INFINITY

Residential Elevator

Specifications for Part 5.3 Compliance

PART 1 - GENERAL

SCOPE

To furnish all labor, materials and equipment necessary or required to

fully complete the installation of the elevator as indicated on the

Drawings and Specifications. This suggested specification is intended to

cover the complete installation of the Concord INFINITY Residential

Elevator design.

SYSTEM DESCRIPTION

The elevator assembly shall consist of a power unit, car, guide system,

1:2 cable hydraulic lifting device, control system, signals and alarms,

electrical wiring, and parts and accessories necessary to provide

required performance, operation, code and safety requirements.

QUALITY ASSURANCE

1.3.1

The elevator shall meet or exceed the applicable regulations of all

governing agencies and be in conformance with the applicable sections

of the most current edition of the following codes and standards:

a) ASME A17.1 "Safety Code for Elevators and Escalators;

"Private Residence Elevators". CAN/CSA B44 Part 5 Section 5.3

b) ICC/ANSI A117.1-1998 "Accessible and Usable Buildings and

Facilities".

c) NFPA 70-1999 "The National Electric Code" (NEC).

d) ADAAG "Americans With Disabilities Act Accessibility

Guidelines" (where applicable).

e) CSA B44.1/ASME A17.5 "Elevator and Escalator Electrical

Equipment"

f) Local codes and regulations, as applicable.

1.3.2 REQUIREMENTS OF THE REGULATORY AGENCIES

a) Fabricate and install work in compliance with all applicable

jurisdictional authorities.

b) File shop drawings and submissions to local authorities as the

information is made available. Company pre-inspection and

jurisdictional authority inspections and permits are to be made

on a timely basis as required. Work will include all inspections

and re-inspections that are required to ensure licenses are

issued.

1.3.3 SUBCONTRACTOR QUALIFICATIONS

a) Execute work of this specification only by a contractor/company

who has adequate product and public liability insurance in

excess of one million dollars.

b) Skilled tradesmen must be employees of the contractor and

perform the work on a timely basis. Employees must be trained

by the manufacturer and be supervised by the elevator

contractor.

1.3.4 SUBSTITUTIONS

No substitutions will be considered unless written request for approval

has been submitted by the bidder and received by the architect at least

10 days before the receipt of bids. Each such request shall include a

complete description of the proposed substitute including drawings, test

data, photographs, and any other information needed for consideration.

PART 2- PREPARATORY WORK BY OTHERS

2.1

The following preparatory work to accommodate/receive the elevator is to

be done by others.

2.1.1

Provide power unit machine room to meet applicable Codes and

Standards.

2.1.2

Permanent power (220 Volt, Single Phase, 30 Amp or 208 Volt, 3 Phase,

30 Amp.) to operate the elevator to be provided to a Lockable

Fused/Cartridge Type Disconnect Switch with auxiliary contact/switch for

emergency battery lowering. Refer to architectural drawings for

permanent power specifications and location of disconnects.

2.1.3

Provide 110-volt lighting supply and disconnect. Refer to architectural

drawings for permanent power specifications and location of disconnects.

2.1.4

Provide an enclosed, plumb and square hoistway with smooth interior

surfaces. Include for fascias or furring of hoistway interior where

applicable.

2.1.5

Provide doors, frames, and door hardware.

Provide rough openings as per elevator contractor’s drawings.

2.1.6

Provide substantial, level pit floor slab to support loads indicated on

elevator contractor’s shop drawings.

2.1.7

Provide adequate support for guide rail fastenings.

2.1.8

Provide pit water proofing to maintain a dry pit. Sump pump where

required by authority having jurisdiction. (see elevator contractor for

location).

2.1.9

Provide 8" (203 mm) minimum pit.

2.1.10

Provide 92" (2337 mm) minimum overhead (distance from floor at upper

level to underside of roof).

PART 3 – SUBMITTALS

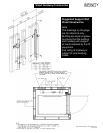

3.1 SHOP DRAWINGS (presentation)

The shop drawings shall show a complete layout of the elevator

equipment detailing dimensions, clearances and location of machinery.

Including the following:

a) Drawings show the dimensions including plans,

elevations, and sections to show equipment locations.

b) Load and reaction drawings shall be provided by the elevator

manufacturer and detailed on drawings.

CPG-INFVER01 © 2004, Concord Elevator Inc.

Page 6 of 12