Installation

Topics Covered in this Chapter

♦ Location

♦ Install Air Solenoid

♦ Install Electronics Box and LCM

♦ Install Pressure Transducers

♦ Connect Air Hoses and Cables

Shutdown the XP Sprayer before installing your

pressure monitor kit. Follow the Shutdown and

Pressure Relief Procedure in the XP Sprayer

operation manual. All electrical wiring must be

done by a qualified electrician and comply with all

local codes and regulations.

The procedures in this section are specific to each

component of the pressure monitor kit. For sprayer

installation instructions, refer to the XP70 Sprayer

Operation manual.

Location

These pressure monitoring kits are not approved

for use in hazardous atmosphere locations.

Installing this kit on a XP Sprayer that is EX

approved, voids the approval. The EX mark should

be removed from the machine ID plate when this

kit is installed.

NOTICE

Do not store a XP Sprayer with a pressure monitor

kit outside in the rain. Use protective bag 16J717

to prevent damage to the electronic components,

used with the pressure monitor kit, when stored

outside.

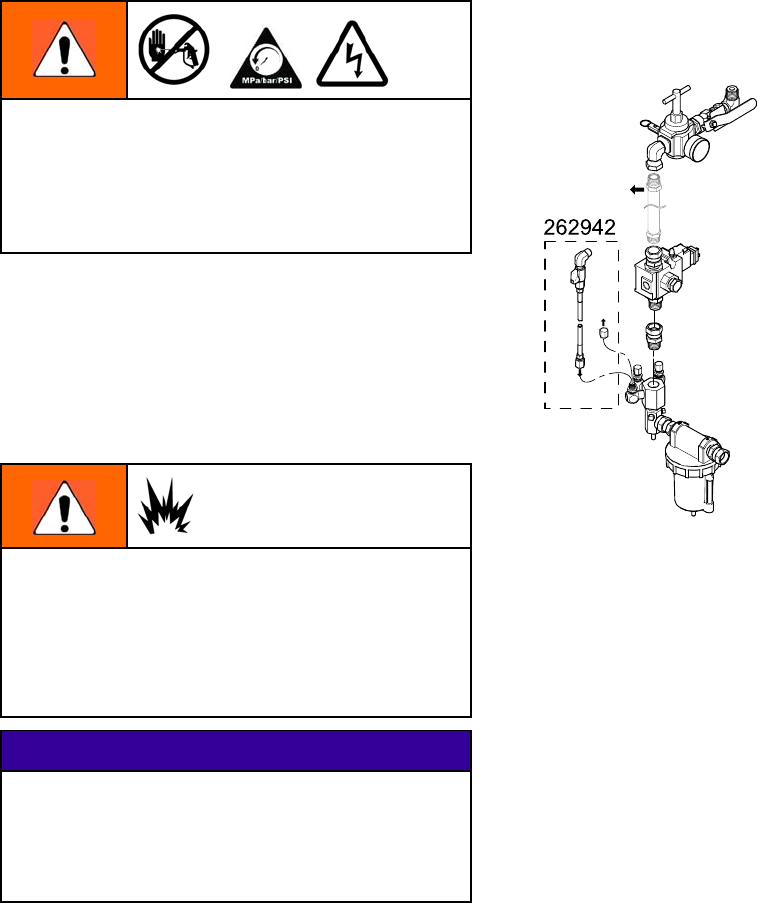

Install Air Solenoid

1. Disconnect the upper swivel and remove the

motor air line from the lower air manifold.

Note

On early XP sprayers, to remove the

existing air hose, it may be necessary to

remove the air filter assembly from the

XP and put it in a vice. New models XP

sprayers have an additional hose union.

2. For the turbine powered kit 262942, remove a

plug from the air manifold and install the 5/16 in.

x 4 ft (1.2 m) air hose.

Figure 8

3. Connect the air solenoid valve and new motor

air hose to the air inlet assembly. Ensure that

the air solenoid valve cable faces the back of

the machine.

8 3A1331C