22

(3) Connect the brake leads to the terminal

block on the brake body.

(4) Install the forward fan mounting retaining

ring and install the fan. Install the rear

retaining ring. Install the fan shroud and

bolts.

(5) Test hoist per Section V, Paragraph 5-13.

5-11. INSPECTION OF HOIST TRAVERSE

DRIVE.

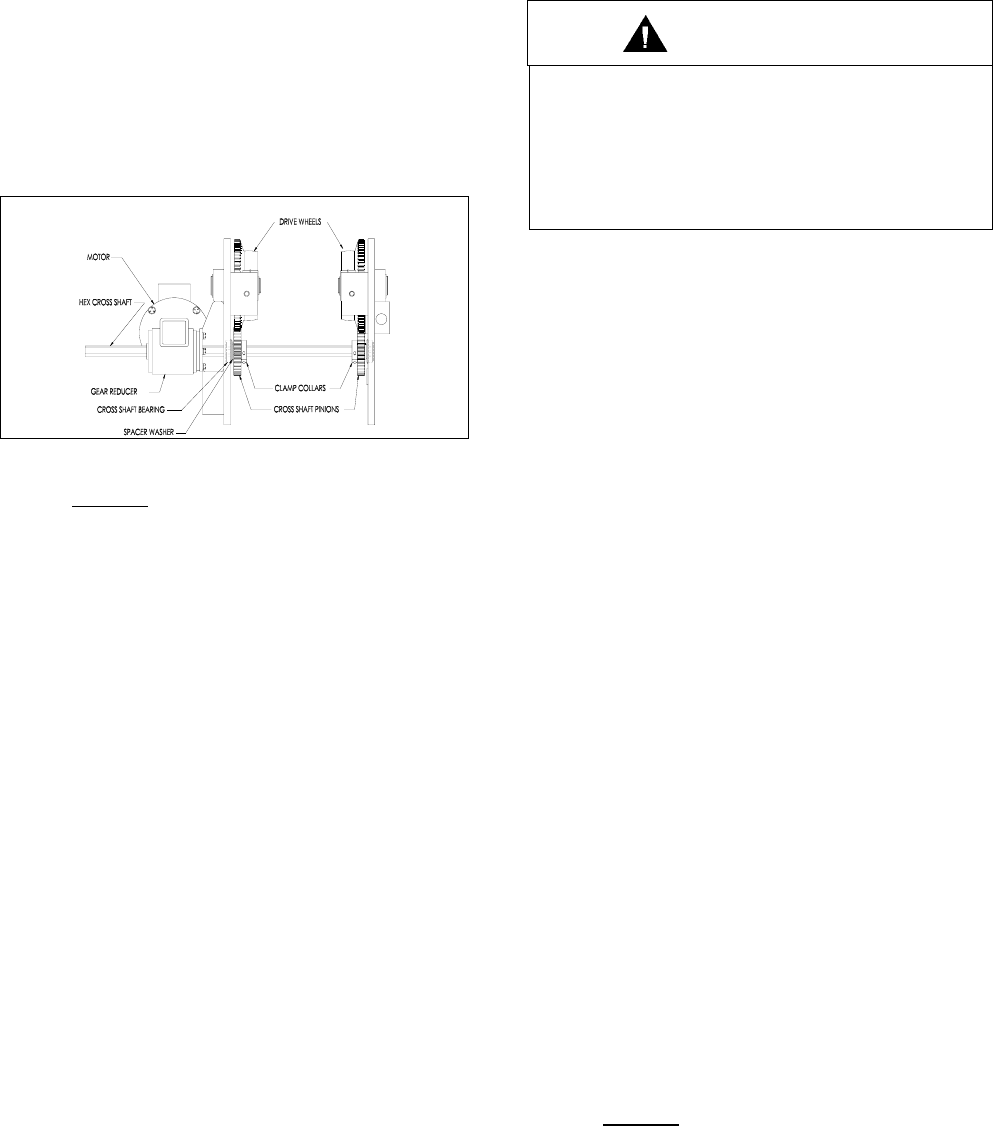

Figure 5-10. Traverse Drive Arrangement.

a) General.

The traverse drive consists of four

single flange wheels, two on each side of

the beam, carried directly by the hoist

frame. These wheels rotate on sealed ball

bearings supported by fixed pins. Pinions

drive two opposing wheels with gear teeth

cut into the flange. Both pinions are

mounted on a hexagonal drive shaft

supported by sealed ball bearings at each

hoist side. The pinions are held in place by

means of clamp collars. The drive shaft

passes through one hoist side and is driven

by a single reduction hollow shaft gear

reducer.

b) Ensure that the hoist is properly fitted to the

beam. The hoist must be centered on the

beam with clearance between the sides of

the bottom of the beam flange and the

inside faces of the wheel flanges. Proper

clearance must exist along the entire length

of beam that the hoist can traverse. An

amount of 3/32 to 1/8 inch clearance per

side is recommended for a total of 3/16 to

1/4 inch wider than the beam flange. If too

little or too much clearance is determined,

adjust trolley per Section II, Paragraph 2-2.

c) Inspect wheel treads, flanges, and gear

teeth for wear. Check for adequate

lubrication (WG, Section IV, Paragraph 4-7)

on the wheel gear and pinion mesh. Check

wheel bearings for any signs of wear,

including rough rotation and signs of

lubricant leakage. Replace all damaged or

missing items. Wheels must always be

changed in opposing pairs and drive

wheels should be changed when the drive

pinions are replaced.

CAUTION

Ensure that the cross shaft is properly

positioned and locked into place by

means of the clamp collars. Failure to

do so may allow the drive shaft to

contact the rope on the rope drum (B

frame) or the hoist gearcase (C frame

hoist).

d) Examine the drive pinions, cross shaft, and

cross shaft bearings. Check pinions for

gear tooth wear and proper alignment with

wheel gear. A spacer washer between the

cross shaft bearings and the pinion aligns

the gear mesh. Clamp collars hold the

pinions and spacer washers tight against

the bearings. Verify that the clamp collars

are tight on the cross shaft. If it is

necessary to adjust or reset the clamp

collars, verify that the hex shaft surface is

free of mechanical damage and oil before

tightening the clamp collars. Drive pinions

must be replaced as sets and should be

replaced along with the drive wheels. The

cross shaft bearings are sealed for life and

should be replaced at any sign of

mechanical wear or lubricant leakage.

e) Inspect the traverse gearbox and motor.

Look for signs of rough operation,

mechanical damage or lubricant leaks.

Inspect the hollow bore and hexagonal

drive shaft for wear. Verify that the four

bolts that hold the gearbox to the trolley

frame and the four bolts that hold traverse

motor to the gearbox are all present and

tight. Replace and tighten as necessary.

The factory recommends complete

replacement of the traverse gearbox.

However, gearbox service may be

available from you local authorized Yale

repair center.

5-12. TESTING BLOCK OPERATED LIMIT

SWITCH.

a) General.

The block operated limit switch is

a secondary upper limit switch actuated

when the lower block contacts the limit

switch weight. The rotary geared limit

switch (screw type limit switch) is the

primary upper limit switch and must be

temporarily disconnected to allow the block

operated limit switch to be tested.