25

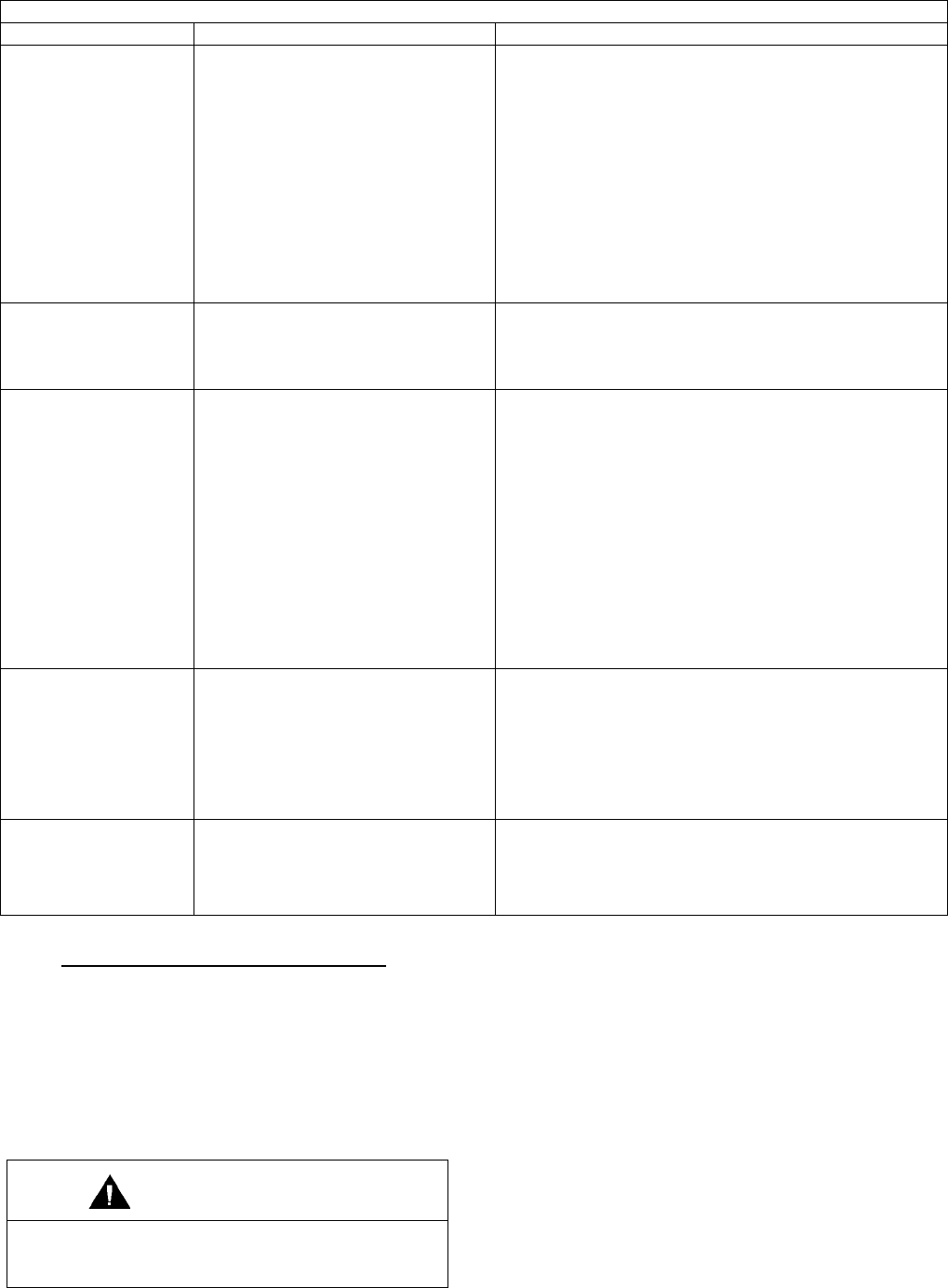

SECTION VI – TROUBLE SHOOTING

TROUBLE PROBABLE CAUSE REMEDY

6-4 Hook Will Lower,

But Not Raise.

a. Excessive load.

b. Hoist electrical circuit open.

c. Contactor assembly not

functioning.

d. Up, down button inoperative.

a. Reduce loading to rated load of hoist as shown on

nameplate.

b. Check for loose connections. See that necessary

jumper wires are properly installed on contactor.

c. See that necessary jumper wires are properly

installed. Verify that the contactor armatures are

free to move. If binding occurs, replace contactor.

Check for burned out contactor coils.

d. Check push button contacts and wires.

6-5 Hoist Will Not

Lift Rated Load.

a. Low voltage.

a. See that the power supply current is the same

voltage listed on motor data plate. Check hoist

motor connections. Check size of power supply

lines.

6-6 Hoist Motor

Overheats.

a. Excessive load.

b. Excessive duty-cycle.

c. Wrong voltage or frequency.

d. Defective motor or worn

bearings in hoist frame.

e. Brake not adjusted correctly.

a. Reduce loading to rated load as shown on

nameplate.

b. Reduce frequency of lifts or amount of jogging.

c. Check current rating on motor data plate against

power supply. Check hoist and inspect for

defective, worn or damaged parts.

d. Disassemble hoist and inspect for defective, worn

or damaged parts.

e. Adjust brake per Section VII, Paragraph 7-1.

6-7 Load Drifts

Excessively

When Hoist is

Stopped.

a. Excessive Load.

b. Motor brake not holding.

a. Reduce loading to rated load as shown on

nameplate.

b. With No Load, check hoist for drift. If drifting is

excessive, inspect motor brake (Section V,

Paragraph 5-10) and adjust as outlined in Section

VII, Paragraph 7-1.

6-8 Hoist Operates

Intermittently.

a. Collectors make poor contact.

b.

Loose connections.

a. Check collectors for free movement of spring arm,

weak spring or electrical connections.

b. Check all wiring for loose connections.

SECTION VII – ADJUSTMENTS

7-1. MOTOR BRAKE ADJUSTMENT. These

brakes are designed so that adjustment is seldom

required. If, after a period of service, the load hook

“drifts” downward more than usual for your hoist

before coming to a stop, the motor brake may

require adjustment to compensate for brake disc

wear.

WARNING

Check to be certain main power switch

is locked in open position (OFF) before

removing brake cover.

Refer to Figure 5-9 and proceed as outlined in

Section V, Paragraph 5-10.

7-2. BLOCK OPERATED LIMIT SWITCH. The

block operated limit stop, furnished as standard

equipment, is non-adjustable and designed to stop

the lower block at the safest high point of travel to

eliminate any possibility of double-blocking. When

the safest high point is reached, the limit switch

automatically stops hook travel.

7-3. GEARED ROTARY LIMIT SWITCH

ADJUSTMENT. The geared rotary type limit switch

is standard equipment and is located on the drum

end opposite the gearcase end.