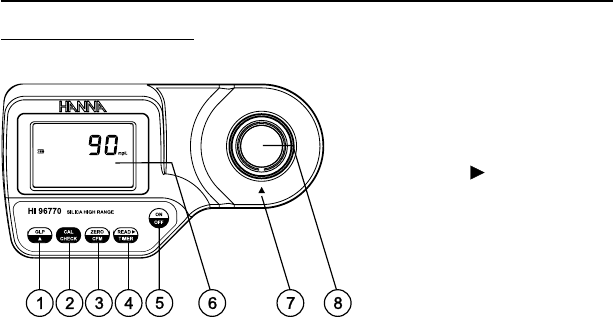

7

1) GLP/

V

key

2) CAL CHECK key

3) ZERO/CFM key

4) READ

/TIMER key

5) ON/OFF key

6) Liquid Cristal Display (LCD)

7) Cuvet alignment indicator

8) Cuvet holder

A microprocessor controlled LED emits radiation which is first optically conditioned and beamed to the

sample contained in the cuvet. The optical path is fixed by the diameter of the cuvet. Then the light is

spectrally filtered to a narrow spectral bandwidth, to obtain a light beam of intensity I

o

or I.

The photoelectric cell collects the radiation I that is not absorbed by the sample and converts it into

an electric current, producing a potential in the mV range.

The microprocessor uses this potential to convert the incoming value into the desired measuring unit

and to display it on the LCD.

The measurement process is carried out in two phases: first the meter is zeroed and then the actual

measurement is performed.

The cuvet has a very important role because it is an optical element and thus requires particular

attention. It is important that both, the measurement and the calibration (zeroing) cuvets, are optically

identical to provide the same measurement conditions. Whenever possible use the same cuvet for

both. It is necessary that the surface of the cuvet is clean and not scratched. This to avoid measurement

interference due to unwanted reflection and absorption of light. It is recommended not to touch the

cuvet walls with hands.

Furthermore, in order to maintain the same conditions during the zeroing and the measuring phases,

it is necessary to close the cuvet to prevent any contamination.

INSTRUMENT DESCRIPTION

FUNCTIONAL DESCRIPTION