1

•

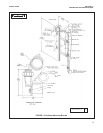

LARGE ELECTROLYTE RESERVOIR allows up to twelve months and often longer

between refills.

•

OPTIONAL MOUNTING BRACKET allows easy removal of the sensor from an aeration

basin without the use of tools.

•

MODULAR PRESSURE COMPENSATOR AND MEMBRANE RETAINER simplify recharg-

ing and membrane replacement.

• MEMBRANE RETAINER REPLACEMENT AND RECHARGING require no tools.

MODEL 430 DO SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0

GENERAL DESCRIPTION AND SPECIFICATIONS

1.1 FEATURES AND APPLICATIONS

The Rosemount Analytical

®

Model 430 Dissolved

Oxygen Sensor, used with the Model 1181 Dissolved

Oxygen Transmitter, measures oxygen levels in a vari-

ety of applications. The most widely used application is

the secondary phase of the waste treatment process

where a critical dissolved oxygen level must be main-

tained for the digestive process to occur. Other appli-

cations include water quality monitoring in natural bod-

ies of water such as rivers and streams, or any location

where adequate oxygen content is important to sustain

aquatic life.

The Model 430 Dissolved Oxygen Sensor is construct-

ed of PVC with an oxygen permeable Teflon

1

mem-

brane .

1.2 OPERATION

As oxygen passes through the Teflon membrane an

oxygen dependent electrochemical reaction takes

place between the gold cathode and silver anode in the

presence of the electrolyte. The resultant current flow

between these elements is proportional to the quantity

of oxygen which has entered the sensor.

Temperature and pressure compensation are both

standard features on the Model 430. Temperature com-

pensation is necessary for two reasons: First, the solu-

bility of oxygen in water decreases with an increase in

temperature; secondly, the permeability of the Teflon

membrane and the oxygen diffusion rate increase as

the temperature increases. For these reasons, it is

important for a dissolved oxygen measurement to be

accompanied by an accurate temperature measure-

ment. Temperature compensation is accomplished by

means of a thermistor located in the sensor housing,

and its associated circuitry in the analyzer.

Pressure compensation is a mechanical rather than

electronic correction. It is important for the tension on

the Teflon membrane to remain constant at all times,

even with sample pressure changes. Fluctuations in

membrane tension affect its diffusion characteristics.

By means of a pressure compensator the pressure on

the sample side of the compensator membrane is

transmitted to the electrolyte reservoir so the pressure

on both sides of the membrane remains equal. In this

manner, sample pressure changes do not affect the dif-

fusion rate of oxygen through the membrane.

The Teflon membrane is held in place by a retainer. A

water-tight seal is made with an O-ring between the

membrane and sensor reservoir. Membrane replace-

ment is rarely required, but in those situations when it

is necessary, the procedure can be performed quickly

and easily.

Since oxygen diffuses through the Teflon membrane at

a faster rate than through the sample, it is necessary to

continuously maintain a fresh sample in front of the

membrane. A stream velocity of approximately 1.5 feet

per second (0.5 m/s) is required to ensure that a fresh

sample is in contact with the membrane at all times.

1

Reg. U.S. Pat. Office for du Pont’s fluorocarbon resins.