Rebuild

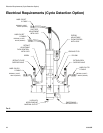

332089B 21

Build the Divorced Section and Mount to the Main

Body

5. Place lubricated U-cup Seal (8) lip side up into the

Divorced Section (10). Place the Washer (7) over it,

and reinstall the Retaining Ring (6).

6. Lubricate and insert the Metering Rod (11) into the

Divorced Section (10) from the bottom and push up

carefully through the U-cup seal (8).

7. Install the Seal Cup (12) into the Divorced Section

(10) over the Metering Rod (11) and slide the lubri-

cated Posipak Seal (13) over the Metering Rod

keeping the O-ring side of the Posipak facing down.

The ends of the Metering Rod (11) should be pro-

jecting from the upper and lower ends of the

Divorced Section.

8. Lubricate the dispense sleeve bore in the Main

Body (27). Insert the Dispense Sleeve (14) into the

Main Body (27). Check for threads that may be in

the inside of the sleeve due to tapping during

removal and make sure these are at the top.

9. Install a lubricated O-ring (15) around the Dispense

Sleeve (14).

10. Holding the Divorced Section (10) and using the

projecting Metering Rod (11) as a guide slide the

Metering Rod (11) into the Dispense Sleeve (14)

and install the Divorced Section (10) against the

Main Body (27). Install the Screws (16).

Mount the Valve End Caps to the Seal Plate Cups

11. Install a lubricated U-cup Seal (4) onto the left Spool

Shift Piston (21) with lip side out as shown. Lubri-

cate the bore in the End Cap (19). Slide the piston

into the left End Cap (19) tucking the lip of the seal

into the End Cap carefully.

12. Install the Piston/End Cap onto the left Seal Plate

Cup (26) using four Screws (18). Tighten the screws

in a cross patter n gradually to prevent binding due

to misalignment (like you would tighten lug nuts on a

car tire).

13. Push the Spool into the left side until it contacts the

piston.

14. Repeat steps 13 and 14 for the right side.

Install the Drive Cylinder

15. Install lubricated O-ring (5) on top of the Divorced

Section (10).

16. Install two lubricated U-cup Seals (4) onto the Dis-

pense Piston (3) with the upper seal lip up and the

lower seal lip down as shown.

17. Lubricate the bore of the Drive Cylinder End Cap

Assembly (2) and insert the Dispense Piston (3)

flush with the end of it, tucking the lip of the upper

U-cup Seal (4) so that it is not damaged.

18. Slide the Metering Rod (11) into the key slot on the

piston and slide the Drive Cylinder End Cap Assem-

bly (2) down onto the Divorced Section (10) and

carefully over the O-ring (5).

19. Align the screw holes in the Drive Cylinder End Cap

Assembly (2) with the corresponding holes in the

Divorced Section (10) and install the four Screws

(1). Tighten the screws in a cross pattern gradually

to prevent binding due to misalignment (like you

would tighten lug nuts on a car tire).

20. Install the short air lines on the left and right sides of

the valve.

Install the Needle Block Assembly

21. Install any removable needles that were previously

removed.

22. If your valve has cycle detection, slide the cycle

detection sensors into the slots on the end caps and

secure with the set screws. Do not overtighten the

set screws as the sensors may be damaged.

23. Connect the air lines.

24. Perform the Dry Run, Loading & Priming and Output

Verification procedures. Perform Operation Adjust-

ment procedures if required.