Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

Proper maintenance is necessary to ensure

safe, troublefree operation. Inspecting the lift for

any wea

r, damage or other abnormal conditions

should be a part of your daily routine. Simple

inspections can detect potential problems.

The maintenance and lubrication procedures

specified in this schedule must be performed by

a Braun authorized service representative at the

scheduled intervals according to the number of

cycles.

The

Vangater II is equipped with hardened pins

and self-lubricating bushings to decrease wear,

provide smooth operation and extend the service

life of the lift.

When servicing the lift at the recommended inter-

vals, inspection and lubrication procedures speci-

fied in the previous sections should be repeated.

Clean the components and the surrounding area

before applying lubricants. LPS2 General

Purpose Penetrating Oil is recommended where

Light Oil is called out. Use of improper lubricants

can attract dirt or other contaminants which could

result in wear or damage to the components.

Platform components exposed to contaminants

when lowered to the ground may require extra

attention.

Lift components requiring grease are lubricated

during assembly procedures. When these com

-

ponents are replaced,

grease must be

applied during instal

-

lation procedures.

Specified lubricants

are available from

The Braun Corpora

-

tion (part numbers

provided below).

All listed inspection,

lubrication and main

-

tenance procedures

should be repeated at

“750 cycle” intervals

following the scheduled “4500 Cycles” maintenance.

These intervals are a general guideline for scheduling

maintenance procedures and will vary according to

lift use and conditions. Lifts exposed to severe condi

-

tions (weather, environment, contamination, heavy

usage, etc.) may require inspection and maintenance

procedures to be performed more often than speci-

fied.

Discontinue lift use immediately if maintenance

and lubrication procedures are not properly per-

formed, or if there is any sign of wear, damage or

improper operation. Contact your sales representa-

tive or call

The Braun Corporation at 1-800-THE LIFT.

One of our national Product Support representatives

will direct you to an authorized service technician who

will inspect your lift.

