49

This Procedure includes the following:

Replacing Motor/Gearbox

MOTOR/GEARBOX PROCEDURE 13

M

O

T

O

R

/

G

E

A

R

B

O

X

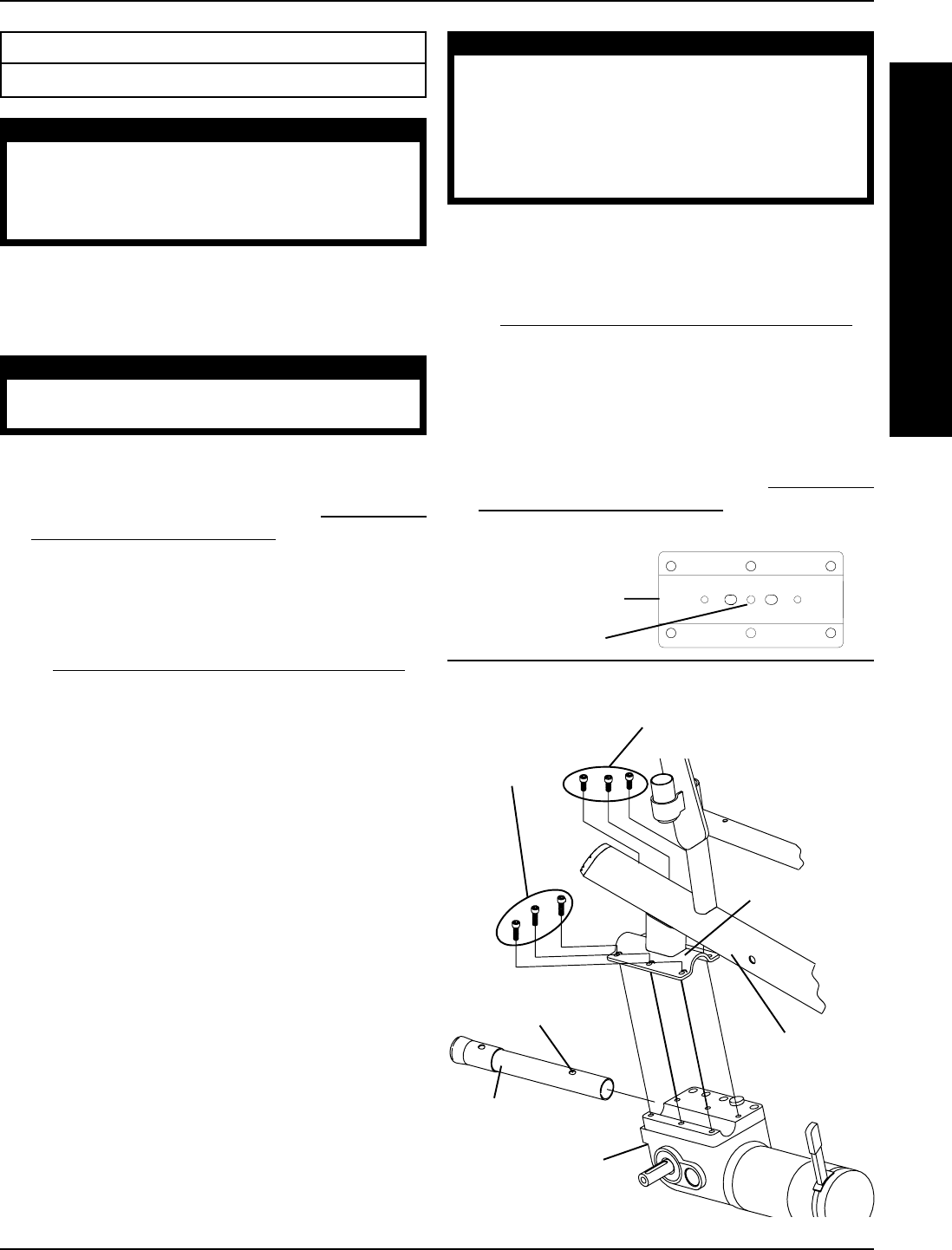

FIGURE 1 - REPLACING MOTOR/GEARBOX

Wheelchair

Frame

Long Socket

Screws (Apply

Loctite 242 and

torque to 60-

inch pounds)

Alignment

Hole

Motor Mount

Plate

Short Socket Screws

(Apply Loctite 242 and

torque to 60-inch pounds)

DETAIL "A"

Motor Mount Plate

Alignment Pin

Support Tube

Motor/Gearbox

(Standard Motor

Shown)

WARNING

After ANY adjustments, repair or service and BE-

FORE use, make sure all attaching hardware is

tightened securely - otherwise injury or damage

may result.

CAUTION

The longer socket screws must be positioned in

the mounting holes on the OUTSIDE of the wheel-

chair frame and the short socket screws must be

in the mounting holes on the INSIDE of the wheel-

chair frame. Otherwise damage to the gearbox

casting can result.

7. Use Loctite 242 and securely tighten the support tube

and motor/gearbox to the wheelchair frame with the

six (6) socket screws. Torque to 60-inch pounds.

8. Reinstall the rear wheels onto the wheelchair. Refer

to

INSTALLING/REPLACING REAR WHEELS in

PROCEDURE 12 of this manual.

9. Reconnect the right and/or left motor connector to the

controller.

10. Repeat procedure for opposite side of the wheelchair,

if necessary.

11. Reinstall the battery boxes. Refer to

INSTALLING/

REMOVING BATTERY BOXES in PROCEDURE 8

of this manual.

REPLACING MOTOR/GEARBOX

(FIGURE 1)

WARNING

The following procedure should only be per-

formed by a qualified technician.

NOTE: The following procedure can be followed for either

BASIC , STANDARD or 250 SERIES motor/gearboxes.

1. Remove the battery boxes. Refer to INSTALLING/

REMOVING BATTERY BOXES in PROCEDURE 8

of this manual.

2. Disconnect the right and/or left motor connector from

the controller.

3. Remove the rear wheels from the wheelchair. Refer

to

INSTALLING/REPLACING REAR WHEELS in

PROCEDURE 12 of this manual.

4. Remove the six (6) socket screws that secure the

motor/gearbox and support tube to the wheelchair

frame.

5. Reposition new motor/gearbox on wheelchair frame.

6. Position the support tube between the wheelchair

frame and the new motor/gearbox. Make sure the

alignment hole in the support tube is positioned with

the alignment pin on the motor mount plate.

NOTE: The alignment pin is the longest of the three (3)

pins and is located in the center of the wheelchair frame

motor mount plate. Refer to DETAIL "A" in FIGURE 1.

NOTE: When the alignment hole in the support tube is

positioned with the alignment pin on the wheelchair frame,

the anti-tipper wheels should be pointing down towards

the ground/floor.