Boiler

Installation

If

the

controller

is

being

used

on

a

boiler

installation

test

it

as

follows

1

Note

the

boiler

pressure

by

checking

the

boiler

pres

sure

gauge

To

perform

this

testproperly

the

boiler

should

have

a

pressure

reading

near

the

middle

of

the

controller

s

main

scale

range

2

Turn

the

main

scale

adjusting

screw

Fig

11

until

the

m

rlnscale

setting

indicator

on

the

controller

corresponds

to

th

b9iler

pressure

gauge

readiri

g

3

TheL404A

or

C

should

break

the

control

circuit

s

automatically

when

the

boiler

pressure

gauge

reading

equals

or

slightly

exceeds

the

controller

setting

The

L404B

or

D

should

make

the

circliit

under

the

same

circumstances

The

L404F

L604L

M

should

inake

the

R

W

circuit

and

break

the

R

B

circuit

under

the

same

circumstances

The

L604A

should

make

the

RI

W

circuit

and

break

the

R2 B

circuit

under

the

same

circumstances

4

If

the

controller

is

operating

properly

turn

the

main

scale

adjusting

screw

Fig

11

until

the

main

scale

setting

indicator

is at

the

desired

set

point

If

a

Controller

Seems

to

Operate

Improperly

If

the

controller

is

suspected

of

operating

iniproperly

it

may

be

further

checked

as

follows

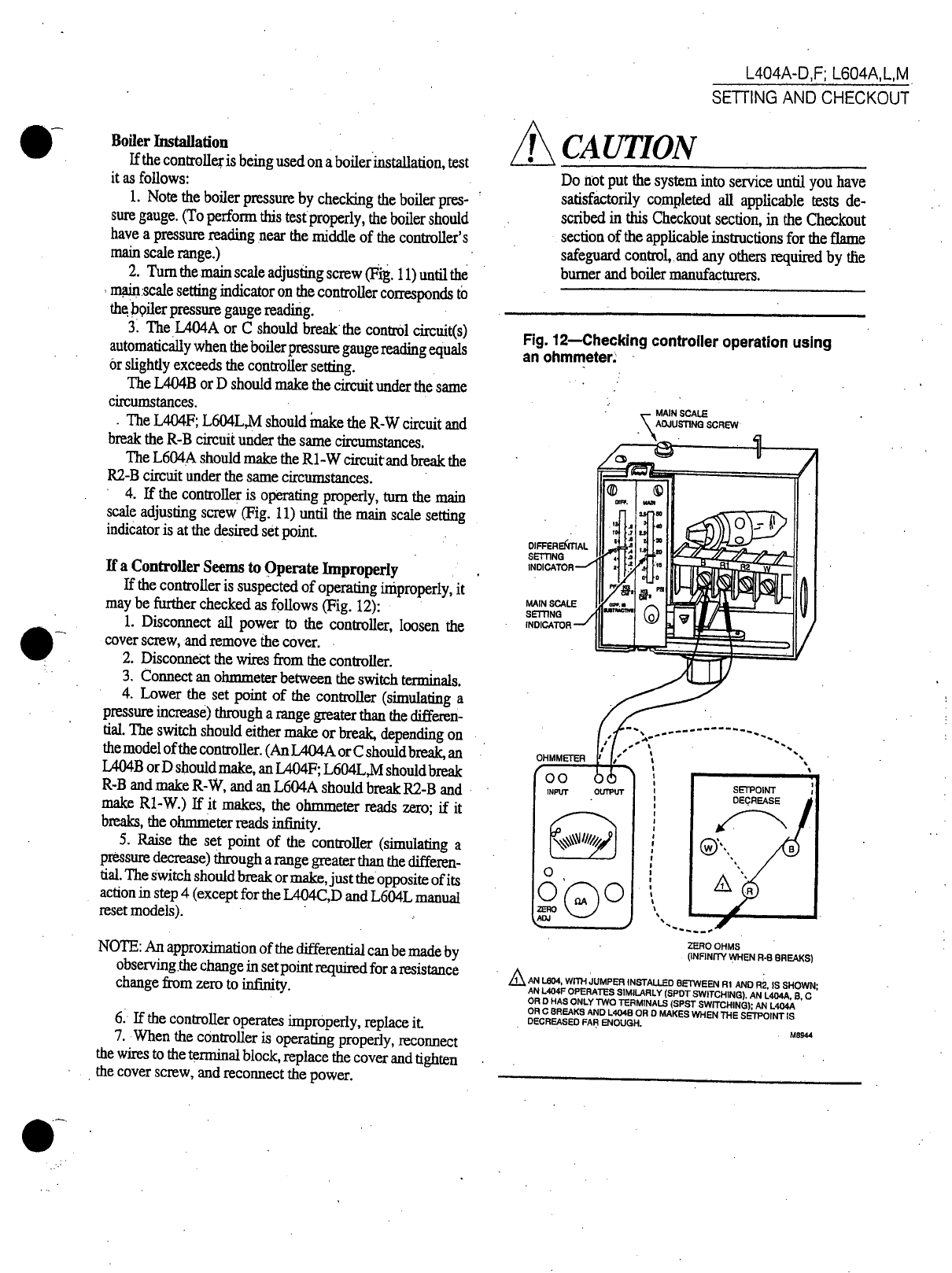

Fig

12

1

Disconnect

all

power

to

the

controller

loosen

the

cover

screw

and

remove

the

cover

2

DisconneCt

the

wires

from

the

controller

3

Connect

an

ohmmeter

between

the

switch

terminals

4

Lower

the

set

point

of

the

controller

simulating

a

pressure

increase

through

a

range

greater

than

the

differen

tial

The

switch

should

either

make

or

break

depending

on

the

model

of

the

controller

AnL404A

orC

should

break

an

L404B

or

D

