L404A

D

F

L604A

L

M

INSTALLATION

Mounting

on

a

Boiler

If

it

is

not

convenient

to

mount

the

controller

alongside

the

pressure

gauge

install

a

steam

trap

siphon

loop

in

the

fitting

provided

by

the

boiler

manufactUrer

If

there

is

no

fitting

mount

the

steam

trap

at

a

location

recommended

by

the

boiler

manufacturer

Screw

the

controller

directly

to

the

steam

trap

and

level

the

controller

Mounting

at

a

Remote

Location

If

there

is

excessive

vibration at

the

boiler

that

can

adversely

affect

the

operation

of

the

controller

mount

the

controller

at

a

remote

location

All

piping

from

the

boiler

must

be

suitable

and

solidly

mounted

The

piping

must

be

properly

pitched

to

drain

all

condensation

back

to

the

boiler

A

steam

trap

siphon

loop

must

be

mounted

be

tween

the

remote

piping

and

the

controller

Level

the

controller

after

installation

Supervision

of

Atomizing

Medium

Pressure

Air

or

Steam

L404B

When

air

or

steam

is used

as

an

atomizing

medium

in

an

oil

burner

system

authorities

having

jurisdiction

approval

bodies

and

codes

often

require

a

low

limit

to

prevent

opening

the

main

oil

valve

until

sufficient

atomizing

pres

sure

is

present

and

to

shut

down

the

system

when

the

atomizing

pressure

falls

too

low

The

L404B

is

recommended

for

this

application

It

makes

a

circuit

when

the

pressure

rises

to

the

set

point

and

breaks

when

the

pressure

falls

to

the

set

point

minus

the

differential

Fig

10

WlRING

1

DiscoDDe

t

the

power

supply

before

beginning

wiring

to

preventelectrical

shock

or

equipment

damage

2

Assume

all

wiring

complies

with

applicable

electrical

co

ordinances

and

regulations

Use

NEC

Class 1

line

voltage

wiring

3

Fornormalinstallations

use

moisture

resistant

No

14

wire

sUitable

for

at

least

1670

1

750C

when

you

are

