Important Guidelines

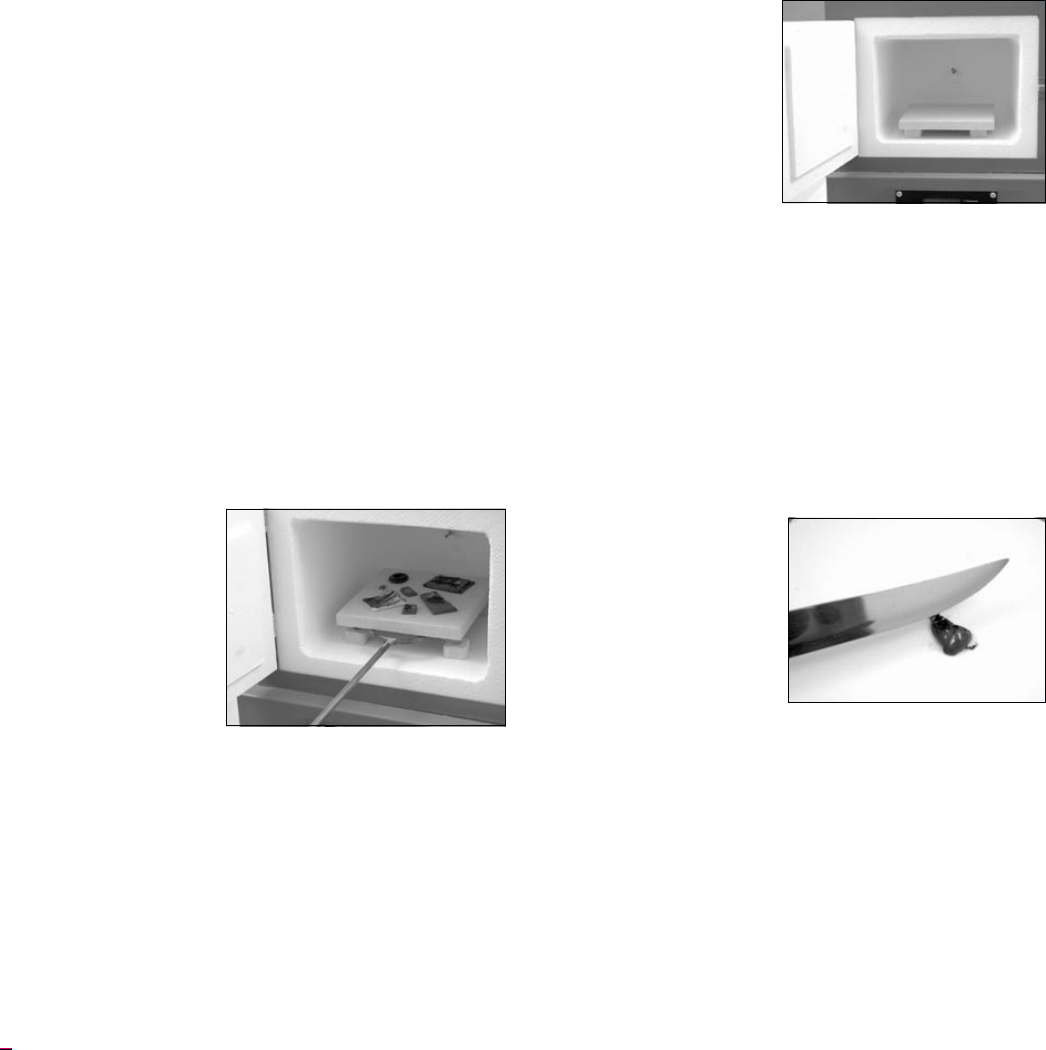

The Embedded Heating Element

The heating elements of your kiln are embedded into the

ceramic fiber firing chamber. The firing chamber surface is

hardened to a depth of ¼”. This makes the fiber more dura

-

ble. It is important that you do not touch the firing chamber

with sharp objects. These can penetrate the fiber surface

and contact the heating element, which is a shock hazard.

Note: The heating element under power is danger

-

ous. Do not touch the element with anything! Turn

the kiln switch off before inserting an enameling

fork into the firing chamber to remove a shelf.

The Clicking Noise

Do not be concerned if your kiln makes a clicking sound

during firing. Your kiln contains a relay, which sends power

to the element. The relay clicks as it cycles on and off to

maintain the correct temperature.

Check Thermocouple

You will find a small rod, called the thermocouple, ex

-

tending into the firing chamber. The digital controller

senses temperature by reading a voltage from the thermo-

couple. If this rod is pushed out of the firing chamber, the

kiln will assumethat the firing chamber iscold. This will re-

sult in an over-fire. Be sure the rod extends into the firing

chamber by ½” - ¾” before firing the kiln.

Vacuum the Kiln

Clean the kiln before firing glass, enameling, or ceramic

glaze. (Cleaning is not necessary when firing silver or gold

clay). Usea soft brushnozzle on avacuum cleanerto remove

dust from inside the kiln.

Removing Hot Ware

To remove hot ware

from the kiln, turn off

the kiln. Carefully slide

an enameling fork un

-

der the shelf. Place the

hot shelf on a large ce

-

ramic kiln shelf in front

of the kiln. Wear thick

work gloves.

Firing Log Book

Record the following information in a firing log book:

■

Date

■

Firing temperature, speed and hold; or Ramp/Hold pro

-

gram

■

Starting time

■

Total firing time

■

Type of pieces

■

Firing results

As you gain experience, you will find a wealth of informa

-

tion in your firing logs.

Low Temperature Holds

A low temperature hold (i.e. 200° - 300°F) is more diffi

-

cult to maintain than higher temperature holds (1400° -

1700°F). At low temperatures, turning on the heating ele

-

ment affects firing temperature to a larger degree than at

high temperatures.

When holding at a low temperature, heat the kiln slowly.

Otherwise the temperature may overshoot the hold temper

-

ature before the element turns off.

Avoid Contaminating the Heating Element

Contact with silica or

silica bearing com

-

pounds, such as kiln

wash, glass separator,

alumina hydrate, glass,

enameling powder, and

ceramic glaze, will ruin

the heating element.

Never fireglazed ceramic

ware, glass, or enameling

directly on the firing chamber bottom. Use a ceramic shelf

on short posts to protect the bottom from glaze drips, glass

and enameling powder.

Caution: Some kilns contain a heating element

embedded inthe bottom ofthe firing chamber.Ma-

terials such as glass and glaze, if absorbed into the

fiber firing chamber, can ruin the element. This

type of damage is not covered by warranty. Prevent

glass separator, kiln wash, and alumina hydrate

from falling from a shelf onto the firing chamber.

These materials can destroy the element.

Note: If a contami

-

nant such as dripping

glass or glazeembeds

into the firing cham

-

ber, unplug the kiln.

Gently scrape off the

contaminant with a

knife, being careful

not to damage the

heating element.Vac

-

uum the kiln.

The Effect of Silver Residue on Glass

Firing silver clay leaves traces of silver in the pores of the

firing chamber. Sometimes there isenough silver residue in

the kiln to affect colors of glass. For instance, green might

turn yellow.

Note: Before firing an important glass piece in a

kiln used for silver clay, perform color tests. Fire

small samples of each glass color on a base sheet of

clearglass. Placetheglassona fireclayshelf(notthe

soft fiber shelf).

6