Page 12

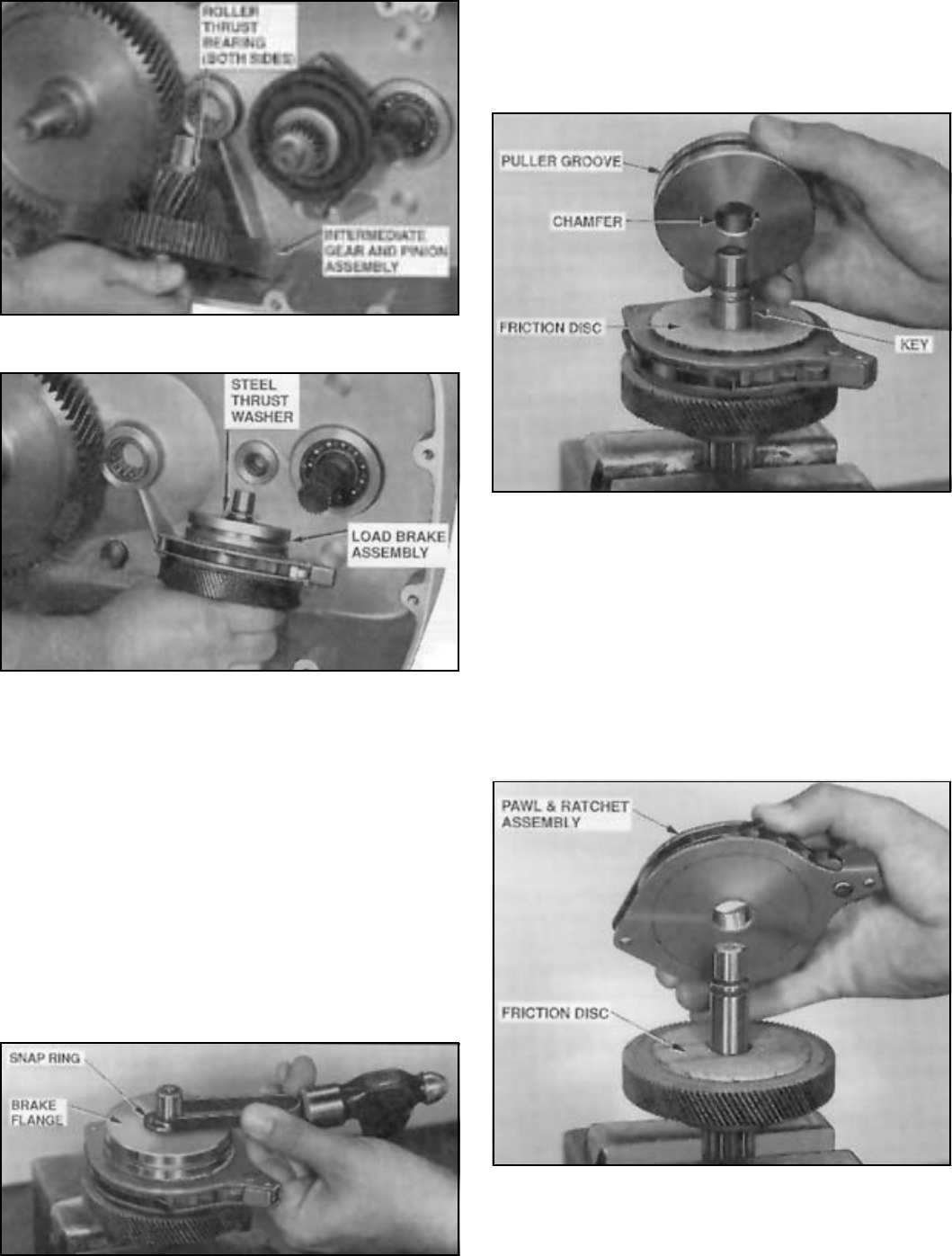

Figure 5-4. Removing Intermediate Gear and

Pinion Assembly.

Figure 5-5. Removed Load Brake Assembly.

d. To disassemble drum gear, remove external snap ring

from splined shaft, using heavy-duty snap ring pliers, and

pull off gear.

e. To disassemble intermediate gear and pinion, press

pinion shaft from gear using an arbor press.

f. It is recommended that load brake assembly be returned

to an Authorized Repair Station for inspection and repair. If it

is necessary that you make your own inspection and repair,

instructions below must be followed:

(1) Place load brake assembly, flange up, in a vise

equipped with brass or copper jaw plates to protect pinion

gear teeth. Remove snap ring from end of load brake shaft

(Figure 5-6).

Figure 5-6. Remove Snap Ring From Load Brake Shaft.

10333

(2) Using a puller tool, remove brake flange from shaft.

A groove is provided around outer diameter for this purpose.

See Figure 5-7. Remove key from shaft and lift off 2 friction

discs, and the pawl and ratchet assembly (Figure 5-8).

Figure 5-7. View Showing Load Brake

Flange Removed.

(3) Remove load brake gear. If replacement of spring,

spring retainer or cam is necessary, press off shaft (Figure

5-9).

(4) The load brake pawl and ratchet is a riveted

assembly and is not to be disassembled.

(5) Clean all parts thoroughly and inspect for wear and

damage. Replace all parts that are excessively worn or

damaged. Hard surface or glazed friction discs should be

replaced.

Figure 5-8. Removing Pawl and Ratchet Assembly

From Load Brake Shaft.

g. Reassemble gearing and load brake parts following

reverse procedure of disassembly. In assembling load brake,

observe assembly steps (1) through (4) below:

11422

11421

10334

10335A