14

SAFETY INSPECTION

WARNING

DO NOT use the wheelchair unless it has the

proper tire pressure (p.s.i.). DO NOT over-inflate

the tires. Failure to follow these suggestions may

cause the tire to explode and cause bodily harm.

5. Inflate tires to the recommended tire pressure listed

on the side wall of the tire.

6. The wheels and tires should be checked periodi-

cally for cracks and wear. If damaged, have them

replaced by a qualified technician.

7. Regularly check for loose spokes in the rear wheels.

If loose, have them adjusted by a qualified techni-

cian.

8. Periodically check handrims to ensure they are se-

cured to the rear wheels. Refer to

HANDRIM RE-

PLACEMENT in PROCEDURE 5 of this manual.

9. Periodically adjust wheel locks in correlation to tire

wear. Refer to

WHEEL LOCK ADJUSTMENT/RE-

PLACEMENT in PROCEDURE 5 of this manual.

10. Periodically check caster wheel bearings to make

sure they are clean and free from moisture. Use a

Teflon

®

lubricant if necessary.

11. Check Upholstery for sagging, rips or tears.

12. A-6S AND F-6S ONLY - Check elastomers for wear

and/or damage. If wear or damage is found, replace

elastomers.

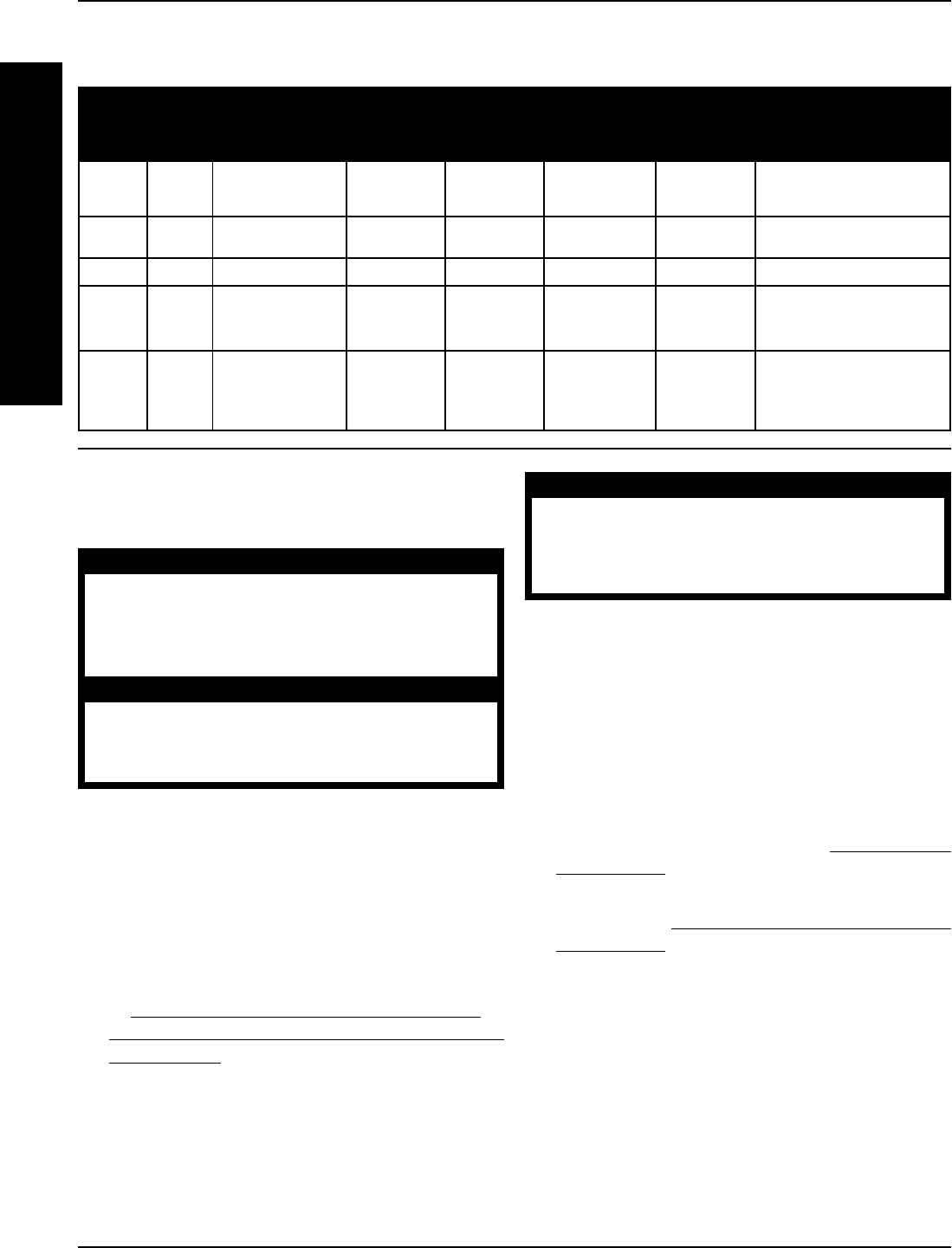

CHAIR CHAIR SLUGGISH CASTER SQUEAKS LOOSENESS CHAIR SOLUTIONS

VEERS VEERS TURN OR FLUTTERS AND IN CHAIR 3 WHEELS

RIGHT LEFT PERFORMANCE RATTLES

XX X X XCheck tires for correct

and equal pressure.

XXXX Check for loose stem

nuts.

XX Check spokes/nipples.

XX X XCheck washers above

and below bearings in

headtube (Procedure 3).

XX X Check that rear wheels

are equally spaced away

from seat frame

(Procedure 3).

TROUBLESHOOTING

MAINTENANCE

Maintenance Safety Precautions

WARNING

After ANY adjustments, repair or service and BE-

FORE use, make sure all attachment hardware is

tightened securely - otherwise, injury or damage

may result.

CAUTION

DO NOT overtighten hardware attaching to the

frame. This could cause damage to the frame

tubing.

Suggested Maintenance Procedures

1. Before using your wheelchair, make sure all nuts

and bolts are tight. Check all parts for damage or

wear and replace. Check all parts for proper adjust-

ment.

2. Keep quick/quad-release axles free of dirt and lint to

ensure positive locking and proper operation. Refer

to

ADJUSTING THE QUICK-RELEASE AXLE or

ADJUSTING THE QUAD-RELEASE HANDLE IN

AND/OR OUT in PROCEDURE 5 of this manual.

3. Oil quick-release axles at least once (1) a month

(3-in-1 oil

®

or equivalent).

4. Keep optional quick release levers on axle tubes free

of dirt and lint to ensure positive locking and proper

operation.

PROCEDURE 2

I

N

S

P

E

C

T

I

O

N

S

A

F

E

T

Y

3-in-1 oil - Registered trademark of American Home Products Corportaion.

Teflon - Registered trademark of E. I. Du Pont De Nemours and Company