17

CAUTION

It is imperative that rope reel or coil

rotates as rope unwinds. If coil or reel

does not rotate the wire will be twisted

as it is uncoiled and kinking will result.

A kinked rope may be damaged and

unsafe for maximum service.

b) Before removing the old rope, refer to

reeving diagram, Figure 5-6. To assist with

re-reeving your hoist, refer to the reeving

diagram and corresponding paragraph that

describes the reeving procedure.

c) Removing old rope

. Please, refer to the

Section IX Parts lists to assist in locating

components referred to in the following

paragraphs.

(1) Lower the lower block to a scaffold 6 to 7

feet below hoist to relieve tension on wire

rope. (Lower block may be lowered to the

floor if desired; however, to handle less

weight and for ease of reeving, adequate

scaffold below the hoist is

recommended.)

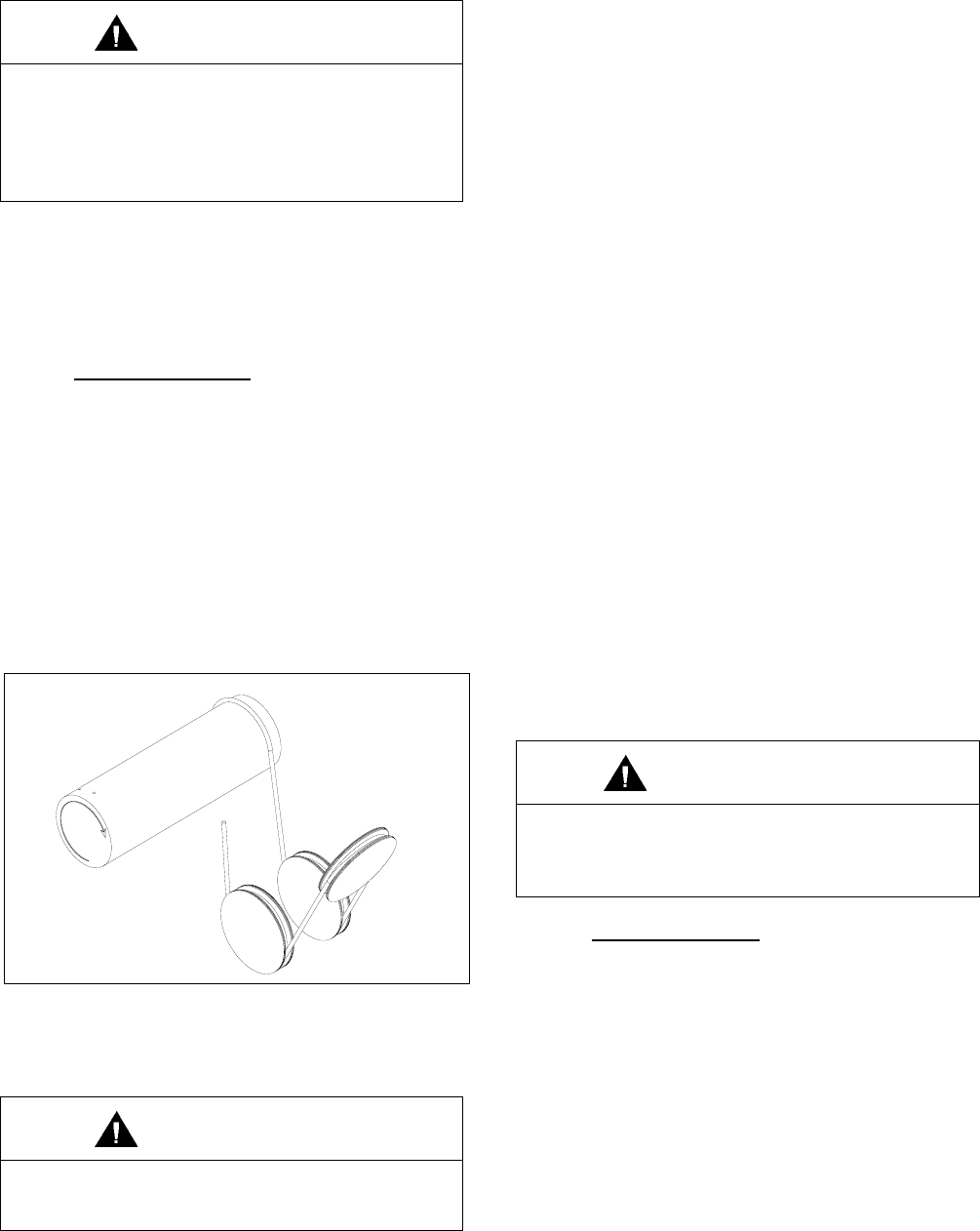

FIGURE 5-6. Reeving Diagram – 4 Part

Single-Reeved. (Note: Arrow on Drum

Indicates Direction of Drum when

Lowering.)

CAUTION

Be certain all personnel are clear of

hoist as components, hardware, and

wire rope are removed from hoist.

(2) Remove block operated limit switch

weight from rope.

(3) Remove retaining rings from lower block

sheave pin.

(4) Remove outer lower block sheave

covers.

(5) Remove lower block sheaves and wire

rope.

(6) Remove two (2) rope retention bolts and

nuts from upper block yoke.

(7) Remove two (2) bolts and key plate to

allow removal of upper block sheave pin.

(8) Securely grasp the upper block sheave

before carefully sliding the sheave pin

out. Note that two spacers will also be

released as the pin is removed.

(9) Remove wire rope from sheave.

(10) Remove retaining rings or cotter pins

from dead end anchor pin. Securely

grasp the swaged wire rope and, in some

cases, spacers before removing the pin.

(11) Remove Rope Guide.

(12) Make certain all personnel are clear of

hoist and operate hoist “DOWN” to

completely unwind all wire rope from

drum. Stop hoist so all (3) rope clamps

are accessible. Remove rope clamps and

wire rope from drum.

WARNING

Winding rope on rope drums with power

can be hazardous. Keep hands safe

distance from drum; wear gloves and

use extreme care when winding rope.

d) Installing new rope.

(1) Thread rope to drum from trolley frame

side then secure with rope clamps as

follows:

(a) Make sure that the rope clamp

groove size utilized as marked

directly above the groove matches

the rope size for your hoist (7/16” on

the “B” Frame and 9/16” on the “C”

Frame).

(b) With the rope lying in the bottom of

the drum groove, begin tightening the

rope clamp at the tail end of the rope.

Torque to 50 ft-lbs.

(c) With tension on the rope keeping it

properly seated in the drum groove,