(I-0320--.doc/13)

13

VIII TROUBLESHOOTING

A. Actuator Does Not Align Plug (130) to Port.

1. Check the multiport/actuator connector for looseness.

2. Check the Switchpak/actuator connector for looseness.

3. Check the motor for stalling or overload.

4. Check the speed reducer for visual leakage or noisy gear.

5. Check the accuracy of the position encoder itself (see manual RD-00232, “MultiPort Electronic

Controller with MP-800 Board).

6. Refer to the Multiport Electronic Controller service manual (RD-00232) for port calibration

procedures.

B. Plug Seal Assembly Leaks.

1. Refer to specification for rated differential pressure limitations.

2. Check the indicator plate and pin to ensure that the plug is aligned with the port .

3. Check the seal for damage (CAUTION: Ensure that all pressures in the Multiport body, group

outlet, and test port are ZERO before visually checking the seal). With the multiport selector and

piping at zero pressure, remove the test port blind flange and visually check for plug seal assembly

damage (ie. Scratches) as the plug seal passes the test port .

4. If more information is required contact the factory.

C. Plug to Bonnet Stem Seal Leaks to Atmosphere.

NOTE: This section applies to NPS 3" ANSI 900/1500 and NPS 4" Multiports only.

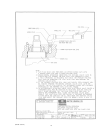

Refer to the injection system drawing I-0240 on page 18. Recommended sealant is Sealweld D-1014 or

equivalent.

1. The Multiport Flow Selector is shipped with the service valve (174) in the normally closed

position.

2. To determine if the primary seal has failed, remove the vent plug (176) from the service valve and

gradually open it. Any leakage occurring past the primary seal will drain out of the open service

valve.

3. If more information is required, contact the factory.