Instruction Bulletin

106-300NE Rev. 3.4

May 2000

Rosemount Analytical Inc. A Division of Emerson Process Management Description 1-3

World Class 3000

6. Suitable for use in temperatures up to

1300°F (700°C).

7. Heater power supply allows World

Class 3000 probe to be interfaced with

existing analog and 218A digital

electronic packages.

8. Optional explosion-proof HPS enclo-

sure allows use in hazardous gas

areas.

e. Handling the Oxygen Analyzer

It is important that printed circuit

boards and integrated circuits are

handled only when adequate antistatic

precautions have been taken to

prevent possible equipment damage.

The oxygen analyzer is designed for

industrial application. Treat each

component of the system with care to

avoid physical damage. The probe

contains components made from

ceramics, which are susceptible to

shock when mishandled.

NOTE

Retain packaging in which the oxygen

analyzer arrived from the factory in

case any components are to be

shipped to another site. This packag-

ing has been designed to protect the

product.

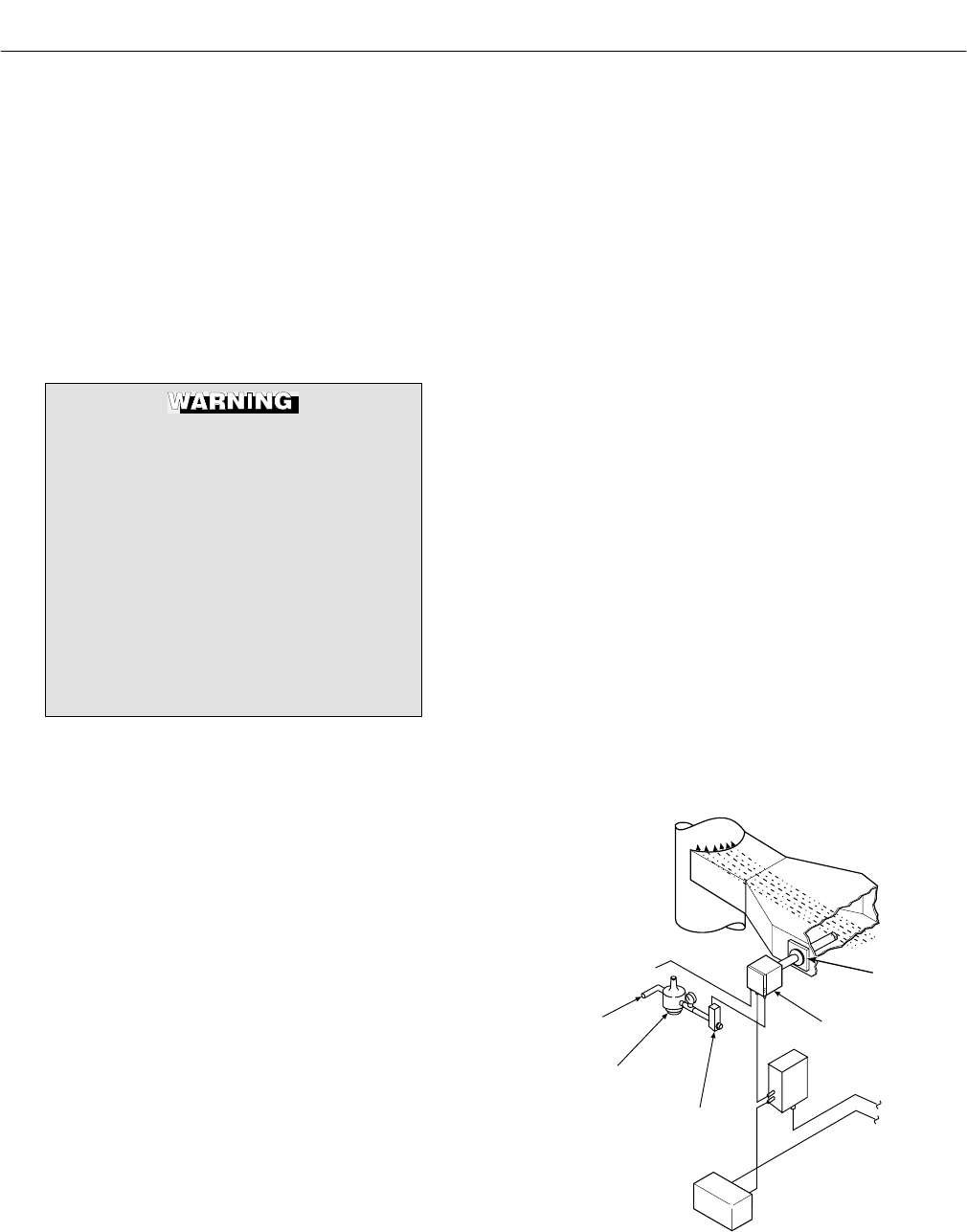

f. System Considerations

Prior to installation of your Rosemount

World Class 3000 Oxygen Analyzer with

Heater Power Supply Field Module, make

sure you have all of the components neces-

sary to make the system installation. Ensure

all components are properly integrated to

make the system functional.

Once you have verified you have all the

components, select mounting locations and

determine how each component will be

placed in terms of available power supply,

ambient temperatures, environmental con-

siderations, convenience, and serviceability.

A typical installation is illustrated in Figure

1-2 and Figure 1-3.

After selecting the probe mounting location,

provision should be made for a platform

where the probe can be easily serviced.

The heater power supply can be located up

to 150 feet (45 m) cable distance from the

probe.

A source of instrument air is required at the

probe for reference gas use. Since the

probe is equipped with an in place calibra-

tion feature, provision should be made for

connecting test gas tanks to the oxygen

analyzer when the probe is to be calibrated.

NOTE

Ambient air is not recommended for

use as high test gas. An 8% O

2

bal-

ance in nitrogen is recommended for

high test gas.

If test gas bottles will be hooked up perma-

nently, a check valve is required next to the

calibration fittings on the probe junction box.

This is to prevent breathing of calibration

gas line and subsequent flue gas conden-

sation and corrosion. The check valve is in

addition to the stop valve in the test gas kit

or the solenoid valve in the multiprobe test

gas sequencer units.

}

19260002

DUCT

STACK

GASES

CALIBRATION

GAS

INSTRUMENT

AIR SUPPLY

(REF. GAS)

PRESSURE

REGULATOR

FLOWMETER

ELECTRONICS

PACKAGE

OXYGEN

ANALYZER

(PROBE)

ADAPTER

PLATE

LINE

VOLTAGE

HEATER POWER

SUPPLY

Figure 1-2. Typical System Installation

1