listed below.

12206A