PAGE 76 — C-30HD — PARTS & OPERATION MANUAL — REV. #4 (03/06/01)

C-30HD — SERVICE PROCEDURES

1. CRANKSHAFT AND CAM ASSEMBLY PROCEDURE

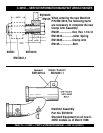

A. Set bearing block (part #EM14303) into hydraulic press.

Place bearing cup into bearing block and press in evenly.

Bearing cup should be aligned equally on both sides of bearing

block.

B. Set crankshaft into hydraulic press with the long end

towards the top. Install spacer (part #EM14322), O-ring (part

#EM14326) and bearing cone (part #EM14325) onto

crankshaft. Place bearing block on crankshaft until the bearing

cone is riding in the bearing cup. Insert bearing cone spacer

(part #EM14323) onto crankshaft and inside bearing block.

Install second bearing cone until it is seated inside bearing

cup. Place O-ring and spacer (part #EM14302) on crankshaft.

Set cam weldment on top of spacer. Install crankshaft key and

cam key on cam bushing (part #EM14301). Slide cam bushing

down crankshaft and align the bushing, cam and crankshaft.

Install sleeve over crankshaft and align with hydraulic press.

Install cam bushing bolts loosely. Press bushing down onto

bearing assembly. Leaving pressure on the bushing, tighten

cam bolts evenly to 40-50 foot pounds. Release pressure on

the bushing, re-apply pressure to bushing and tighten bolts

evenly to 40-50 foot pounds. Repeat procedure 3 to 4 times.

After bushing is tight into cam, remove from hydraulic press.

Remove one bolt at a time, using Loctite, install bolts and

torque to 65-70 foot pounds. Counter sink set screw hole and

install dog point set screw and second set screw both with

Loctite.

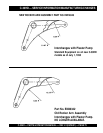

C. Place cam bearing onto crankshaft keeping bearing loose.

*Note: Make sure the eccentric lock is facing toward the outside

of the pumping unit.

D. Set crankshaft assembly into the pump box and align both

bearing assemblies with the pump box mountings.

E. After crankshaft assembly is securely fastened to the pump

box, place sprocket (part #EM14307) onto the cam side of

the crankshaft assembly. Install bushing (part #EM14309) into

sprocket. Align sprocket with sprocket on countershafts and

tighten bolts.

F. Install chain part #EM14308. To adjust, loosen locknuts on

pusher bolts and tighten chain to approximately 1/2” slack in

the chain. Once chain is adjusted properly, tighten down

locknuts.

2. BALL AND SEAT REPLACEMENT PROCEDURE

A. Remove 3”x 2” reducer and 3” elbow from the pump outlet.

Remove exhaust gate and Y-manifold (secondary manifold).

Check ball seat and ball stop pin for wear. If any wear is

detected, the part should be replaced. Remove T-manifold

(primary manifold). Check all parts for wear. Remove hopper

and hopper seat and inspect.

B. Loosen the piston nuts and remove the piston cup assembly

and cylinders. Inspect all parts for wear and replace parts with

excessive wear. Check oiler pump for proper operation.

C. Clean all parts thoroughly, removing all foreign material and

concrete slurry. Once parts are clean, install concrete cylinders.

Place oiler plate O-ring in place and coat with oil. Install small

O-ring on piston rod. Run oiler line through the cylinders and

connect in the oiler fitting on the oiler plate. Push oiler plate

into cylinder. Install ring and felt holder, soak felt ring in oil,

then install around felt holder in cylinder. Make sure the bronze

ring is flat, then push it up flush with the ring and felt holder.

Coat piston cup with oil and push it inton the cylinder. Install

bushing into center of piston cup. Put small O-ring on rod, place

face plate on rod and tighten down securely. Repeat these

procedure on the opposite cylinder.

D. Thoroughly check T-manifold, ball stoppings and both steel

balls for wear. Insert an O-ring in the top flange and in the

leading edge of the manifold. Put the manifold onto the primary

side of the pump and install bolts leaving them loose.

E. Check Y-manifold for wear, install all O-rings, ball stop pin,

ball and seat. Align and install Y-manifold to T-manifold and

cylinder assembly. Tighten Y-manifold bolts first before

tightening T-manifold bolts. After manifolds are tight, check O-

rings for slippage.

F. Insert seat into frame hole directly above the T-manifold.

The seat orifice should fit inside the frame itself, then the seat

sits on top of the orifice. On the dura-seat, set the big end of

the seat in the frame. The seat, or the small part of the dura-

seat, fits into the bottom of the hopper.

G. After tightening the manifold bolts and inserting the seats

in place, set the hopper over the seat and align the bolt holes.

Tighten bolts, check O-ring and seat for alignment.

H. Check exhaust gate for wear, install and align gate onto Y-

manifold. Insert O-ring into exhaust gate flange and close gate.

Lock down lever and adjust clamp arm.

I. Install 3” elbow and 3”x 2” reducer. Fill hopper half full and

check for leaks.