SCW Series Central Chilling Stations Page 23 of 77

From Process

The chilled water return for water returning back to the chiller

from the process to be cooled and recirculated. Adjust the

butterfly valve for the pressure drop that corresponds to the model

number of the chiller. Pressure drop is equal to supply pressure

minus return pressure

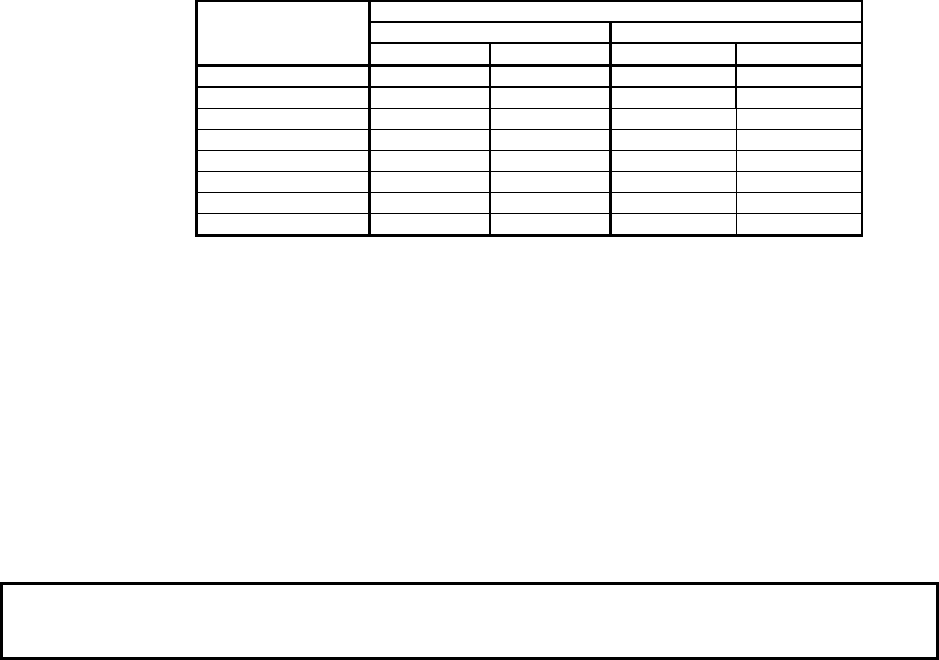

Model Water Side Pressure Drop

Condenser (each) Evaporator (each) Number

Flow (gpm) PD (psi) Flow (gpm) PD (psi)

SCWW/R60 91 4.0 72 5.3

SCWW/R75 102 4.7 90 4.5

SCWW/R90 117 4.4 107 5.6

SCWW/R100 150 5.5 123 3.9

SCWWR115 166 4.3 140 3.0

SCWW/R145 196 4.1 175 4.8

SCWW/R165 219 4.1 200 4.6

SCWW/R195 278 4.7 232 6.0

3-5 Making Tank Piping Connections

If you have purchased the SCW Series central chilling station with

the integral pump tank, please proceed with this section.

Return

Bring the chilled water returning from the process to the pump

tank warm From Process side. This line is sized according to the

flow rate from the process to the pump tank. See Section 3-3 on

Page 21 for more information on piping considerations.

Important!

Do not use the SCW Series unit to support piping.

Makeup

Connect a city water source to maintain water level in the pump

tank.

Overflow

Connect the OVERFLOW outlet to an approved, trapped drain to

permit excess water in the pump tank to overflow to the drain. The

overflow line is sized according to the size of the pump tank.

To Drain

Connect to a 1½” line (approx. 63 mm) leading to an approved,

trapped drain. You can drain the pump tank if necessary.