5

HIGH VOLTAGE!

Failure to do so may cause property damage,

personal injury or death.

Disconnect ALL power before servicing.

Multiple power sources may be present.

HIGH VOLTAGE!

To avoid property damage, personal injury or death

due to electrical shock, this unit MUST have an

electrical ground. The

electrical ground circuit may consist of an

appropriately sized electrical wire connecting the

ground lug in the unit control box to the building

electrical service panel.

Other methods of grounding are permitted if performed

in accordance with the National Electric Code

(NEC)/American National Standards Institute

(ANSI)/National Fire Protection Association (NFPA) 70

and local/state codes. In Canada, electrical grounding

is to be in accordance with the Canadian Electric Code

(CSA) C22.1.

uninterrupted, unbroken

Building Electrical Service Inspection

This unit is designed for single-phase electrical supply. DO

NOT OPERATE ON A THREE-PHASE POWER SUPPLY.

Measure the power supply to the unit. The supply voltage

must be in agreement with the unit nameplate power require-

ments and within the range shown in Table 5.

Nominal Input Minimum Voltage Maximum Voltage

208/240 187 253

Table 5

Wire Sizing

Wire size is important to the operation of your equipment.

Use the following check list when selecting the appropriate

wire size for your unit.

• Wire size must carry the Minimum Circuit Ampac-

ity (MCA).

• Refer to the NEC (USA) or CSA (Canada) for wire siz-

ing. The unit MCA for the air handler and the optional

electric heat kit can be found on the unit Series and

Rating Plate.

• Wire size allows for no more than a 2% voltage drop

from the building breaker/fuse panel to the unit.

Refer to the latest edition of the National Electric Code

or in Canada the Canadian Electric Code when deter-

mining the correct wire size. The following table shows

the current carrying capabilities for copper conductors

rated at 75

o

C with a 2% voltage drop. Use Table 6 to

determine the voltage drop per foot of various conduc-

tors.

