55

930336 Rev. E

XII. MAINTENANCE

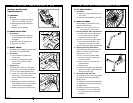

2. 10" (260 mm) Drive Wheels:

a. Elevate and securely support chair so that wheel is off the ground. Release

all air from tire.

b. Remove 4 center socket head screws (A) from rim using a 1/4"

allen wrench.

Note: Do not remove outer button head bolts at this time.

c. Make sure all air has been removed from tire. Remove the four bolts from

rim. Separate two halves of rim.

d. Repair or replace inner tube. Reassemble the wheel.

Use a torque setting of 120 in.-lbs. (13.5

N

.

m) to re-tighten bolts.

e. Install wheel on chair by replacing four center screws.

Use a torque setting of 300-350 in.-lbs. (34-40

N

.

m) to

re-tighten screws.

f. Inflate tire to proper pressure level (listed on tire sidewall).

G. MOTOR BRUSHES

Check the motor brushes every three (3) months for wear.The brushes

should be clean and shiny.Replace worn or blackened brushes.

H. ORDERING PARTS

When you order parts, provide the following:

1. Model of chair

2. Serial number of chair

3. Left hand or right hand control

4. Part number, description and quantity of parts you need.

5. State reason for replacement.

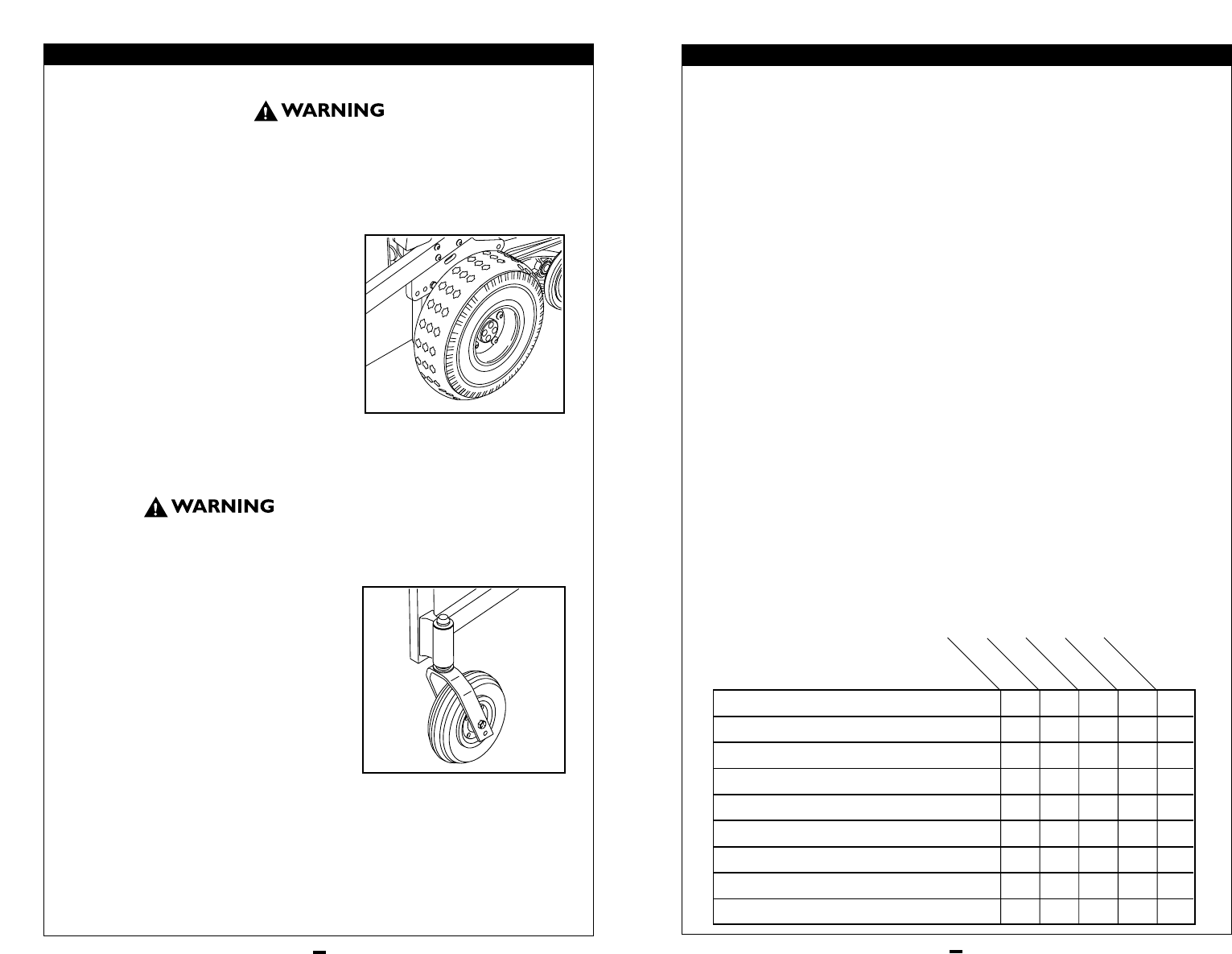

I. MAINTENANCE CHART

You should check the items on this chart at the indicated intervals. If any of the

items are loose, worn, bent or distorted, immediately have them checked and/or

repaired by your authorized Sunrise supplier. Frequent maintenance and servic-

ing will improve performance, extend wheelchair life, and help prevent injuries.

Charge Batteries

Check tires for proper inflation level

Check batteries for proper electrolyte level (wet only)

Check plugs and connectors for proper connections

Check all moving parts for wear

Inspect all nuts, bolts and fasteners for looseness or wear

Inspect upholstery for wear

Remove and inspect motor brushes

Servicing by authorized Supplier

CHECK...

✓

✓

✓

✓

✓

✓

✓

✓

✓

Quarterly

Annually

Monthly

Weekly

Daily

54

930336 Rev. E

1. Check for signs of wear and correct

air pressure in pneumatic tires weekly.

2. For best performance, inflate tires to

the same pressure level, as shown

on the tire sidewall:

• 8" (200 mm) pneumatic casters -

30 to 40 psi (207 to 275 kpa)

• 10" (260 mm) pneumatic drive

wheels-35 to 45 psi (240 to 310 kpa)

3. Caution:

To prevent tire damage:

• Use a hand pump (or a low

volume air pump) to inflate tires.

• Use a tire gauge to check pressure.

F. TO REPAIR OR REPLACE A TIRE

Residual air pressure in tires can cause severe

injury. Make sure you release all air in tire

before attempting to service or repair tires.

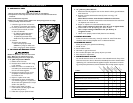

1. 8" (200 mm) Caster Wheels:

a. Release all air from tire.

b. Remove caster wheel from fork using

a 1/2" wrench.

c. Make sure there is no residual air in

tire before you remove bolts that hold

the two rim halves together.

d. Remove four bolts from rim using a

#3 phillips screwdriver.Separate

two halves of rim.

e. Repair or replace inner tube.

f. Reassemble the caster wheel; make

sure the bearing spacer is in place and

all four bolts are tightened to a torque

of 60 in.-lbs. (6.8

N

.

m).

g. Mount caster wheel onto fork.

Install washers correctly tighten bolt

to 240 in.-lbs. (27

N

.

m).

h. Inflate fire to proper pressure level.

XII. MAINTENANCE

E. PNEUMATIC TIRES

1. Do not use this chair if any of the tires are under- or over-inflated.

2. Low pressure in a tire may cause the chair to veer to one side and result in loss

of control.

3. An over-inflated tire may burst.

4. Never use a gas station pump to inflate a tire. Such pumps provide air at high

volume, and may cause tire to burst.