20

(4) Disconnect the wiring and conduit from

the motor junction box.

(5) Provide a means to support the hoist

motor. The hoist motor weighs approx-

imately 250 lbs. And must be held level

while removing and installing.

(6) Once the motor is properly supported,

remove the hardware fastening it to the

gear case. Carefully withdraw the motor

horizontally straight out from the gear

case. Do not tip or move the motor from

side to side.

(7) Replace the motor shaft seal using an

appropriate seal driver. It is

recommended that a new seal be

installed each time the motor is removed

from the case.

IMPORTANT!

(8) Before installing the motor, pack the gear

teeth with MPG grease (Paragraph 4-7)

and wrap the gear teeth with a number of

layers of Teflon tape to protect the seal

lip from being damaged by the gear

teeth. Coat the seal lip and the motor

shaft with MPG grease.

NOTICE

Failure to use a factory replacement seal

will cause premature seal failure due to

specific lip material requirements that

must be met.

(9) Install the motor to the gear case. The

motor shaft must be in line with the seal

bore and perpendicular to the mounting

surface before attempting to insert the

shaft through the seal. The motor shaft

must remain horizontal and not rock up

and down or side-to-side while installing

the motor or seal damage will occur. It

may be necessary to rotate the rope

drum slightly to align the gear teeth to

mesh with the teeth on the motor shaft.

Ensure that the motor seats properly into

the rabbet fit machined in the gear case.

Fasten the motor to the gear case.

(10) Reconnect the conduit and power

leads to the motor. See Section VIII

and refer to the specific wiring

diagrams shipped with your hoist.

(11) Refill gear case with lubricant per

Section IV, Paragraph 4-2.

(12) Test hoist to ensure proper operation

per Section V, Paragraph 5-13.

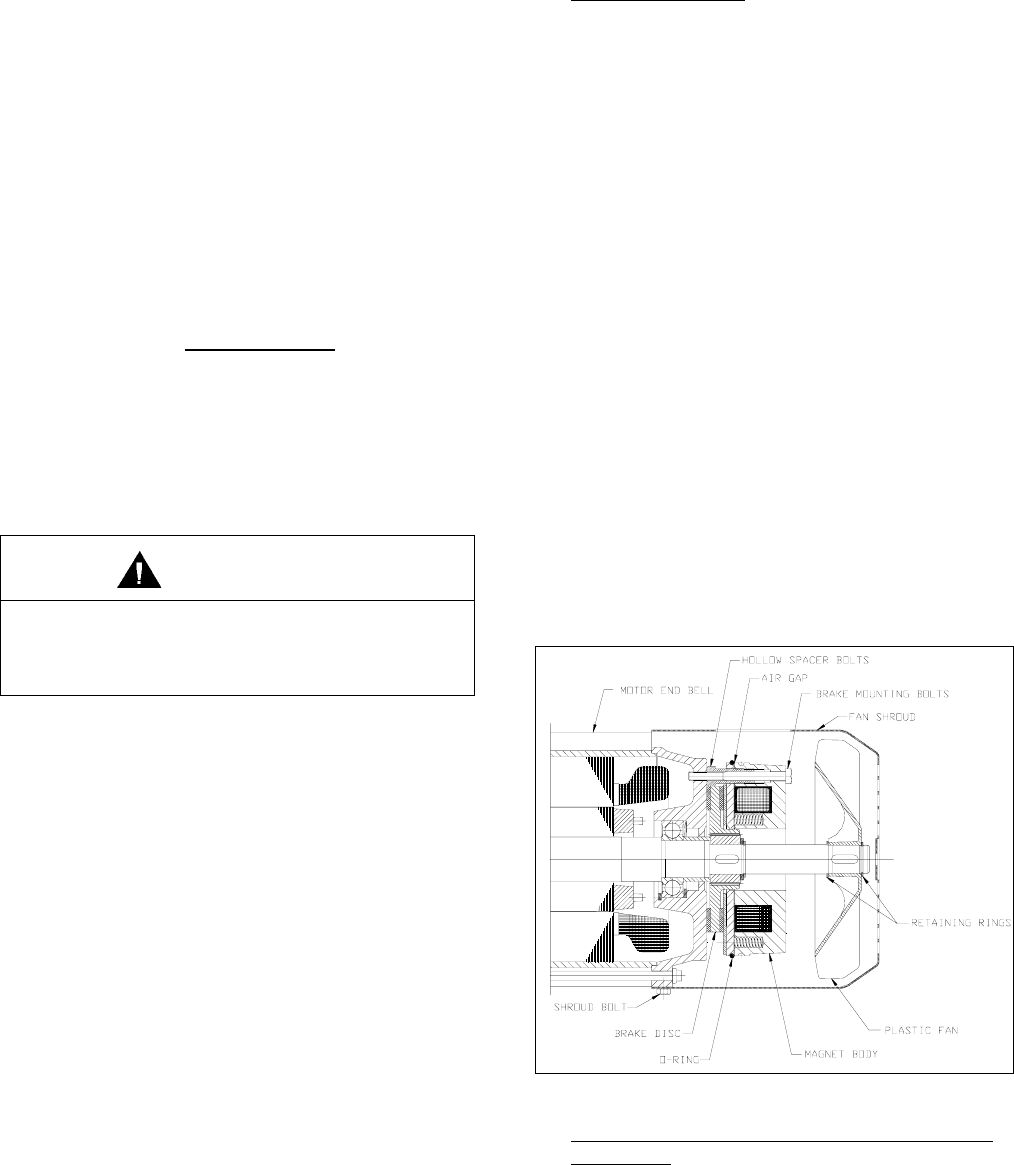

5-10. INSPECTION OF MOTOR BRAKE AND

ACTUATING MECHANISM.

a) General Operation

. The hoist brake is an

electro-magnetically released, spring set non-

adjustable brake. Torque is generated by

compressing a friction disk between the

stationary motor end bell and the spring loaded

brake armature. The friction disk is fixed to the

motor shaft and rotates with the motor shaft.

When the magnet coil is energized, the

armature plate is pulled across the air gap. The

friction disk is carried by a splined hub that

permits axial movement when the brake is

released. This axial movement releases both

sides of the friction disk from their mating

stationary surfaces and allows the friction disk

to rotate freely when the brake is energized.

When power is removed from the magnetic

coil, the compression springs push the

armature against the friction disk and the other

side of the friction disk against the motor end

bell generating the torque necessary to stop

the hoist machinery and hold the load.

It will be necessary to compensate for the

friction disk wear when a greater amount of

hook movement (drift) is noticed when

stopping. There is no torque adjustment of the

brake. Friction disk wear can only be

compensated for by resetting air gap.

Figure 5-9. Motor Brake.

b) Friction Disk Inspection and Air Gap

Adjustment.

(1) Lower hook block to the floor and relieve

all load from ropes.