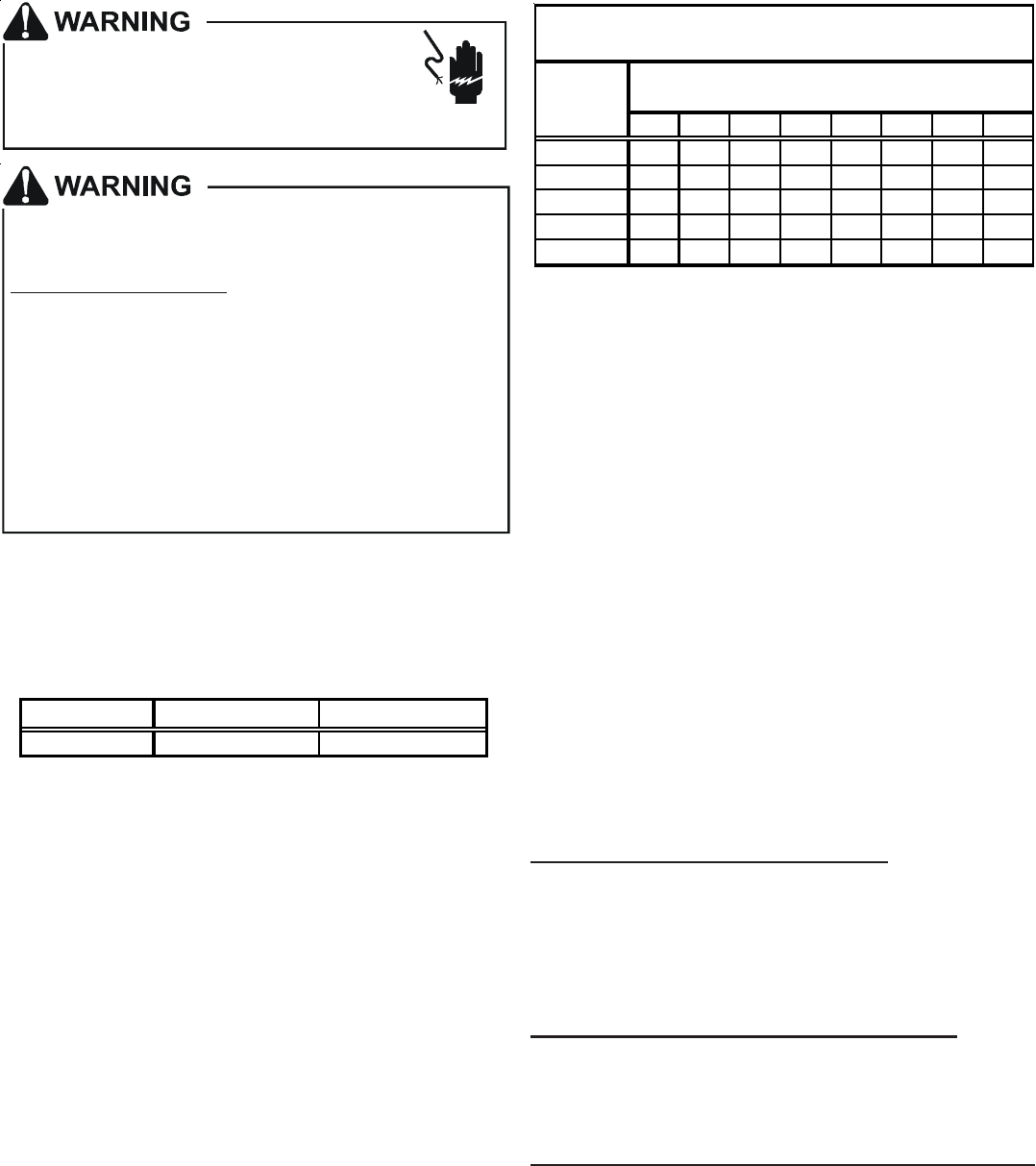

10 15 20 25 30 35 40 45

14 75 50 37 NR NR NR NR NR

12 118 79 59 47 NR NR NR NR

10 188 125 95 75 63 54 NR NR

8 301 201 150 120 100 86 75 68

6 471 314 235 188 157 134 118 110

*Based on NEC 1996

Maximum Allowable Length in Feet

to Limit Voltage Drop to 2%*

Minimum Circuit Ampacity (MCA)

Wire Size

(AWG)

Table 6

Maximum Overcurrent Protection (MOP)

Every installation must include an NEC (USA) or CEC

(Canada) approved overcurrent protection device. Also,

check with local or state codes for any special regional re-

quirements.

Protection can be in the form of fusing or HACR style circuit

breakers. The Series and Rating Plate can be used as a

guide for selecting the MAXIMUM overcurrent device.

NOTE: Fuses or circuit breakers are to be sized larger

than the equipment MCA but not to exceed the MOP.

Electrical Connections – Supply Voltage

USE COPPER CONDUCTORS ONLY.

A knockout is provided on the air handler top panel or side to

allow for the entry of the supply voltage conductors. If the

knockouts on the cabinet sides are used for electrical con-

duit, an adapter ring must be used in order to meet UL1995

safety requirements. An NEC or CEC approved strain relief

is to be used at this entry point. The wire is to be sized in

accordance with the “Electrical Wire and MOP” section of

this manual. Some areas require the supply wire to be en-

closed in conduit. Consult your local codes.

Air Handler Only (Non-Heat Kit Models)

The building supply connects to the stripped black and red

wires contained in the air handler electrical compartment cav-

ity. A ground screw is also contained in this area. Attach the

supply wires to the air handler conductors as shown in the

unit wiring diagram using appropriately sized solderless con-

nectors or other NEC or CEC approved means.

Air Handler With Non-Circuit Breaker Heat Kits

A terminal block is provided with the HKR kit to attach the

power supply and air handler connections. Follow the HKR

Installation Manual and wiring diagram for complete wiring

details.

Air Handler With Heat Kits Containing a Circuit Breaker

HKR models with a “C” suffix contain a circuit breaker(s).

The air handler has a plastic cover on the access panel that

will require either one or both sections to be removed to al-

low the heat kit circuit breaker(s) to be installed. See the

HKR Installation Instructions for further details. The air han-

dler wires and supply wires are installed directly onto the HKR

circuit breaker(s) as shown in the HKR Installation Manual

and wiring diagram.