If you are not using a kiln vent, leave peephole plugs out

and vent the lid. Set the alarm to 1000°F. When the alarm

sounds, close the lid from venting position.

Set the alarm again, this time to 1850° F. When it sounds,

check the witness cone through the peephole. When the

cone bends to six o’clock, write down the temperature. (Use

that temperature in segment 4 on your next firing of the

sametype ofware.) Thenpress 9, ENTER(Skip Segment).

This will advance you to segment 5, a slow cooling seg

-

ment. Do not open the lid until the kiln has cooled to room

temperature.

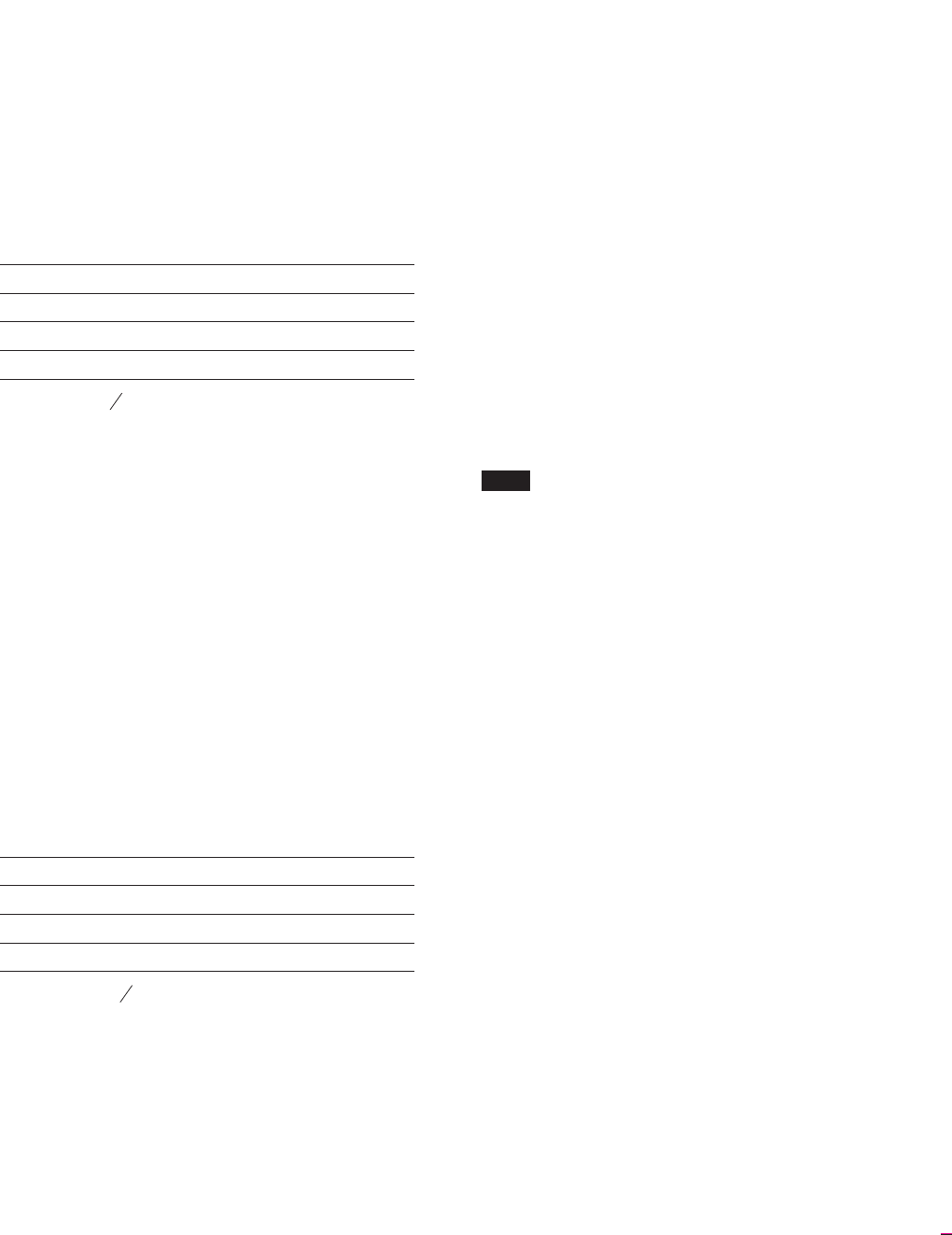

Glass Fusing Firing Schedule

Rate Temp.

