2 Form 10590149-Edition 2

Safety Information

Operating Precautions

To aid the operator’s understanding of proper and safe use of

hoists, the publication “OVERHEAD HOISTS”,

ANSI B30.16-1981, can be purchased from:

American Standards Institute, Inc.

1430 Broadway

New York, New York 10018

• Do not use the hoist described in this manual to lift or

transport humans.

• Never try to lift a load heavier than the rated capacity of

the hoist.

• Operate hoist with caution. Operator should have a good

attitude toward safety.

• Always follow “proper operating” instructions given in this

manual.

• Allow only people who have received training in “proper

hoist operation” to operate hoists.

• Follow all operating and routine inspection procedures

prescribed in this manual.

• Operator of hoist shall operate hoist in a position that will

not be hazardous to his health.

• Do not attempt to operate hoist if it is not operating

properly.

• Before operating hoist, all routine inspection and

lubrication procedures should be completed.

Lubrication

Routine Lubrication Requirements

Lack of or an excessive amount of lubrication will affect the

performance and life of this tool Use only recommended

lubricants at below time intervals:

EVERY 8 HOURS OF TOOL OPERATION -fill lubricator

reservoir with spindle oil (29665). If an in line or air line

lubricator is not used, fill oil reservoir of built-in oiler of hoist

head.

EVERY 80 HOURS OF HOIST OPERATION - Grease fittings

in lower BLOCK HOOK ASSEMBLY and TROLLEY

WHEELS with NLGI #1 grease 33153).

EVERY 160 HOURS OF HOIST OPERATION - Fill oil

reservoir in GEAR CHAMBER with “EP” gear oil (40164).

Coat load chain of hoist with EP” gear oil (40164).

Air Supply Requirements

For maximum operating efficiency, the following air supply

specifications should be maintained to this hoist.:

• AIR PRESSURE - 90 PSIG (6 bar)

• AIR FILTRATION - 50 micron

• LUBRICATED AIR SUPPLY

• HOSE SIZE - l/2” (13 mm) I.D.

An AR0 model 128241-800 airline FILTER/REGULATOR/

LUBRICATOR (F-R-L) is recommended to maintain the

above air supply specifications.

Recommended Lubricants

After disassembly is complete all parts, except sealed or

shielded bearings, should be washed with solvent. To

relubricate parts, or for routine lubrication, use the following

recommended lubricants:

Operation

Suspending Hoist Adjusting Brake

Always select an overhead support capable of supporting

combined weight of hoist, trolley, and hoist’s load capacity.

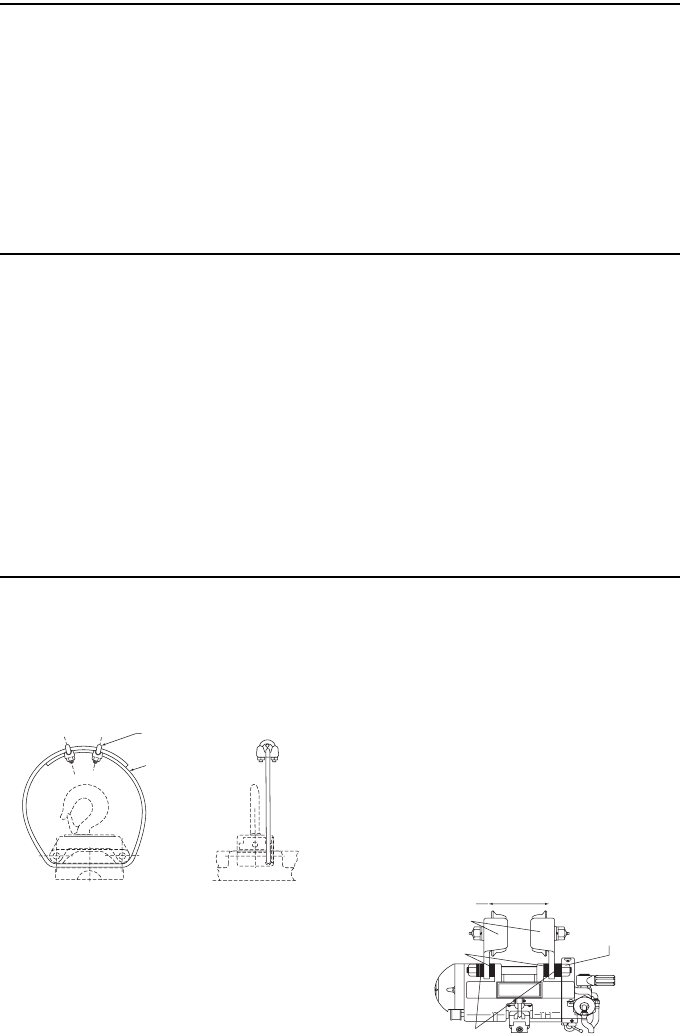

Hook Suspended Models

• Upper hook should be firmly seated in center of hook

saddle and that safety latch is closed.

• 43059 secondary support cable is recommended.

(Dwg. )

Trolley Suspended Models

• Be sure TROLLEY WHEELS are compatible with beam

being used.

• Width between outside of TROLLEY WHEELS should be

the width of beam flange + l/2”.

• If 43111 - 90’ ADAPTER is used, mount to hoist before

attempting to install trolley.

• Width is varied by using SPACERS between the hoist

body and the trolley SIDE PLATES.

• Insert an equal number of SPACERS on each inside of

the trolley SIDE PLATES until beam flange + l/2”

measurement is reached. SIDE PLATES must be

vertical.

• Insert SHAFTS (43009) through hoist, or adapter if used,

and trolley SIDE PLATES.

• Position trolley and hoist assembly on beam.

• Put an equal number of SPACERS on each end of

SHAFTS (43009) with lock washer being last.

• Tighten nuts on SHAFTS (43009). SHAFTS should

extend all the way through the NUTS.

• Move trolley over entire length of beam. If it appears the

trolley SIDE PLATES can be moved closer together and

freedom of movement will be maintained, remove an

equal number of SPACERS from inside the SIDE

PLATES and assemble these SPACERS to the outside of

the SIDE PLATES.

• Tighten NUTS to 25-30 ft. Ibs.

• Connect sufficient length of air hose to reach the

maximum travel distance of trolley.

Where Used ARO Part# Description

Air Motor 29665 1 qt. Spindle Oil

Gears and Bearings 33153 5 lb. “EP” - NLGI #l1Grease

“O” Rings & Lip Seals 36460 4 oz. Stringy Lubricant

Gearing Oil Chamber 40164 1 qt. “EP” Gear Oil

42631 CLAMP (2)

43066 RESTRAIN-

ING CABLE (5/16”

DIA. X 3½ FT. LONG

AIRCRAFT CABLE)

EQUAL NO. OF SPACERS

EQUAL NO. OF SPACERS

WIDTH OF BEAM

FLANGE PLUS 1/2”

TIGHTEN NUTS 46049

25 TO 30 FT. LBS. TORQUE

SIDE PLATES MUST

BE VERTICAL