12 Daniel 3812 Liquid Ultrasonic Flow meter design

Section 1: Introduction Daniel 3812 Liquid Ultrasonic Flow Meter Installation Manual

May 2015 3-9000-765 Rev H

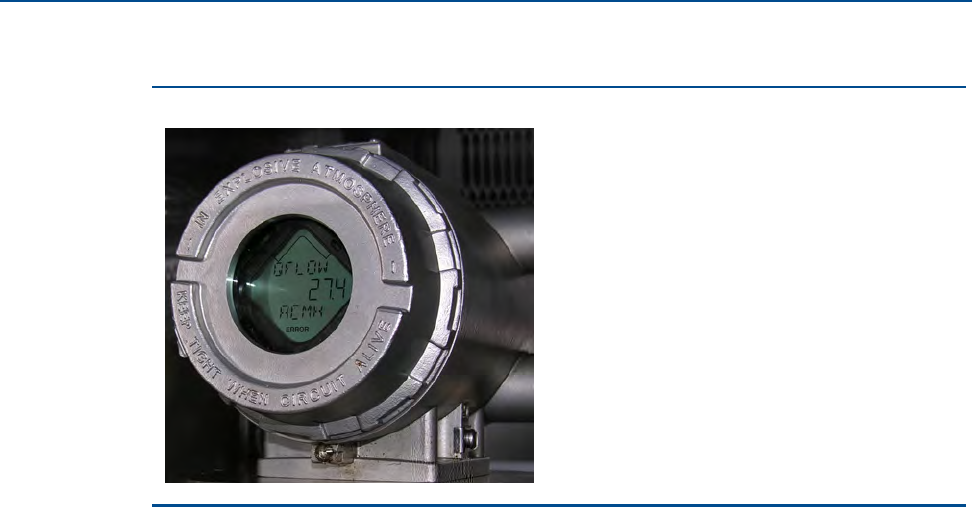

Figure 1-8 Optional local display and glass endcap

The Daniel 3812 Liquid Ultrasonic Flow Meter is a two-path (four transducers) in-line meter

designed to measure the difference in signal transit time with and against the flow across one or

more measurement path(s). A signal transmitted in the flow direction travels faster than one

transmitted against the flow direction. Each measurement path is defined by a transducer pair

in which each transducer alternately acts as transmitter and receiver. The meter uses transit

time measurements and transducer location information to calculate the mean velocity.

Computer simulations of various velocity profiles demonstrate that multiple measurement

p

a

ths provide an optimum solution for measuring asymmetric flow. The Daniel 3812 Liquid

Ultrasonic Flow Meter utilizes two cross-bore, parallel-plane measurement paths, offers a high

degree of repeatability, bi-directional measurement and superior low-flow capabilities without

the compromises associated with conventional technologies.

The Daniel 3812 Liquid Ultrasonic Flow Meter’s U.L. safety listing is accomplished through the

c

o

mbination of an explosion-proof Transmitter Electronics Enclosure that houses the CPU

Module, Power Supply board, I.S. Barrier board, Backplane board and optional LCD Display

board.

NOTE: The op

tion

al LCD Display requires firmware v1.04 and Uboot version, January 31, 2013.

The Base Electronics Enclosure is intrinsically safe and houses the Acquisition Module, the

ac

quisition cable and wiring. The Intrinsically safe transducers and cable assemblies are

designed for Class 1, Division 1, Groups C and D areas without need of further protection when

installed in accordance with the field wiring diagram (refer to Daniel drawing DMC - 004936, see

Appendix A and Section 1.8).