Rev. 0508

3

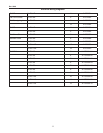

Cut and Plan Views

45 13/16"

45"

34 1/8"

11 7/8"

35"

11 5/16"

17 1/8"

8"

9 3/4"

24 3/8"

15 7/8"

27 3/4"

6 7/8"

11"

29 3/8"

4 3/8"

Q1-DC

Single Deck Deli - Curved Glass

Scale = 1/2"

44 7/

1

6"

"

5

4

21

1/8"

39 1/

8"

55 1/2

"

4

5

/8

"

45° I/S

4'

STRAIGHT

45° O/S

48"

DRAIN

DRAIN

DRAIN

REF.

DROP

REF.

DROP

REF

.

DROP

14

"

6 1/8"

Drain 5" from

Center LIne

/

1

7

1

8"

6 1/4"

16 1/2"

13

1/8"

1

2

1

/8

"

4 3/8"

9 1/2"

13

3

/8"

28

"

Plan View

Straight plan view with

Inside and Outside Wedges

Scale = 1/2"

C

L

Installation

Location

The refrigerated merchandisers have been designed for

use only in air conditioned stores where temperature and

humidity are maintained at or below 75°F and 55% relative

humidity. DO NOT allow air conditioning, electric fans, ovens,

open doors or windows (etc.) to create air currents around

the merchandiser, as this will impair its correct operation.

Product temperature should always be maintained at a

constant and proper temperature. This means that from the

time the product is received, through storage, preparation

and display, the temperature of the product must be

controlled to maximize life of the product.

Uncrating the Stand

Place the xture as close to its permanent position as

possible. Keep in place, attached case until ready to set/bolt

to adjoining case.

Tighten Glass Screws

Tighten screws along clamshell located on the underside

of glass before placing unit into operation.

Exterior Loading

These models have not been structurally designed to

support excessive external loading. Do not walk on their

tops; This could cause serious personal injury and damage

to the xture.

Setting and Joining

The sectional construction of these models enable them to be

joined in line to give the effect of one continuous display.

An Alignment pin kit is supplied with every case and must

be used in alignment.

Leveling

IMPORTANT! IT IS IMPERATIVE THAT CASES BE

LEVELED FROM FRONT TO BACK AND SIDE TO SIDE

PRIOR TO JOINING. A LEVEL CASE IS NECESSARY

TO INSURE PROPER OPERATION, WATER DRAINAGE,

GLASS ALIGNMENT, AND OPERATION OF THE HINGES

SUPPORTING THE GLASS. LEVELING THE CASE

CORRECTLY WILL SOLVE ALL HINGE OPERATION

AND GLASS PROBLEMS.

NOTE: A. To avoid removing concrete ooring, begin lineup

leveling from the highest point of the store oor.

B. When wedges are involved in a lineup, set them rst.

All cases were leveled and joined prior to shipment to

insure the closest possible t when cases are joined in

the eld. When joining, use a carpenters level and adjust

legs accordingly. The legs on the Q1-DC are adjustable

and do not require shims. Simply screw the leg up or down

to adjust height.

1. Using case blueprints, measure off and mark on the

oor the exact dimensions of where the cases will

sit. Snap chalk line for front and back positions of

base rail or pedestal. Mark the location of each joint

front and back. Find the highest point throughout the

lineup. FLOORS ARE NORMALLY NOT LEVEL!

Determine the highest point of the oor; cases will

be set off this point. All cases in the entire lineup

must be brought up to the highest level of the case

sitting at the highest point in the lineup. This may be

done a few different ways.

a) Walk the oor looking for any mounds or dips.

b) Use a string level.

c) Use a transit.

If a wedge is used in the middle of a lineup, the

wedge must be set on the highest point on the oor

FIRST, with the rest if the lineup being leveled from

it. The Q1-DC case has adjustable legs to allow for

leveling.

2. Set rst case over the highest part of the oor and

adjust legs so that case is level. Remove side and

back leg braces after case is set and joined.

3. Set second case within one foot (1’) of the rst case,

and remove leg skids. Keep the supports along the

length of the case and far end of case. Level case to

the rst using the instructions in step one.

4. Apply masking tape 1/8” in from end of case on

inside and outside rear mullion and body work on

both cases to be joined.