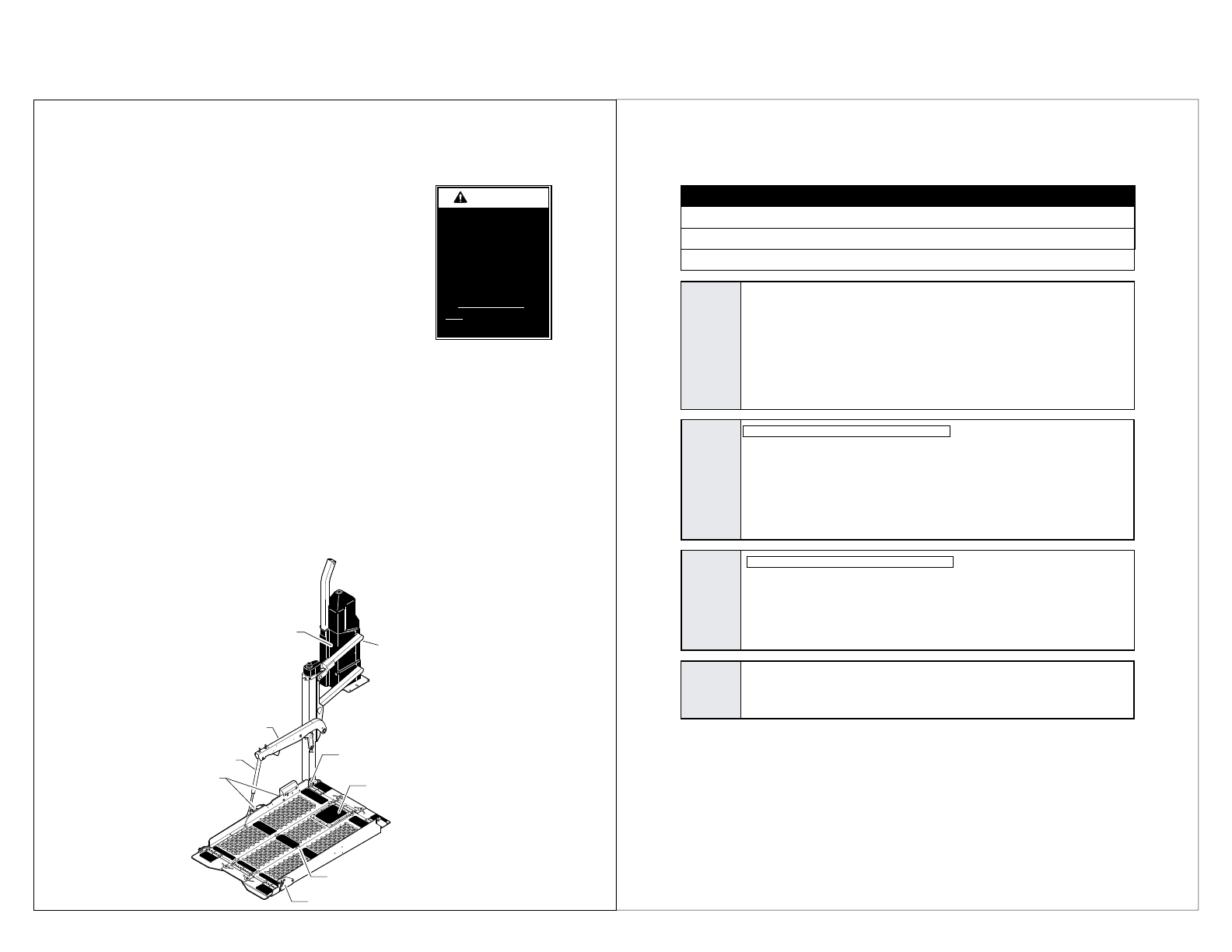

W

A

RNING

Maintenance and lu-

brication procedures

must be performed

as specified by an

authorized service

technician. Failure

to do so may result

in serious bodily

injury and/or prop

-

erty damage.

-AINTENANCEAND,UBRICATION

Switch Arm

Main Drive Ballscrew

(in Frame Tube - hidden)

Lift Rod

Downstop

(hidden)

Platform Fold

Mechanism

(Under Cover)

Inboard Locator

Latch Mechanism

Platform

Hinges (6)

Outer Barrier Latch

Drive Arms

Specified (recommended) Available Braun

Lubricant Type Lubricant Amount Part No.

Light Grease Lubriplate 14 oz.

(Multipurpose) Can

15807

15806

15805

Light Penetrating Oil LPS2, General Purpose 11 oz.

(30 weight or equivalent) Penetrating Oil Aerosol Can

Stainless Stick Door-Ease 1.68 oz.

Style (tube) Stick (tube)

#YCLES

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Grease - See Lubrication Diagram

Tighten, repair or replace if needed.

Tighten, resecure or replace if needed.

Resecure, replace damaged parts or otherwise

correct as needed. Note: Apply lubricant during

reassembly procedures.

Perform all procedures listed in previous section also

#YCLES

Apply Light Grease - See Lubrication Diagram

Add Lucas Heavy Duty Oil Stabilizer

#YCLES

Perform all procedures listed in previous sections also

Repeat all previously listed inspection, lubrica-

tion and maintenance procedures at 750 cycle

intervals.

#ONSECUTIVE

#YCLE

)NTE

RVALS

Platform fold mechanism

Ballscrew / main drive

Clean ground cable at battery and frame

Check power cables

Door-Ease

Light Oil

Light Grease

Downstop pivot points (2)

Upper lift rod pin

Lower lift rod pin

Kickout spring (located in switch arm)

Platform hinges (6)

Outboard barrier latch

Inboard locator latch mechanism

Check mounting hardware

Check all fasteners (snap rings, nuts, hairpins, etc.)

Check all pivot points for excessive wear