14

WARNING

Do not operate a hoist having unusual

vibrations, sounds, or with anything

wrong or apparently wrong. Danger may

be present that the hoist operator

cannot see. Determine and correct the

cause of unusual conditions and make

certain hoist can be operated safely.

5-2. INSPECTION OF LOWER BLOCK.

a) Check lubrication of all parts. Also lubricate

the shank of the hook that passes through

the crosshead. If the thrust bearing is

removed, apply MPG grease (Section IV,

Para. 4-7).

b) Check each sheave to insure rope groove

is smooth and free from burrs, or other

surface defects.

c) Check each sheave for freedom of rotation;

replace bearings if defective.

d) Make certain that the spring pin holding the

hook nut to the hook is securely in position.

e) If hook is equipped with a hook latch or

rotational lock, check to determine that they

are in good operating condition.

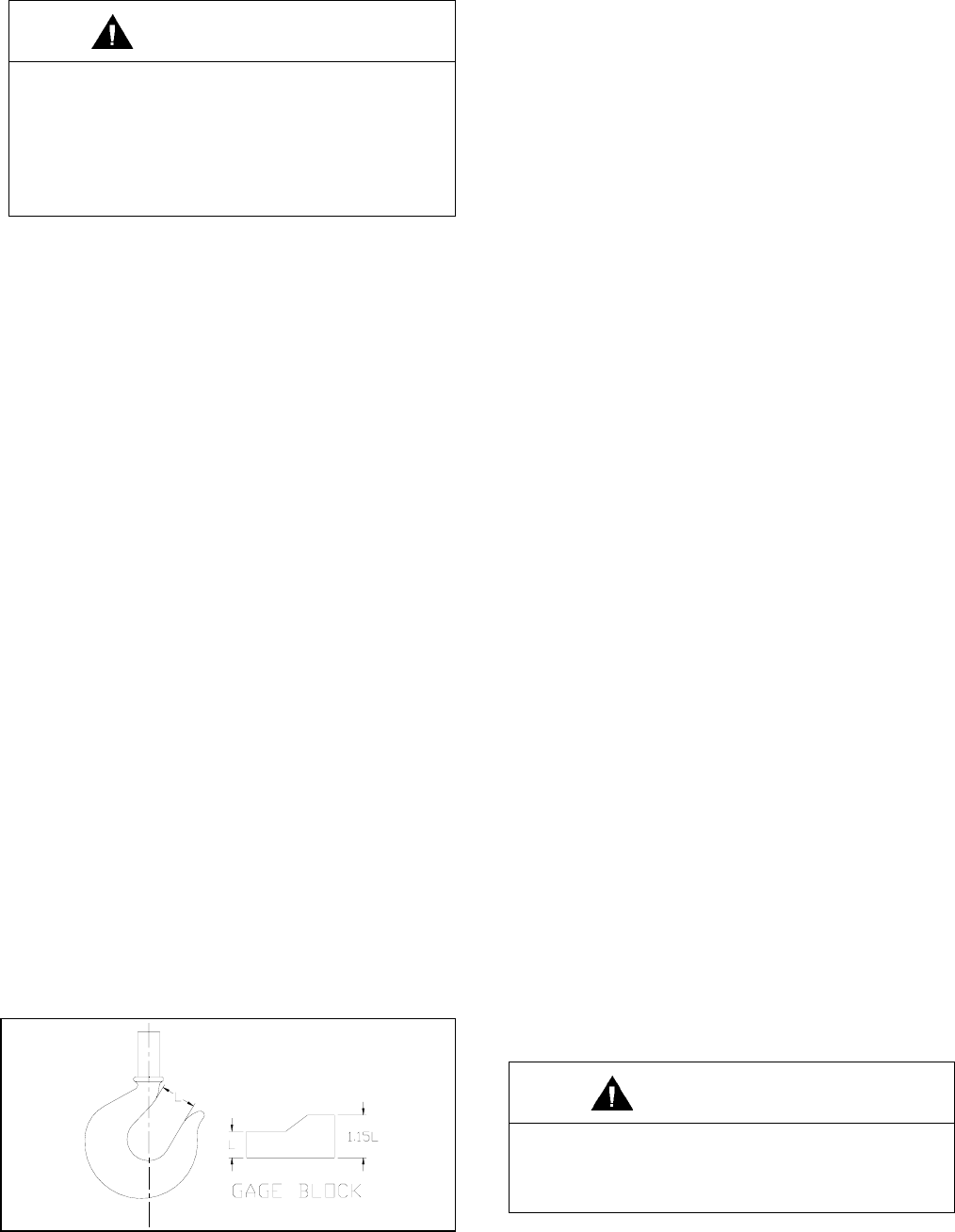

f) Check throat opening of the hook. (Refer to

Figure 5-2.) It is recommended that upon

receipt of the hoist, a measurement be

made and recorded of the hook throat

opening. OSHA regulations require that the

hook be replaced if the throat opening

exceeds 15 percent of the original opening,

or if the hook is twisted more than 10

degrees from the unbent plane. We

suggest that a gage block properly

identified to the hoist, similar to the one

shown in Figure 5-2, be made for each

hook for use in these measurements.

FIGURE 5-2 Gage Block.

g) Hooks showing signs of cracks must be

replaced. Hooks should be inspected at

least once per year using dye penetrants,

magnetic particle, or other suitable non-

destructive test methods.

h) Check wear of the hook, especially at the

saddle and replace if worn more than 10%

of original dimensions.

5-3. INSPECTION OF UPPER BLOCK.

a) Check upper block sheaves (when hoist is

so equipped) for wear, damage and

freedom of rotation.

If sheaves do not rotate freely, disassemble

block and inspect bearings. Replace worn

or damaged bearings, washers, pins, or

sheaves.

b) Make certain that all sheaves, bearing and

hanger pins are free of foreign material.

Bearings without grease fittings are

lubricated for the life of the bearing and

require no further lubrication.

c) Make certain that the rope retention bolts

are not bent, loose or otherwise distorted;

bolts must have close clearance to sheave

flange to keep rope in sheave grooves.

5-4. INSPECTION OF ELECTRICAL CONTROLS.

Arrangement of electrical control equipment varies

with the type of control, physical space and the

optional control features ordered with the hoist.

Note the location in the electrical enclosure of the

control circuit fuse, transformer, limit stop switches

and the hoist contactors. Trolley contactors and

optional hoist and trolley fuses are also located in

this enclosure.

Use wiring diagrams furnished with hoist to

determine electrical components on your hoist; then

determine component location and identity on your

hoist.

WARNING

Be certain that main power switch is

locked in open position (OFF) before

opening hinged control enclosure cover

mounted to the counterweight.

a) Open hinged control panel enclosure cover

mounted to the counterweight and inspect

wiring and terminals. Terminals should be