9

Use of a condensate removal pump is permitted when nec-

essary. This condensate pump should have provisions for

shutting off the control voltage should a blocked drain occur.

A trap must be installed between the unit and the conden-

sate pump.

IMPORTANT NOTE: The evaporator coil is coated with oils

that may dissolve styrofoam and certain types of plastics.

Therefore, a removal pump or float switch must not contain

any of these materials.

Tip: Priming the “P” trap may avoid improper draining at the

initial installation and at the beginning of the cooling season.

When coils are installed above ceilings, or in other locations

where damage from condensate overflow may occur, it is

MANDATORY to install a field fabricated auxiliary drain pan

under the coil cabinet enclosure. Drain lines from the auxiliary

pan must be installed and terminated so that the homeowner

can see water discharges.

Achieve 2% Low Leakage Rate

Ensure that the Neoprene gasket with PSA remains intact on

all surfaces that the access panels are secured to. These

surfaces are the entire length of the wrapper and areas be-

tween the upper tie plate, upper and lower access panels.

Be sure that upper access panel breaker insert gasket is in-

tact and also flowrator gasket is installed on the lower ac-

cess panel. An additional drain hole cover is required.

ASPF Motor

The ASPF air handler features an energy efficient blower

motor. The motor is a constant torque motor with very low

power consumption. The motor is energized by 24 VAC. Ad-

just the CFM by changing the 24 VAC leads to the desired

speed on the terminal block.

The ASPF motor blower speed is programmed to deliver ad-

equate airflow at rated external static pressure and with 60

second off time delay. For details, refer to the specification

sheet applicable to your model.

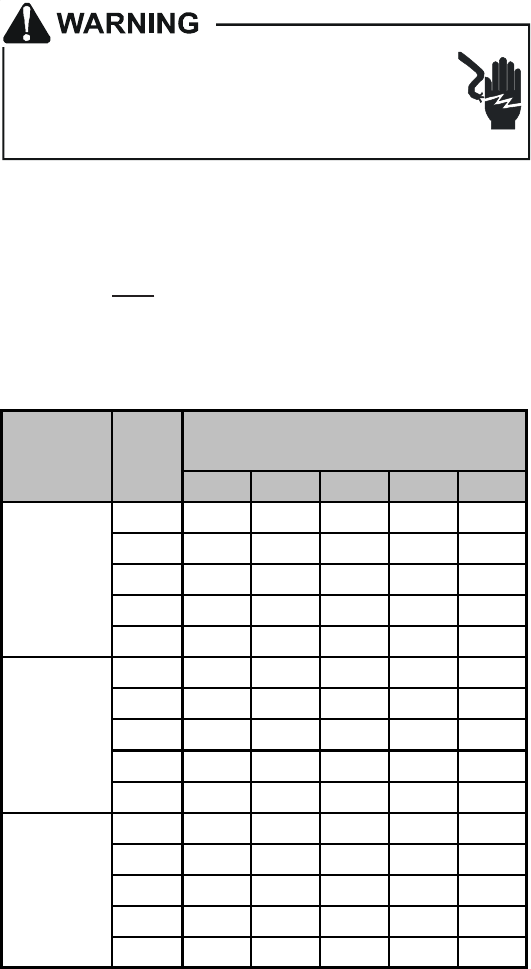

CFM Delivery

Table 9 shows the CFM speed tap settings for the ASPF.

Start-Up Procedure

• Prior to start-up, ensure that all electrical connections

are properly sized and tightened.

• All panels must be in place and secured. For Air Tight

application, neoprene gasket must be positioned at pre-

scribed locations to achieve 2% leakage.

• Tubing must be leak free.

• Unit should be elevated, trapped and pitched to allow

for drainage.

• Low voltage wiring is connected.

• Auxiliary drain is installed when necessary and pitched

to allow for drainage.

• Drain pan and drain tubing has been leak checked.

• Return and supply ducts are sealed.

• Unit is elevated when installed in a garage or where

flammable vapors may be present.

• Unit is protected from vehicular or other physical dam-

age.

• Return air is not obtained from any areas where there

may be objectionable odors, flammable vapors or prod-

ucts of combustion such as carbon monoxide (CO),

which may cause serious personal injury or death.

Regular Maintenance

HIGH VOLTAGE!

Disconnect ALL power before servicing or

installing this unit. Multiple power sources may

be present. Failure to do so may cause property

damage, personal injury or death.

The only item to be maintained on a regular basis by the user

is the circulating air filter(s). Filter should be cleaned or re-

placed regularly. A certified service technician must perform

all other services.

NOTE: DO NOT USE THESE DIAGRAMS FOR MODELS

OTHER THAN ASPF. SEE INSTALLATION AND

OPERATING INSTRUCTIONS SPECIFICALLY FOR EACH

MODEL.

Motor

Speed

Tap 0.1" 0.2" 0.3" 0.4" 0.5"

1 700 670 650 595 510

2 820 785 765 745 705

ASPF183016 3 920 900 850 840 815

4 1075 1055 1015 975 960

5 1130 1115 1085 1040 1000

1 1060 865 600 515 420

2 1105 910 795 745 690

ASPF313716 3 1165 1070 1020 960 915

4 1285 1240 1195 1140 1100

5 1435 1395 1350 1315 1265

1 1445 1275 1175 940 855

2 1545 1405 1325 1260 1145

ASPF426016 3

1660 1610 1555 1490 1415

4

1905 1870 1810 1750 1695

5

2115 2070 2000 1965 1915

CFM deliverd

against External Static Pressure

Model

Table 9