- 17 -

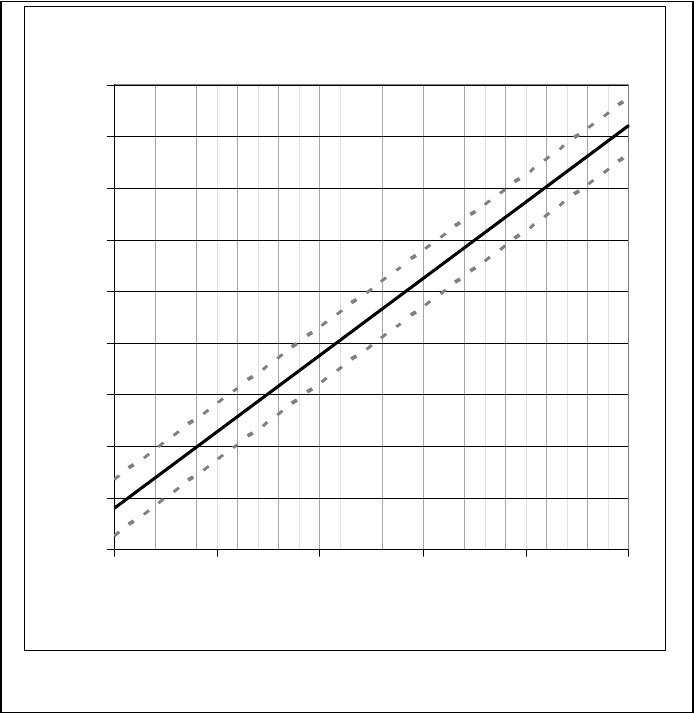

The gas properties which form

the basis for the flow

measurement, such as viscosity

and specific heat, exhibit a

slight dependence on the gas

pressure. Fortunately, this

pressure dependence is

predictable and can be

corrected for in cases where it

has an impact on accuracy

(typically only significant for

pressures in excess of 100

psig). The graph shown in

Figure 3-1 shows the expected

span shift as a function of

pressure for nitrogen. This

behavior is similar for most

diatomic gases (O

2

, H

2,

etc),

whereas this effect is

insignificant for the monatomic

gases (He, Ar, etc). This span

shift must be considered and

accounted for as appropriate

for accurate flow

measurements at high pressure

conditions.

3.6. Warnings/Alarms

There are two alarm contacts

on the terminal strip connector within the electronics enclosure (See Section 2.8). These

function as isolated semiconductor switches sharing a single, isolated common line. In its

normal state each switch is “open”; when an alarm is activated the switch is “closed”.

The meter’s processor can be configured via the digital interface to establish the internal

condition for activating each alarm. There are many choices for internal alarms and warnings

including overflow, underflow, or various instrument error conditions. Each alarm can also be

given a selectable “wait time”—a period for which it must remain in the alarm condition before

the physical alarm is activated. See the Software Manual for detailed alarm setting and

configuration information.

3.7. Multi-gas Calibrations

The Hastings 400 Series flow meters can have up to eight different calibrations stored

internally. These are referred to as gas records. These records are typically used to represent

different gases, but they can also be useful in other ways; for instance reporting the flow in an

alternate range, flow unit or reference temperature. The records are referred to by their

number label from #0 – #7. The first six records are, by default, setup for the same range in the

most common six gases as shown in Figure 2-11. If a gas other than one of these six is specified

on the customer order it will be placed in record #6. If a second different gas is selected, it

will be placed in record #7. If multiple different gases or ranges are specified they will replace

some of the standard six gases. Only the gas(es) specified on the order will be verified. The

other records will use nominal gas factors to approximate the gas sensitivity until an actual

calibration is performed to correct for individual instrument variations. Selecting the active gas

record can be done in one of two ways—a hardware setting or a software setting. The hardware

setting is done by accessing a rotary encoder on the upper PC board in the electronics

enclosure. When set to a number position from 0 to 7 it activates the corresponding gas record.

When set to a number greater than 7, the gas record control is passed to software. If the

software setting mode is enabled, then the “S6” digital command can be used to set the active

gas record as shown in the example below.

Figure 3-1 The pressure effect on flow calibration (for nitrogen)

Pressure Effect

-1

0

1

2

3

4

5

6

7

8

0 200 400 600 800 1000

Line Pressure (psig)

Span Shift (% Reading)