Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 31312

e

c

a

r

B

g

n

i

t

n

u

o

M

l

a

c

i

t

r

e

V

e

m

a

r

F

e

b

u

T

2

3ECURE,IFT

e

g

d

e

W

e

t

a

l

P

e

g

d

e

W

e

t

a

l

P

r

o

o

l

F

e

m

a

r

F

e

b

u

T

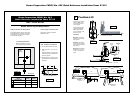

3/8-16 Hex Bolt

(Minimum 4)

• One in each corner.

• Lengths as required

per application.

5/16" Flat

Washer

3/8" Body Washer

3/8" Lock Washer

3/8-16 Hex Nut

Hardware

Typical

All Positions

Position

wedges

as needed.

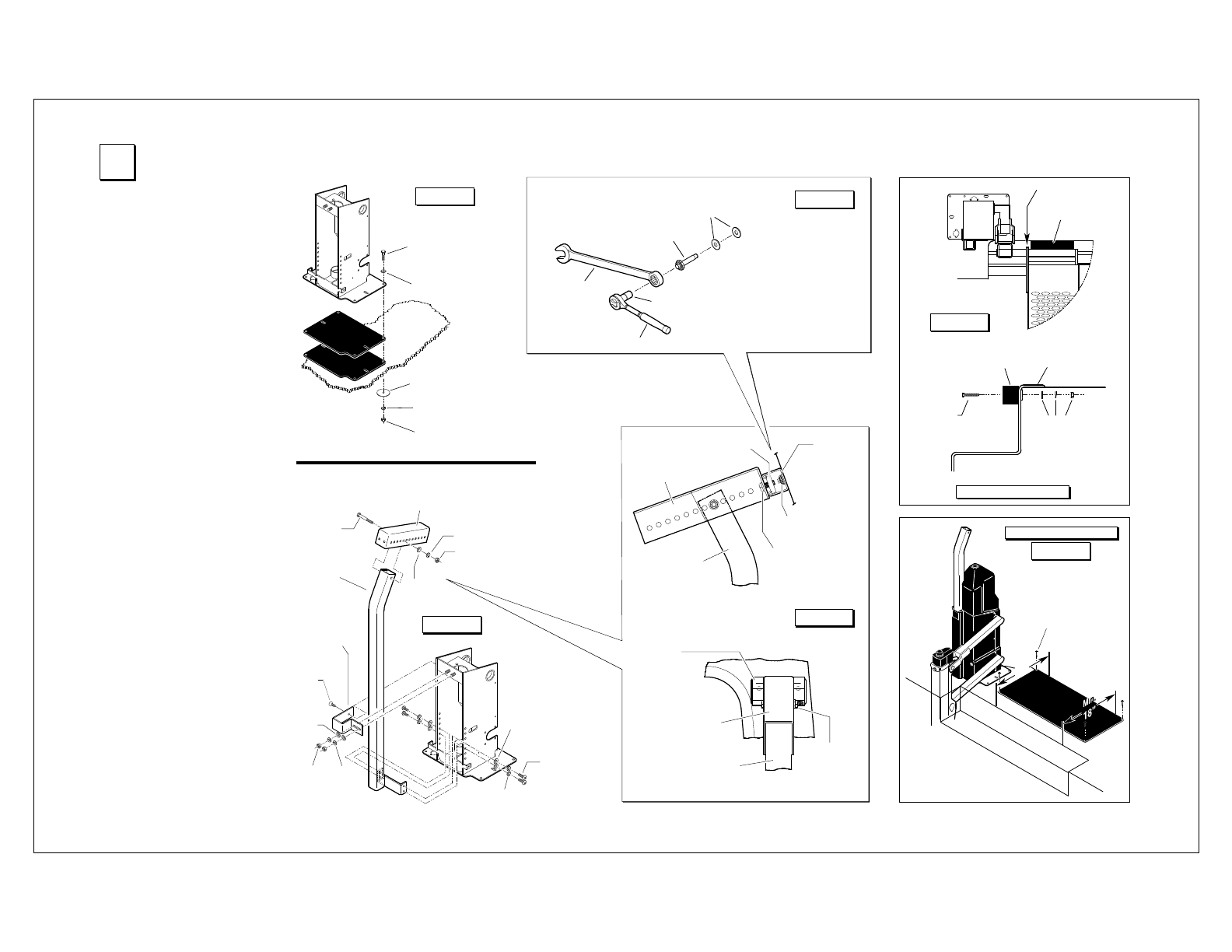

&IGURE(

Docking

Bumper

Outer Pivot

Platform

Docking

Bumper

Stepwell

Floor

Trim

5/16" Flat

Washer

3/8" Lock

Washer

3/8-16 Hex Nut

3/8-16 x 2"

