Large Dehumidifying Dryers Troubleshooting 49

Chapter 7: Troubleshooting

7-1 Introduction

The utmost in safety precautions should be observed at all times when working on or around

the machine and the electrical components. All normal trouble-shooting must be

accomplished with the power off, line fuses removed, and with the machine tagged as out of

service.

Before making haphazard substitutions and repairs when defective electrical components are

malfunctioning, we recommend that you check the associated circuitry and assemblies for

other defective devices. It is common to replace the obviously damaged component without

actually locating the real cause of the trouble. Such hasty substitutions will only destroy the

new component. Refer to wiring diagrams and schematics.

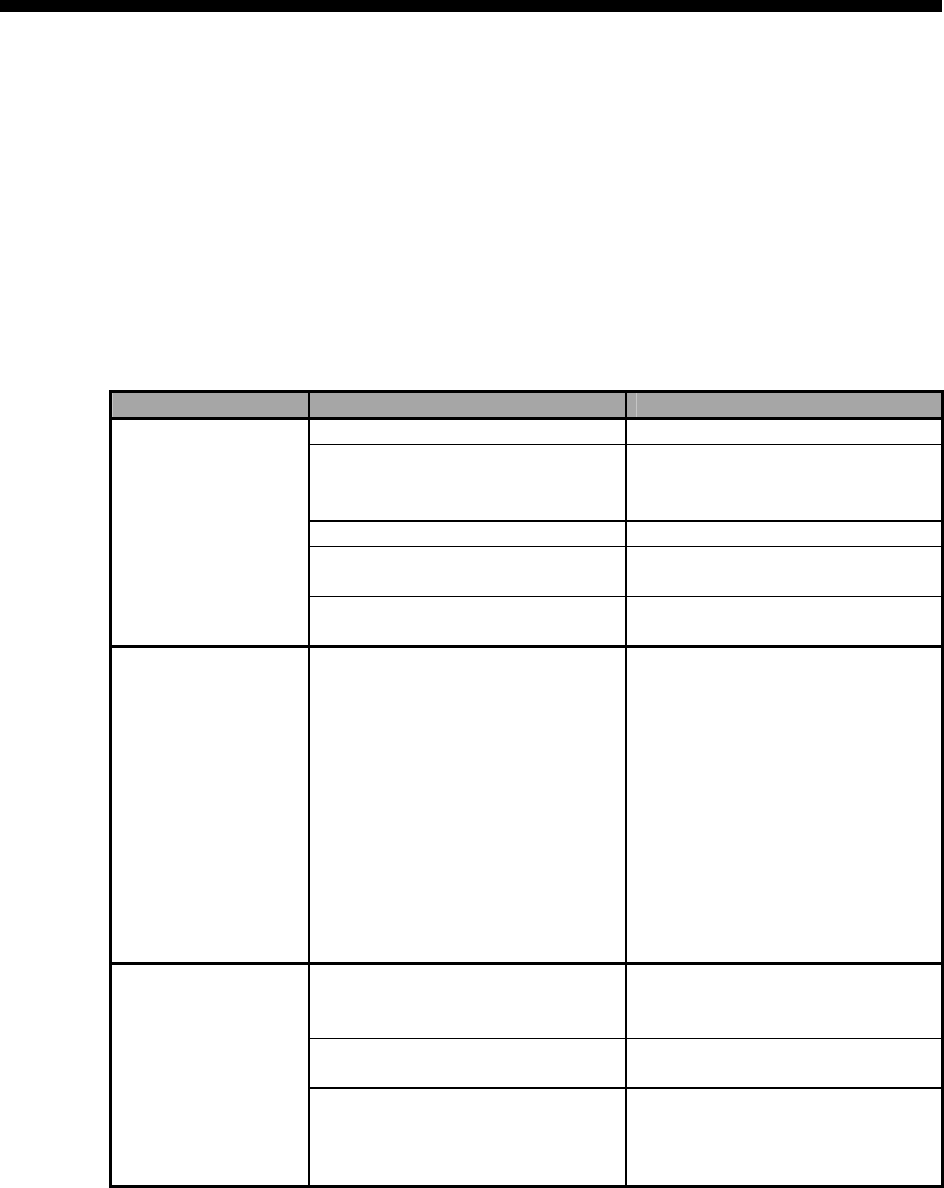

7-2 Basic Troubleshooting

Problem Possible Cause Corrective Action

Dirty Filters Clean or replace filters.

Desiccant beds contaminated by

material or plasticizer leaking

into the system.

Replace desiccant See page 46.

Blower fuse(s) blown. Fix problem and Replace fuse(s).

Overload tripped. Fix problem and reset the

overload.

Little or no air

coming from

process delivery

tube.

Blower fins filled with dust or

contaminants.

Remove blower side plate, clean

baffles, replace.

Suction in delivery

tube, pressure from

the return tube.

Phase is reversed on power drop

coming into the dryer.

Stop the Dryer.

If the dryer was connected to the

drying hopper, check to see if the

desiccant and process air heater

has been contaminated with resin.

If so, replace the desiccant and

remove any resin carry-over.

Otherwise, change the phase of

two legs of the three-phase power

drop. Never change the phase at

the motor starters unless only one

of the two blowers is rotating

improperly.

Process heaters are faulty.

Check for open or shorted heaters.

Replace if required. Check the

fuses.

Solid-state temperature controller

faulty.

Replace.

Loss or reduction of

process air

temperature.

Process temperature was adjusted

in error by plant personnel.

Make sure that plant personnel are

aware of the proper temperature

set point. A sign posted next to the

control would be helpful.