should

make

an

IA04F

L604L

M

should

break

R

B

and

make

R

W

and

an

L604A

should

breakR2

B

and

make

RI

W

If

it

makes

the

ohmmeter

reads

zero

if

it

breaks

the

ohmmeter

reads

infinity

5

Raise

the

set

point

of

the

controller

simulating

a

pressure

decrease

through

a

range

greater

than

the

differen

tial

The

switch

should

break

or

make

just

the

opposite

of

its

action

in

step

4

except

for

the

L404C

D

and

L604L

manual

reset

models

NOTE

An

approximation

of

the

differential

can

be

made

by

observing

the

change

in

set

point

required

for

a

resistance

change

from

zero

to

infinity

6

If

the

controller

operates

improperly replace

it

7

When

the

controller

is

operating

properly

reconnect

the

wires

to

the

terminal

block

replace

the

cover

and

tighten

the

cover

screw

and

reconnect

the

power

L404A

D

F

L604A

L

M

SETTING

AND

CHECKOUT

ffi

CAUTION

Do

not

put

the

system

into

service

until

you

have

satisfactorily

completed

all

applicable

tests

de

scribed

in

this

Checkout

section

in

the

Checkout

section

of

the

applicable

instructions

for

the

flame

safeguard

control

and

any

others

required

by

tlie

burner

and

boiler

manufacturers

Fig

12

Checking

controller

operation

using

an

ohmmeter

MAIN

SCALE

SETllNG

INDICATOR

00

INPUT

OUTPUT

o

280

ADJ

MAIN

SCALE

ADJUSTlNG

SCREW

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

ro

SETPOINT

DEqREASE

ZERO

OHMS

INANITY

WHEN

R

B

BREAKS

AN

l

604

WITH

JUMPER

INSTALLED

BElWEEN

Rl

AND

R

IS SHOWN

AN

L404F

OPERATES

SIMIlJ

RL

Y

SPOT

SWITCHING

AN

L404A

B C

OR

0

HAS

ONLY

TWO

TERMINALS

SPST SWITCHING

AN

L404A

OR

C

BREAKS

AND

L404B

OR

0

MAKES

WHEN

THE

SETPOINT

IS

DECREASED

FAfl

ENOUGH

M8944