using

the

controller

with

a

flame

safeguard

primary

control

or

at

least

1940F

900C

when

using

it

with

a

programming

control

4

For

high

temperature

installations

use

moisture

resis

tant

No

14

wire

selected

for

a

temperature

rating

above

the

maximum

operating

temperature

5

All

models

have

a

terminal

block

inside

the

cover

Fig

3

and

4

and

a

7 8

in

22

2

mm

hole

in

one

side

for

1

2

in

condui

cable

or

wires

Remove

the

front

cover

by

loosen

ing

tIi

e

screw

at

the

bottom

of

the

main

scale

6

Refer

to

Fig

5

through

9

for

typical

hookups

Follow

the

burner

or

boiler

manufacturer

s

wiring

diagram

if

pro

vided

7

Make

sure

the

loads

do

not

exceed the

Switch

Contact

Ratings

in

the

Specifications

section

8

Replace

the

front

cover

when

wiring

is

completed

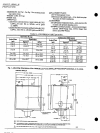

Fig

3

L404

terminal

blocks

and

internal

schematics

RISE

L404A

C

L404B

D

BREAKS

ON

PRESSURE

RISE

TO

SETPOINT

MAKE ON

PRESSURE

RISE

TO

SETPOINT

RISE

B

L404F

SNAP ACTING

BREAKS

R

a

MAKES

R

WON

PRESSURE

RISE

TO

SETPOINT

M8941

Fig

4

L404

terminal

block

and

Internal

schematic

L604A

L604L

M

MAKES

Rl

W

BREAKS

R2

8

ON

PRESSURE RISE

TO

SETPOINT

SPDT

SWITCH

ACTION

WITH

JUMPER

INSTALLED

M8935

OTHERWISE

TWO

ISOLATED

SPST SWITCHES

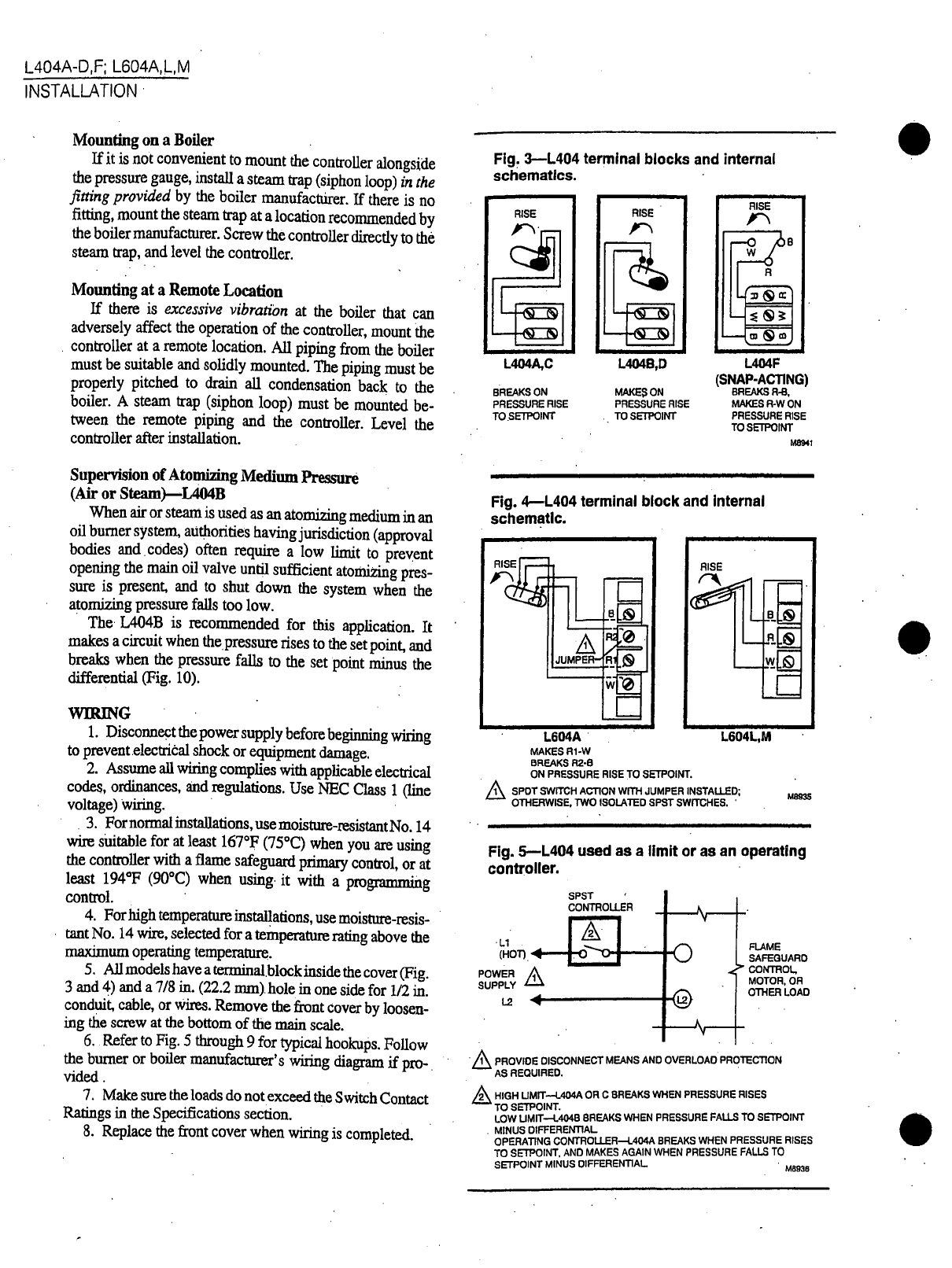

Fig

S

L404 used

as

a

limit

or

as

an

operating

controller

SPST

CONTROLLER

Ll

HOT

POWER

1

SUPPLY

Lll

U

FlAME

SAFEGUARD

CONTROL

MOTOR

OR

OTHER

LOAD

PROVIDE

DISCONNECT

MEANS

AND

OVERLOAD

PROTECTION

AS

REQUIRED

HIGH

UMIT

l

404A

OR

C

BREAKS

WHEN

PRESSURE

RISES

TO

SETPOINT

LOW

UMIT

t

4048

BREAKS WHEN

PRESSURE

FALLS

TO

SETPOINT

MINUS

DIFFERENTIAL

OPERATING

CONTROLLER

t

404A

BREAKS

WHEN

PRESSURE

RISES

TO

SETPOINT AND

MAKES

AGAIN WHEN

PRESSURE

FALLS

TO

SETPOINT

MINUS

DIFFERENTIAL

M8936