Hex Bolt

(Qty: 2)

Docking Bumper

r

o

o

l

F

d

e

h

s

i

n

i

F

f

o

e

g

d

E

d

l

o

h

s

e

r

h

T

g

n

i

n

r

a

W

.

n

i

M

"

8

1

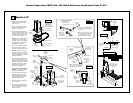

#10-16 x 1-1/2"

Wafer Head Phillips

Self-Drilling Screw

(Qty: 4)

Threshold Warning

Upper

Adjustment

Bracket

Upper

Mounting

Channel

3/8-16 x 1"

Hex Cap Screw

with

Lock

Washer

(Qty: 2)

3/8-16 Slide Nut

Vertical

Mounting

Brace

Fab-Lock Bolt

Upper

Mounting

Channel

Upper

Adjustment

Bracket

Vertical

Mounting

Brace

3/8-16 x 3"

Hex Bolt

with

Lock

Washer

and Hex Nut

Wall (C Pillar)

5/16-18 x 7/8"

Button Head

Cap Screw

Upper

Mounting

Bracket

5/16"

Hex

Nut

5/16-18 x 3/4"

Flat Head

Screw

3/8-16 x 3"

Hex Bolt

Upper

Adjustment

Bracket

3/8" Lock

Washer

3/8" Hex

Nut

5/16" Flat

Washer

5/16"

Lock

Washer

&IGURE)

5/16" Flat

Washer

5/16"

Flat

Washer

5/16" Lock

Washer

Vertical

Mounting

Brace

Fab-Lock Bolt

1/4" Flat

Washers

Ratchet Wrench

5/16" Socket

5/8" Wrench

1. Remove rubber

washer and install

1/4" flat washers.

3. Place a 5/8"

wrench onto

bolt head and

secure tightly

4. Place a 5/16" socket onto the inner

screw and tighten (turn clockwise).

5.

Turn socket until Fab-Lock has

expanded against metal surface.

Fab-Lock Bolt Installation

&IGURE*

&IGU

RE+

&IGU

RE-

&IGU

RE,

2. Insert Fab-Lock bolts (minimum

2) fully through mounting channel

and C pilla

r.

Note: Cut bracket o

ff flush with

mounting brace and install foam

padded cover using cable ties.

1. Temporarily secure base plate by

installing sheet metal screws in

base plate slots.

2. Secure vertical mounting brace

and upper mounting bracket to

frame tube. See Figure I.

3.

Temporarily assemble upper ad

-

justment bracket and upper mount

-

ing channel. See Figure K. Posi-

tion assembly and mark mounting

holes on van wall (C pillar).

Carefully drill 5/16" diameter wall

mounting holes. Secure upper

mounting channel to wall (C pillar)

using expanding Fab-Lock bolts

(minimum 2). See Figure J.

4. Secure upper adjustment bracket

and upper mounting channel as-

sembly to vertical mounting brace.

5. Carefully operate lift through all

functions checking for clearances

(specified in Figures D-I).

Adjust

lift position and/or upper mounting

hardware as needed.

6. Drill 3/8" diameter holes through

floor using the corner holes in the

base plate as a template. Refer to

Figure H. Insert 3/8"-16 hex bolts

and secure below

floor as speci-

fied in Figure H (bolt lengths as

required per application).

Tighten all mounting hardware

securely.

All fasteners must meet

FMVSS 571.403 Section 6.3.

7. Cut upper adjustment bracket off

flush with mounting brace and

install foam padded cover using

cable ties. Note: Cover power

unit before cutting bracket.

8. Position and secure docking bum

-

per. See Figure L.

9. Position and secure warning sen

-

sor mat as specified in Figure M.

Connect wiring harness to lift as

shown in Figure

P.

Hardware

typical

opposite side