26

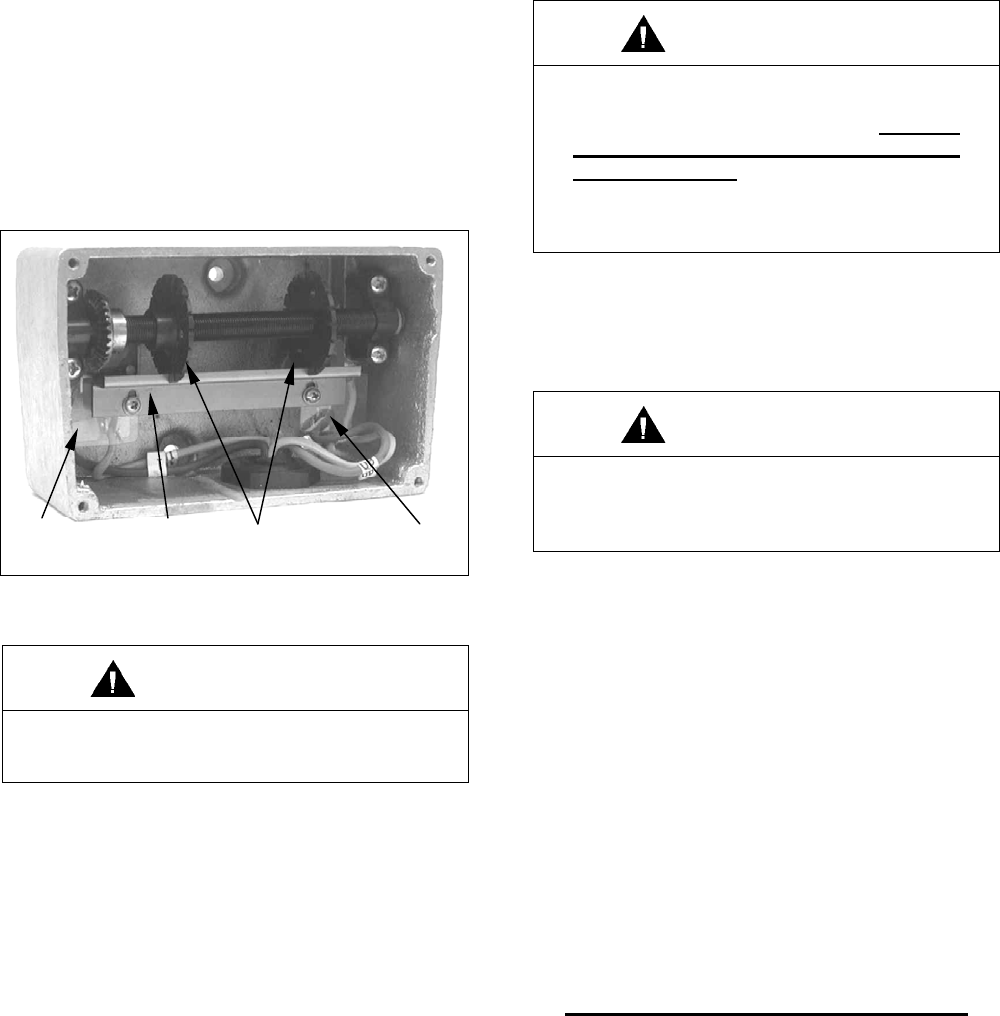

This limit switch has a rotary screw driven by a gear

reduction that is coupled to the end of the drum

shaft. Adjustment discs operate the contacts of

separate switches, one for the hoisting circuit and

one for the lowering circuit. The switch assembly

must be wired in accordance with the appropriate

wiring diagram, which is shipped with the hoist.

Instructions for adjusting limit switch are inside

cover and are repeated below (see Figure 7-2).

SWITCH LOCKING ADJUSTMENT SWITCH

PLATE DISC

Figure 7-2. Screw-Type Limit Switch Adjustment

(Wires Not Shown For Clarity.)

WARNING

Be certain that electrical power supply

is OFF and locked in the open position

before removing limit switch cover.

a) Remove four screws and lift off switch

cover.

b) Loosen locking plate screws. Slide locking

plate away from adjustment disc.

c) Turn proper adjustment disc (right for up,

left for down) toward switch to reduce hook

travel or away from switch to increase hook

travel.

d) Slide locking plate back into position

ensuring slots on adjustment discs are fully

engaged, tighten locking plate screws to 4

in-lbs.

e) Replace cover.

f) Carefully check limit switch operation

without load before placing hoist in service.

If misadjusted, repeat steps above. Allow 3”

for hook drift in both directions. Never allow

less than two (2) complete wraps of rope

on drum with hook in lowest position.

WARNING

Check limit switch operation carefully,

without load, before placing hoist in

service. If misadjusted, SEVERE

DAMAGE AND/OR A DROPPED LOAD

COULD RESULT. Allow 3” for hook drift

in both directions. Never allow less than

two (2) complete wraps of rope on drum

with hook in lowest position.

Provide a light film of MPG grease (Paragraph 4-7)

on gear of both limit switches.

7-4. SHORTENING OF PUSHBUTTON CABLE.

WARNING

Be certain that electrical power supply

is OFF and locked in the open position

before attempting shortening of push

button cable.

a) Loosen screws at cable connectors and

clamps at top of cable.

b) Adjust steel support cable to proper length

and tighten screws.

c) Loosen upper cable grip and pull excess

cable into connection box at hoist.

d) Tighten cable grip and cut off excess cable.

e) Strip cable sheath and connect wires with

the same type of terminals previously

furnished (care must be taken to match

previous wire color coding with wire

markers in accordance with wiring diagram

furnished with hoist.)

SECTION VIII – WIRING DIAGRAMS

8-1. GENERAL. Comprehensive wiring diagrams for

Yale electric hoists have been omitted from this

book because of the many possible variations. This

is due to different currents and types of electrical

components used in their construction. Figures 8-1

and 8-2 are examples of typical two-speed hoist

and trolley wiring diagrams respectively. However,

please consult the exact wiring diagrams for your

hoist. A print of the correct wiring diagram for each

hoist is furnished as a separate insert and shipped

with the hoist. We suggest you carefully file the

wiring diagram with this book for future reference.