5

Chapter 1

Introduction

Description

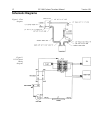

The Model CC-100 Coolant Circulator is a universal water-to-air heat exchanger. It

transfers heat from any heat source into the air. It was designed primarily for removing

heat from thermoelectrically cooled CCD cameras. A magnetic drive coolant pump

circulates coolant to the CCD camera (or any other heat source). This coolant passes

through the hot side of the camera, which raises the temperature of the coolant. The

heated coolant is then returned to the radiator of the CC-100. An internal fan forces air

through the radiator reducing the temperature of the coolant by convection. The coolant

then returns to the pump and repeats the cycle. This efficient closed cycle process can

maintain the temperature of the coolant within a few degrees above ambient temperature.

Specifications

Note:

All test data and specifications shown are based on pumping water and are

guidelines only. Specifications will vary depending on specific fluid, temperatures, and

other operating conditions.

Coolant:

Water, water/ethylene glycol (50% solution), automotive antifreeze and other

inert liquids with viscosity approximately that of water.

Capacity:

Approximately 0.9 quart ( 0.85 liter), exclusive of external coolant lines and

device to be cooled.

Pressure and Flow

Maximum head pressure 13 feet (4 meters), 6.38 PSI ( 44 kPa), with zero

flow.

Maximum flow is 5 gallons per minute (19 liters/min) with zero head pressure.

A flow rate of 1 gallon per minute (3.8 liters/min at 5 PSI (34.5 kPa).

In a typical application with 20 feet (6 meters) of 3/16 (4.76 mm) I.D. polyurethane

tube, and 8 Swagelock quick connect connectors. The flow rate will be 1 pint per

minute ( 0.5 liters/min).

In a typical application with 20 feet (6 meters) of 3/16 (4.78mm) I.D. polyurethane tube

with only tube connectors. The flow rate will be 1 quart per minute ( 0.95 l/min).