10

4.1 GENERAL. This section contains troubleshooting

data for the Model 430 Sensor Assembly.

4.2 TROUBLESHOOTING THE MODEL 430

DISSOLVED OXYGEN SENSOR. The majority of

problems encountered in DO systems are because the

sensor is either improperly maintained or has an inter-

nal leakage causing improper temperature compen-

sator resistance and high impedance current paths

between elements of the sensor.

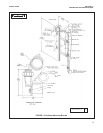

Disassemble the sensor completely by unscrewing the

reservoir retainer and pulling the reservoir housing

assembly straight out (refer to Figure 5-2). The mem-

brane may have dried onto the gold cathode. Soak this

loose with water as scraping will damage the gold tip.

Clean all the parts with clean water and dry them.

Check for visible damage (i.e., cracks, deep cuts, bro-

ken silver wires). Perform the following checks with an

ohmmeter. Check T.C. resistance between the green

and white wires. It should be 100K ohms at 25°C or per

the Temperature/Resistance Chart. Check continuity

between the red wire and the silver anode, and

between the black wire and the gold cathode (be care-

ful not to scratch the gold). Perform a high meg check

between the following (100 meg ohms minimum):

Shield to Black or Red or Green. If everything checks

O.K., the sensor should function after a proper

recharge. If the silver anode appears oxidized, it may

be cleaned with wet or dry 400 sandpaper. Also brush

the gold tip two or three times with the 400 sandpaper

in one direction only. Follow the recharge directions in

Section 3.2.

4.3 BENCH TESTING. Soak the electrode for 24 hours

with polarizing voltage applied (instrument), then air

calibrate to check for a response.

CAUTION

Care should be taken not to damage the

membrane made of “Teflon”.

1. Low readings and inability to calibrate are

generally the result of a coated membrane

and usually can be restored to service by

cleaning the sensor. Clean a coated mem-

brane by gently wiping the membrane with a

soft cloth or tissue.

1

Reg. U.S. Pat. Office for du Pont’s fluorocarbon resins.

2. Readings offscale and inability to calibrate

are usually caused by a damaged mem-

brane. If this is the case, replace the mem-

brane.

3. To check the membrane made of “Teflon”,

connect the negative (—) lead of an ohm-

meter to the cathode (black) lead and

place water saturated with salt on the

membrane. Touch the positive (+) lead to

the water. The meter should read open

(100 megohms or more). If the meter indi-

cates a short (less than 100 megohms),

replace the membrane (refer to Section

3.2).

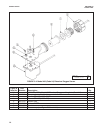

4. To check the resistance of the temperature

compensator, connect an ohmmeter to the

green and white leads of the sensor. The

resistance should be as indicated at the

temperature listed below: If the resistance

as specified above cannot be achieved,

replace the sensor (Figure 5-2).

Temperature Resistance Chart

5. To check for shorted sensor leads, meas-

ure the resistance between one tempera-

ture compensator wire (green or white) and

the cathode (black) lead and anode (red)

lead. The meter should indicate an open

circuit (100 megohms or more). Repeat the

measurement using the other temperature

compensator wire. If the sensor shows a

short circuit, the sensor is defective and

should be replaced.

MODEL 430 DO SECTION 4.0

TROUBLESHOOTING

SECTION 4.0

TROUBLESHOOTING

TEMPERATURE RESISTANCE (ohms)

0°C 371.40K

10°C 214.50K

20°C 128 00K

25°C 100.00K

30°C 78.00K

40°C 49.80K

50°C 32.36K