XLB-4319

4-8

To adjust the system hydraulic pressure, we must first set the outriggers bypass pressure

very high. This ensures that you are reading system pressure when fully retracting an

outrigger cylinder. After adjusting the system pressure, we must readjust the outriggers

bypass pressure to specification.

Adjust System Pressure

1. Connect a hydraulic pressure gage to the pressure test port.

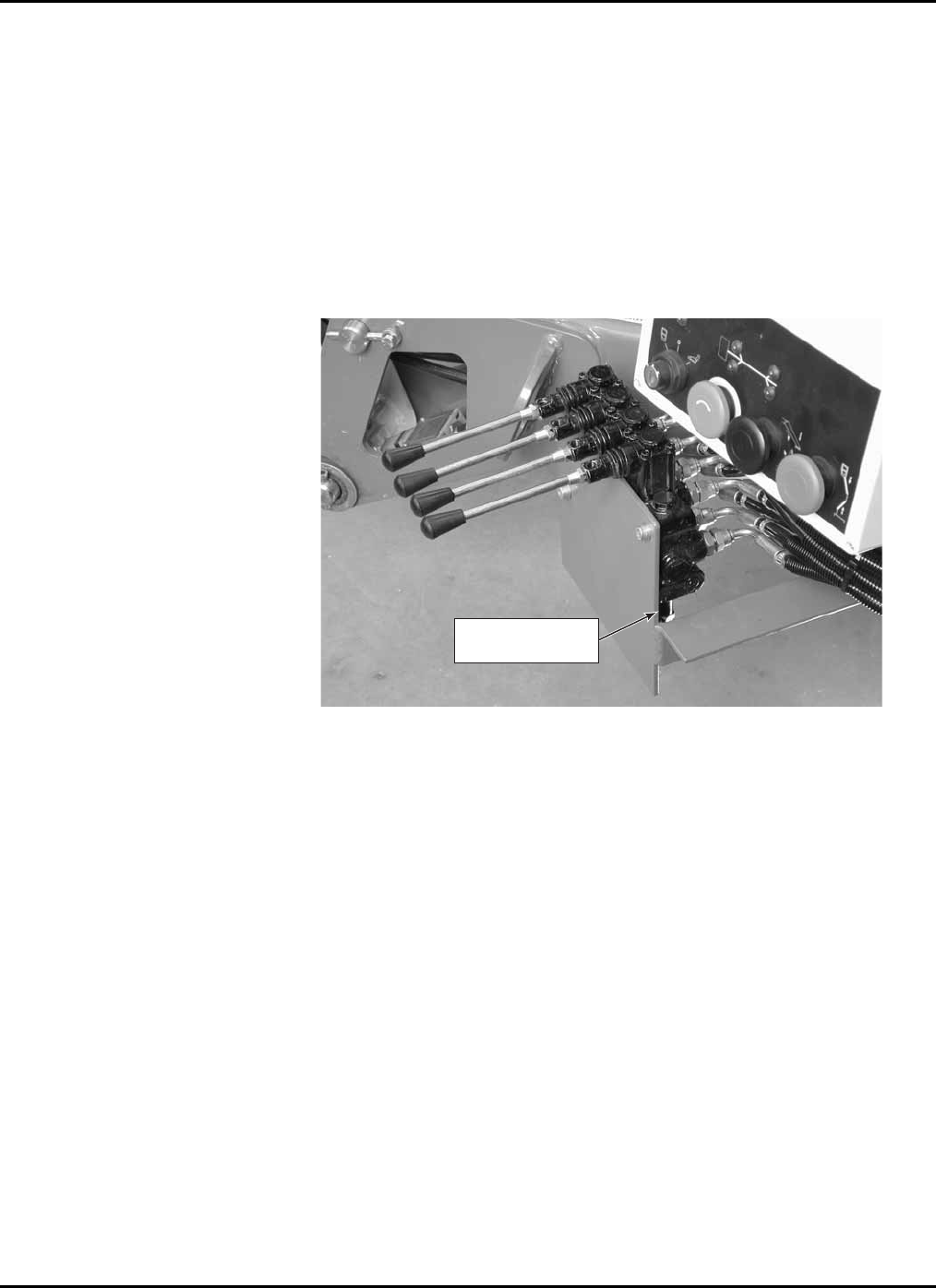

2. Remove the cap from the outriggers bypass valve (Figure 4-6). Turn the adjust

screw to the right exactly two turns. This adjustment will allow the main bypass

valve to regulate the test pressure.

3. Reinstall and tighten the cap to prevent oil leakage. Do not over tighten the cap.

OUTRIGGERS

BYPASS VALVE

Figure 4-6. Outriggers Bypass Valve

4. Start the gasoline engine or DC motor. Run the engine or motor for at least five

minutes to warm the hydraulic oil to the normal operating temperature.

5. Pull up one outrigger control lever to fully retract the outrigger. While the out-

rigger control lever is pulled up, read the pressure gage. If the pressure is rising,

allow the pressure to reach its highest reading.

6. On the gas model boom lift, if the pressure gage reading is 3045 psig [210 bar

(21 000 kPa)] nominal, no adjustment is required. If an adjustment is required,

proceed with step 8.

7. On the DC model boom lift, if the pressure gage reading is 2750 psig [190 bar

(19 000 kPa)] nominal, no adjustment is required. If an adjustment is required,

proceed with step 8.

NOTE: Loosening the adjust lock nut will cause hydraulic oil to leak from the

main bypass valve. It is recommended that you shut the engine off before

making adjustments to the main bypass valve.

8. Press the emergency stop pushbutton to turn off the hydraulic pump.

9. Loosen the adjust lock nut for the main bypass valve.