18

torque the remaining two (2) rope

clamps in sequence to 50 ft-lbs.

(2) With all personnel clear of hoist – TURN

ON POWER.

(3) Operate hoist “UP” guiding six (6) wraps

of new rope into drum grooves with

gloved hand.

(3) Re-install rope guide over rope in rope

drum grooves as shown in Figure 5-3.

and outlined in Section V, Paragraph 5-6.

Continue lubricating as rope is spooled

onto the drum until about 28’-0” remain

unwound.

(7) With outer lower block covers removed,

thread the wire rope through the sheaves

of the upper and lower block as shown in

Figure 5-6.

(8) Attach swaged rope end to the dead end

anchor pin fastening cotter pins or

retaining rings as required.

(9) Replace the lower block sheave covers.

(10) Lubricate cable per Paragraph 4-3.

See Figure 9-5 (“B” Frame components) for

lower block parts with 7/16” diameter wire

rope.

See Figure 9-5 (“C” Frame components) for

lower block parts with 9/16” diameter wire

rope.

c) Checking for and removal of rope twisting.

(1) To remove rope twist in four part single

reeved hoists:

(a) Observe direction block tends to

rotate.

(b) Lower the block to a low position

and TURN OFF (lock out) POWER.

(c) Remove swaged fitting from anchor

pin and rotate rope several turns in

a direction tending to correct block

rotation.

(d) TURN ON POWER; raise and

lower the block several times to

feed the correcting twist in the rope

through the reeving.

5-8. INSPECTION OF ROPE DRUM AND SHAFT.

a) To remove the rope drum, remove the rope

guide and hoisting cable, as outlined in Section

V, Paragraphs 5-5 and 5-7.c. respectively.

WARNING

The hoist must be removed from service

and placed on the ground for any

maintenance that requires removal of

the output shaft assembly or drum.

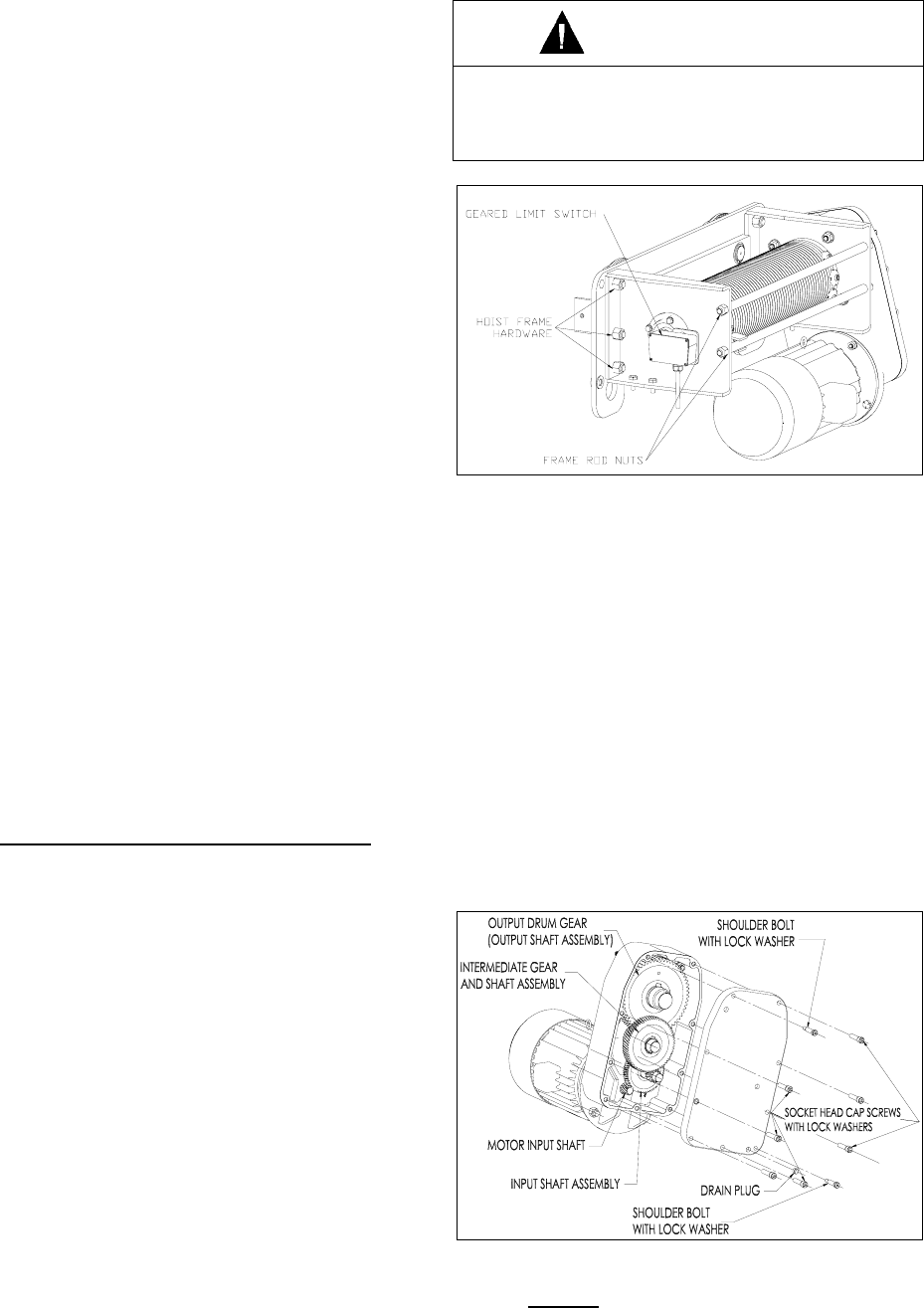

Figure 5-7. Drum Frame & Geared Limit Switch.

b) Remove the Geared Limit Switch or disconnect

the wires so that the electrical cable will not

inhibit removal of the drum. (See Figure 5-7).

c) Remove the unit from service, place it on the

ground, and provide adequate means to

support the drum before removing the frame

rod nuts at the outboard drum frame end

(Figure 5-7). The hardware attaching the drum

frame to the hoist and trolley frame may then

be removed.

d) Keeping the drum level, remove the drum from

the splined output shaft at the gear case end.

5-9. INSPECTION OF HOIST GEARING.

Figure 5-8. Hoist Gear Case Assembly.

a) General

. The hoist gear case is a triple

reduction splash lubricated vertically split

cast aluminum case and cover. The first

two high-speed reductions are helical and

the third low speed output reduction is