4 Form 10590149-Edition 2

Routine Inspection

The type of application for a hoist varies so greatly it is

impractical to recommend an exact time-table for inspection

of the hoist. Where hoist is subjected to continuous operation

with capacity loads, it is recommended the unit be inspected

twice a week. If the application is less demanding, the unit

should be inspected twice a month. In general, the frequency

of inspection should be determined by the severity of the

application. The user of a hoist should be guided by any

existing federal, state or local regulations governing the use,

testing or inspection of the hoist.

If any damage or malfunction is evident do not operate hoist

until all repairs have been made and hoist tested for proper

operation.

The following points and areas are recommended for

inspection:

Load Chain and Anchor Points

• Visually check for nicked, gouged, twisted, bent,

corroded, rusted, worn or broken links. Check ends of

chain where chain is anchored to hoist frame and where

chain is fastened to lower hook. Check anchors and pins

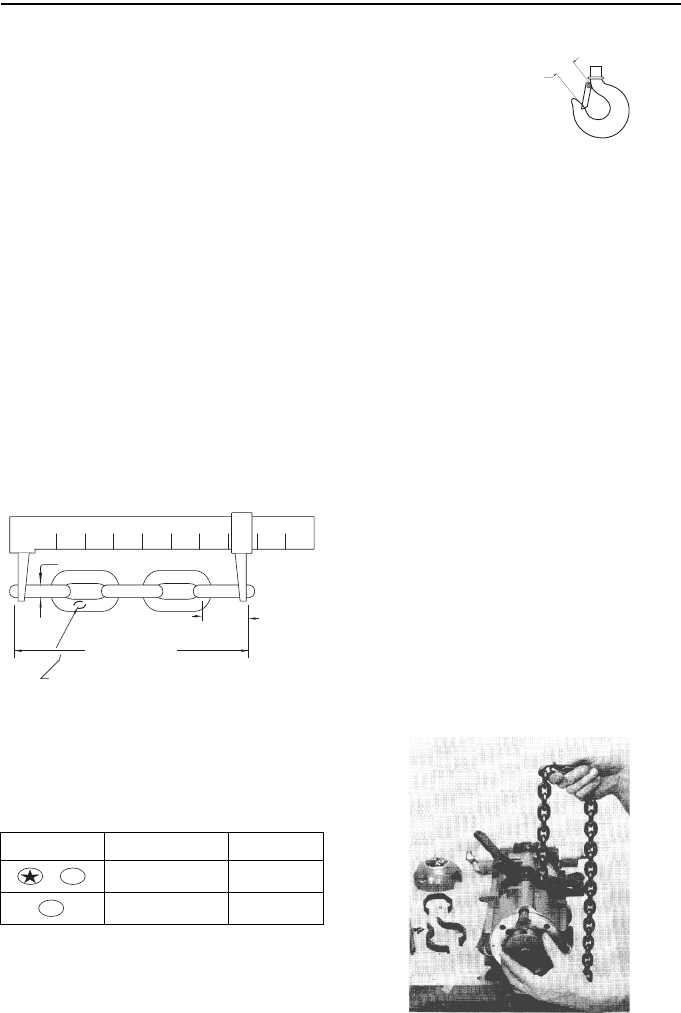

• Check chain elongation with a vernier caliper as shown.

IF VISUAL CHECK REVEALS NO DEFECTS,

PROCEED AS FOLLOWS:

LAY USED CHAIN ON FLAT SURFACE AND MEASURE

BETWEEN FIVE (5) LINKS AS SHOWN.

MEASUREMENT SHOULD BE TAKEN ON PORTION

OF CHAIN WHICH HAS MOST PASSED OVER THE

POCKET WHEEL.

IF MEASUREMENT TAKEN IS (SEE TABLE) INCHES

OR MORE, CHAIN SHOULD BE REPLACED.

IT IS NOT INFERRED that a chain is safe prior to the

occurence of elongation of the chain. It is inferred ONLY, that

when said elongation is evident, the chain must be replaced.

Other factors, such as those mentioned as a visual check,

may render chain unsafe long before replacement due to

elongation is necessary. NOTE: New chain should never be

used on a worn pocketwheel, replace chain and pocketwheel

as a pair. Chain should also be replaced when replacing

brake shoes.

Hooks and Suspension

• Check upper and lower hooks and related parts for bent,

worn, cracked, broken or otherwise damaged parts.

• On trolley suspended models, check conditions of trolley

parts, trolley adapter and related parts.

• Check for loose bolts, nuts, or rivets.

Brake

1. Check brake operation - see Adjusting Brake, page 2.

2. Check brake linings and components. NOTE: When

replacement of brake shoes is indicated, they must be

replaced as a pair. Also replace chain at this time.

Gears, Bearings and Pocketwheel

• Check teeth on gears and motor shaft pinion.

• Check pockets of pocketwheel.

• Check bearings for noisy operation indicating wear.

Throttle Valve Head and Gears

• Check valve body, valves, and “O” rings on valves.

• Check gear teeth and bearings.

Air Motor

• Check end faces of rotor for roughness and blade slots

for wear or burrs. A new blade should slide in and out of

slots without binding.

• Check blades for wear, warpage or other damage.

• Check cylinder bore diameter for rough circular grooves

from scoring. A badly scored cylinder cannot be restored

by honing since it will only enlarge bore diameter,

widening seal point between rotor and cylinder, hindering

free exhaust of air and result in loss of speed and power.

• Check end plates for wear or scoring. Check bearings.

• Follow all operating and routine inspection procedures

prescribed in this manual.

• Disconnect air supply from hoist before performing

maintenance or service procedures.

• Never apply excessive pressure by a holding device

which may cause distortion of a port.

• Apply pressure evenly to parts which have a press fit.

• Apply even pressure to the bearing race that will be press

fitted to the mating part.

• Use correct tools and fixtures when servicing this tool.

• Don’t damage “O” rings when servicing tool.

• Use only genuine ARO replacement parts for this tool.

When ordering specify part number, description, tool

model number and serial number.

IDENTIFICATIONS

MARKINGS

NEW CHAIN

MEASUREMENT

REPLACE CHAIN

4.291 4.366

4.340 4.415

5/16

VERNIER CALIPER

NEW CHAIN

.8583 PITCH

DETERMINE TYPE OF IDENTIFICATION MARKINGS EMBOSED ON LOAD CHAIN

AND FIND DIMENSIONS IN TABLE

or

ARO

OC

R

CORRECT

HOOK OPENING

1-1/4" ON 1-TON UPPER & LOWER HOOKS

1-3/8" ON 2-TON UPPER & LOWER HOOKS