TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 18 -

MAINTEN

MAINTEN

ANCE SCHEDULE

ANCE SCHEDULE

To ensure the optimal safety and reliability of your power positioning system, please adhere to the mainte-

nance schedule/table below. In addition to the maintenance schedule, please note the following mainte-

nance tasks that should be incorporated into your daily routine.

Daily

Check that the buttons or toggles that operate your TRx system function freely

Charge batteries (refer to the information provided in this chapter and to your powerbase Owners

Manual for details on battery charging & battery care)

To ensure your power positioning system is operating properly and safely, Motion Concepts recom-

mends a complete Dealer inspection be performed on your power positioning system every 6 months.

*Please refer to the Powerbase Owners Manual for maintenance information specific to your powerbase*

9.0

General

Maintenance

&

Safety

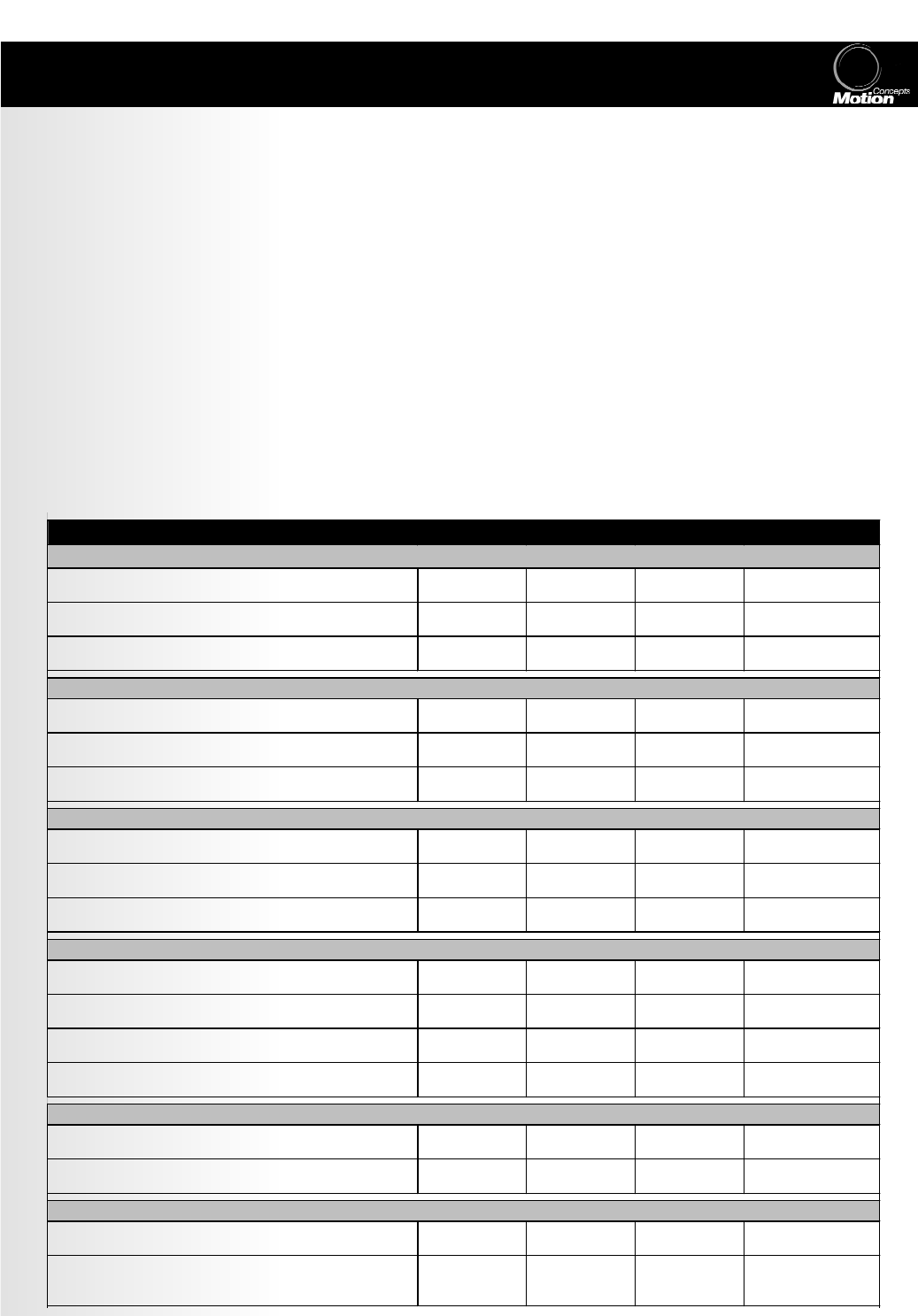

Item Initially Monthly 6 Months Periodically

load test batteries (individually) -see Battery Testing p.20 XX

ensure batteries are clean (free from corrosion/ moisture/

dirt)

XX

ensure connections are tight and clean XX

check for pinches or pulls in w iring (over full range of

seating system)

XX

inspect for w ear & tear damage to w ires XX

ensure connections are secure XX

ensure actuator rod ends are secure and pinned properly XX

ensure no interference/ sticking during system operation

(over full range of seating system)

XX

inspect for excessive noise or grinding XX

ensure that the anti-tipper latch system functions properly

(if applicable)

XX

mounting hardw are (seating system to pow erbase) XX

ensure all nuts and bolts are secure XX

inspect that all pivot points are operating smoothly & freely

and secured (do not overtighten)

XX

check all limit sw itch settings XX

ensure DLO functions correctly XX

ensure channel is free from dirt/ dust/ grime XX

as needed, lightly lubricate slide channel using a non-

lithium/ non-aerosol cleaner (eg. AGS- Sil Glyde Brake

Lubricant)

X

Limit Switches

Glide Blocks and Track Maintenance

Actuators (where applicable)

Tightening & Adjustment (hardware)

Batteries

Electrical / Wiring Harnesses

SAFETY INSPECTION CHECKLIST

SAFETY INSPECTION CHECKLIST