Segment °F/°C °F/°C Hold

1 250/138 750/398 00.00

2 900/500 1425/773 00.30

3 9999/9999 1050/565 00.00

4 150/83 750/398 00.00

Stained glass,

1

8

", 2 layers, full fuse. The fusing tempera

-

ture will varydepending on the brand ofglass, the batch, and

even upon the color. Vent the lid. Set the alarm to 500°F.

When the alarm sounds, close the lid from venting position

and insert peephole plugs.

Set the alarm again, this time to 1350°F. When it sounds,

check the glass through the peephole. When the glass fuses

to your satisfaction, write down the temperature and hold

timefor futurefirings, andpress9, ENTER(SkipSegment).

This will advance you to segment 3, a flash cooling seg-

ment. Lift the kiln lid slightly or open the door ajar until the

temperature drops to 1050° F. Then close the door/lid. The

kiln will cool slowly through the annealing range, then turn

off.

Note: A cooling rate of 9999 (FULL) shuts off the

warning alarm that sometimes sounds during rapid

cooling.For moredetails aboutalarms,see page20.

Glass Slumping Firing Schedule

Rate Temp.

Segment °F/°C °F/°C Hold

1 250/138 750/398 00.00

2 900/500 1250/676 00.30

3 9999/9999 1050/565 00.00

4 150/83 750/398 00.00

Stained glass,

1

8

", 2 fused layers, 12" circular pieces,

slumped intoa bowl.Set the alarmto 500° F.When thealarm

sounds, close the lid from venting position and insert peep

-

hole plugs.

Set the alarm again, this time to 1150° F. When it sounds,

check the glass through the peephole. When the glass

slumps into the bowl, write down the temperature and hold

timefor futurefirings, andpress9, ENTER(SkipSegment).

This will advance you to segment 3, a flash cooling seg

-

ment. Lift the kiln lid slightly or open the door ajar until the

temperature drops to 1050° F. Then close the door/lid. The

kiln willcool slowlythrough theannealing range.Then itwill

turn off and cool to room temperature.

Note: A cooling rate of 9999 (FULL) shuts off the

warning alarm that sometimes sounds during rapid

cooling.For moredetails aboutalarms,see page20.

Starting a Firing in a Hot Kiln

Sometimes a firing begins in a hot kiln after a power fail

-

ure, or other interruption. In this case, the Sentry will begin

firing from the first segment that matches the current tem

-

perature. See Power Failures, page 23.

When the Kiln Shuts Off Too Soon

Ceramic Firings

If the kiln fires to completion before the pyrometric wit

-

ness cone bends, you can turn the kiln back on and keep fir

-

ing. Simply program a hotter temperature. Then from

IdLE , press START. The kiln will begin firing, taking up

where it left off.

Note: By looking at the witness cones through a

peephole,you willknow ifthekiln shutsofftoo soon.

Ifthe kilnshuts offwithin100°F/55°C ofmaturity, andthe

temperature drops 50°F/28°C or more after the kiln shuts

off, do not depend on the witness cones. Once they cool

50°F/28°C after they have been heated to within 100°F/55°C

of maturity, theywill not bend properly. Thisis because they

form a hard shell.

Wrong Thermocouple Type

If a Type-K thermocouple is installed on your kiln, but

your controller is set for Type-S, the kiln will continually

underfire by a wide margin. See page 19 to check thermo

-

couple type.

15