Positioning Control Positioning by AC Servo System 2

2-3

2.2 Examples of AC servo systems

• Positioning indicates the operation to move an element, such as a workpiece or tool (drill or

cutter) from a certain position (point) to another target position (point) and stop it with high

efficiency and high precision.

• In other words, the principle of positioning is the control of speed in accordance with the

position, performed to promptly eliminate the remaining distance to the target position. The

flexibility to change the target position electrically and easily is an important requirement.

• Several cases of positioning using an AC servo motor are systematically shown below.

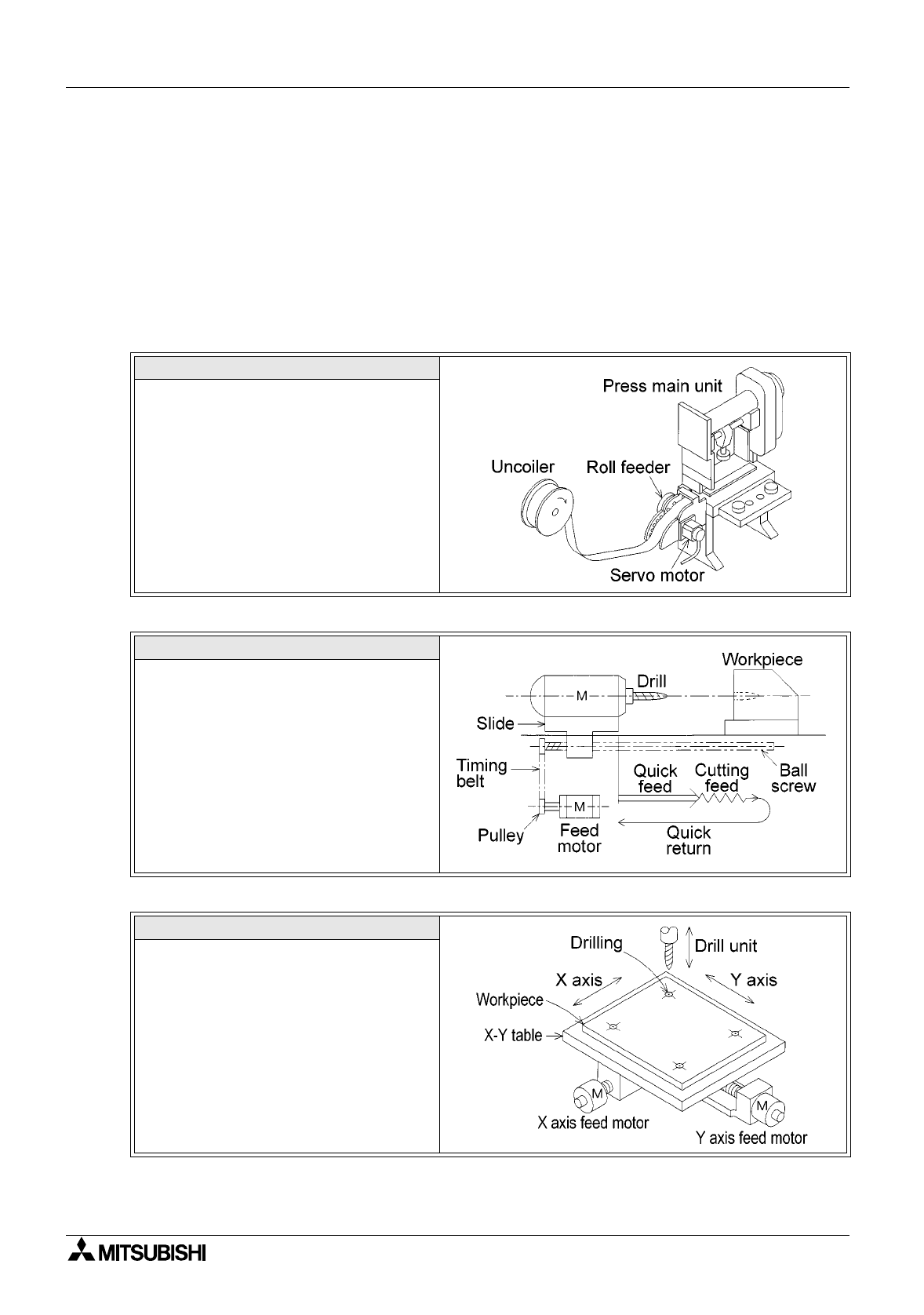

Constant feed

In the press/shear process for cutting,

punching, etc., the processed material is

positioned with high precision to produce a

constant sized product.

Tapping

In order to tap a workpiece, "1. Quick

feed", "2. Cutting feed" and "3. Quick

return" are repeatedly performed.

Drilling in steel sheet

In order to perform processing on a flat

face, positioning with high precision is

performed by two motors (X axis feed

motor and Y axis feed motor).